Preparation method of graphene/oxidized graphene

A technology of graphene and acid graphite, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as difficult control of quality and yield, difficulty in large-scale preparation of graphene, etc., achieve important industrial application potential, obvious The effect of innovative theory and process, easy scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

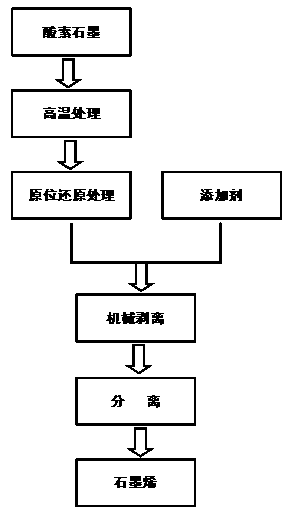

[0028] Take a certain amount of acid element graphite, treat it in the air at 1000°C for 1 hour, then in situ reduction treatment at 1000°C in the nitrogen-hydrogen mixture of 5.0% H2 for 1 hour, then add 2.0% polyethylene glycol by mass ratio and 2.0% by mass ratio Sodium dodecylbenzene sulfonate, mixed with water to form a slurry with a concentration of 80.0%, ball milled in a ball mill at 2000 rpm for 12 hours, separated by a high-speed centrifuge at 10,000 rpm, can be dispersed in an aqueous solution Good graphene. image 3 The microstructure morphology of the graphene prepared in this embodiment is shown.

Embodiment 2

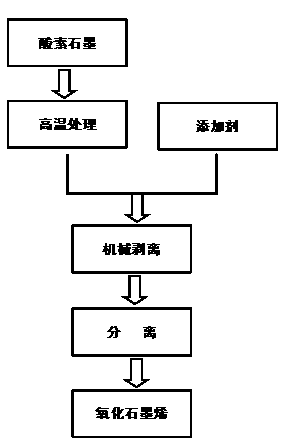

[0030] Take a certain amount of acid graphite, and treat it in the air at 1000°C for 0.5 hours, then add 2.0% by mass ratio of sodium methylcellulose and 2.0% by mass ratio of sulfonated polyaniline, and make a slurry with a concentration of 80.0% with water , in a ball mill at 2000 rpm for 10 hours, and separated by a high-speed centrifuge at 9000 rpm, graphene oxide with good dispersion in aqueous solution can be obtained. Figure 4 The microstructural morphology of the graphene oxide prepared in this example is shown.

Embodiment 3

[0032] Take a certain amount of acid element graphite and treat it in nitrogen at 1200°C for 1 hour, then in situ reduction treatment at 200°C in 10.0% H2 nitrogen-hydrogen mixture for 5 hours, then add sodium hexametaphosphate with a mass ratio of 0.05% and a mass ratio of 20.0 % of perylene tetracarboxylate, mixed with water to form a slurry with a concentration of 80.0%, grind it in a stirring mill for 12 hours, and separate it by a high-speed centrifuge at 10,000 rpm to obtain a good dispersion in aqueous solution. Graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com