Pasteurization tank of pouch food pasteurization machine

A pasteurizer and sterilization tank technology, which is used in packaging sterilization, conveyor objects, transportation and packaging, etc., can solve the problems of long heating and sterilization time, affecting the taste of food, etc., to improve the sterilization effect, improve practicability, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

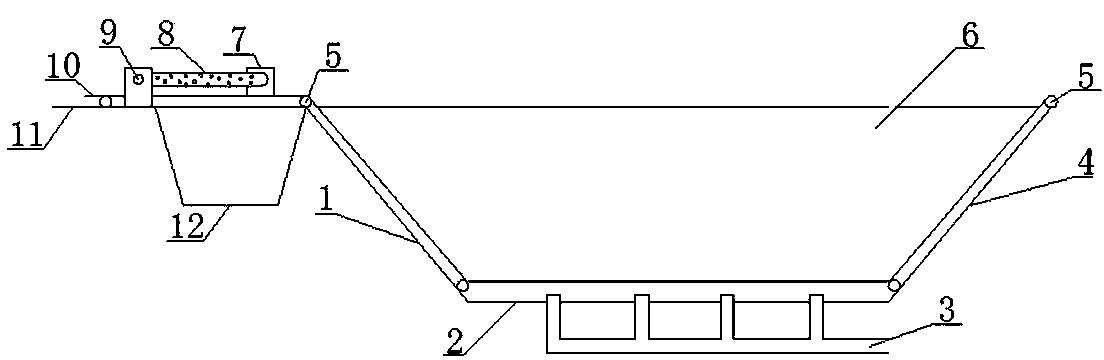

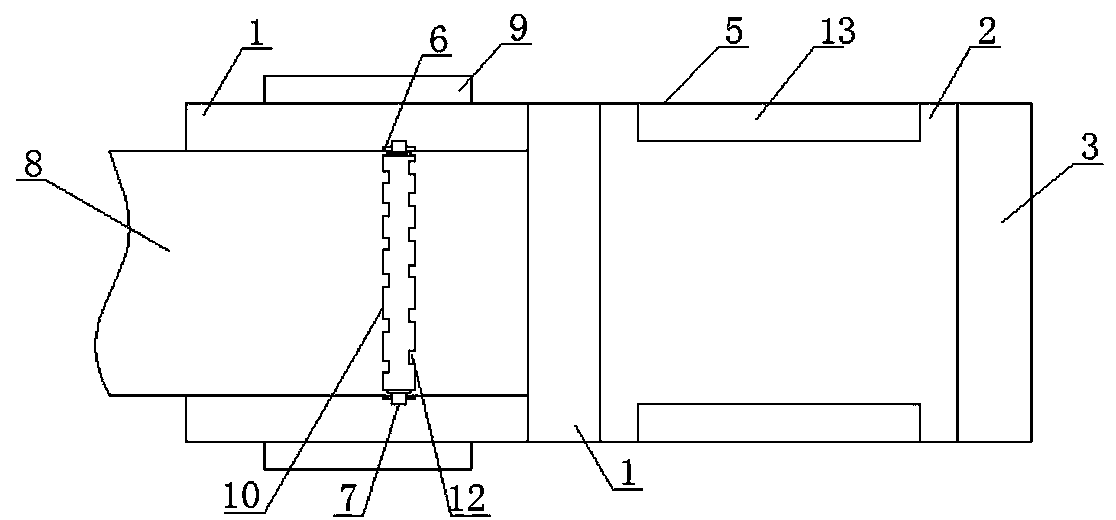

[0039] The sterilizing tank of the bagged food pasteurization machine of this embodiment comprises a bottom plate, two side plates and front and rear inclined plates, the bottom plate, two side plates, front inclined plates and rear inclined plates constitute a sterilizing tank, and the sterilizing tank is equipped with It is used to support the rollers of the conveyor belt; the two side panels are provided with at least two inclined baffles, and the baffles and the side panels form a channel, and the position of the baffle on the front section of the side panel is higher than the position of the baffle on the rear section of the side panel; The front inclined plate is connected with a horizontal support plate, the horizontal support plate is provided with rollers for supporting the conveyor belt, the support plate is provided with left and right symmetrical support frames along the conveyor belt, and the left and right support frames are connected with a As for the horizontal ...

Embodiment 2

[0041] The sterilizing tank of the bagged food pasteurization machine of this embodiment comprises a bottom plate, two side plates and front and rear inclined plates, the bottom plate, two side plates, front inclined plates and rear inclined plates constitute a sterilizing tank, and the sterilizing tank is equipped with It is used to support the rollers of the conveyor belt; the two side panels are provided with at least two inclined baffles, and the baffles and the side panels form a channel, and the position of the baffle on the front section of the side panel is higher than the position of the baffle on the rear section of the side panel; The front inclined plate is connected with a horizontal support plate, the horizontal support plate is provided with rollers for supporting the conveyor belt, the support plate is provided with left and right symmetrical support frames along the conveyor belt, and the left and right support frames are connected with a As for the horizontal ...

Embodiment 3

[0043] The sterilizing tank of the bagged food pasteurization machine of this embodiment comprises a bottom plate, two side plates and front and rear inclined plates, the bottom plate, two side plates, front inclined plates and rear inclined plates constitute a sterilizing tank, and the sterilizing tank is equipped with It is used to support the rollers of the conveyor belt; the two side panels are provided with at least two inclined baffles, and the baffles and the side panels form a channel, and the position of the baffle on the front section of the side panel is higher than the position of the baffle on the rear section of the side panel; The front inclined plate is connected with a horizontal support plate, the horizontal support plate is provided with rollers for supporting the conveyor belt, the support plate is provided with left and right symmetrical support frames along the conveyor belt, and the left and right support frames are connected with a As for the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com