Device used for automatically carrying aluminum section bars

An aluminum profile, automatic technology, used in transportation, packaging, conveyors, etc., can solve the problems of inability to meet production needs, low work efficiency, and high labor intensity of workers, and achieve strong market value, high production efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

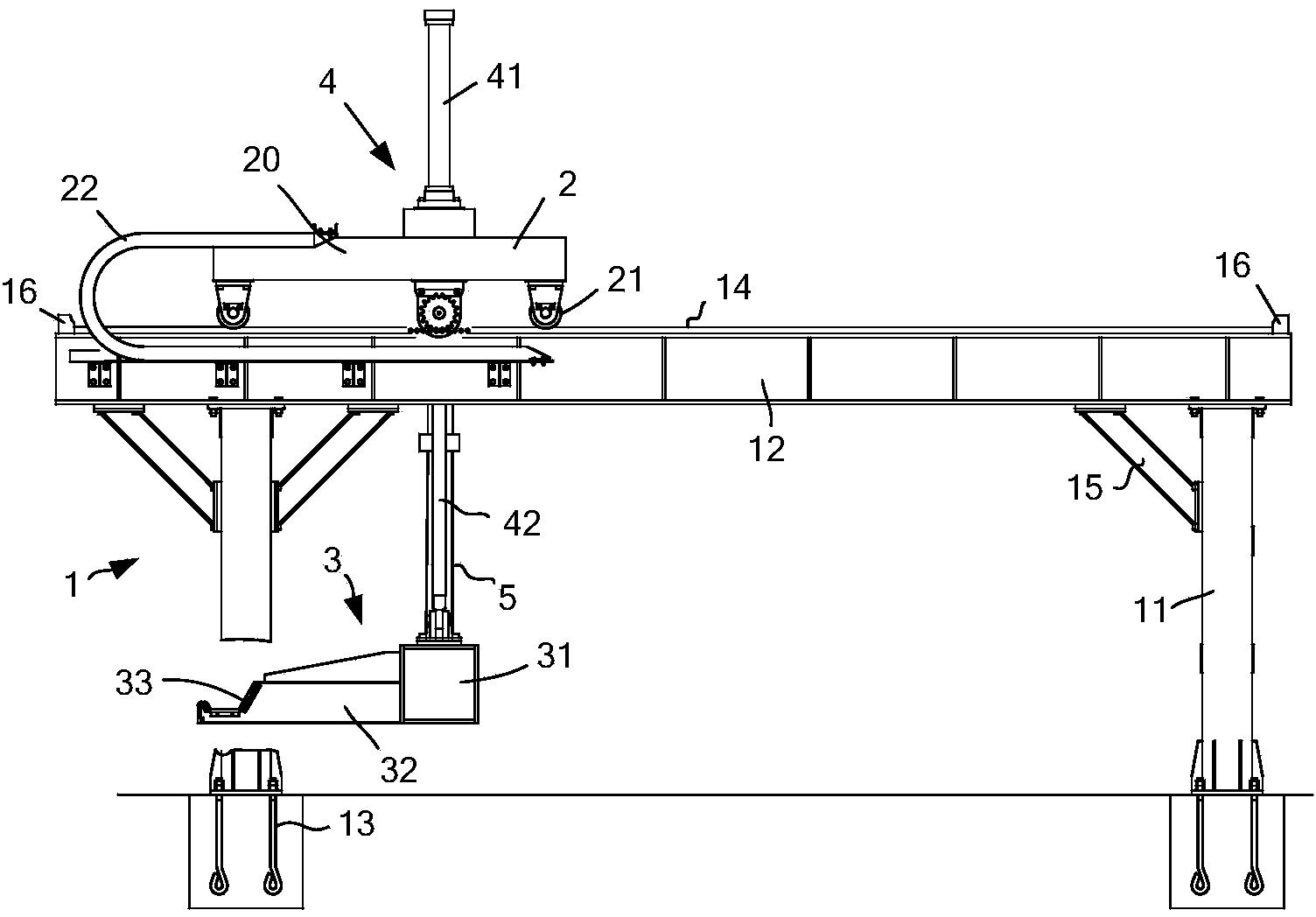

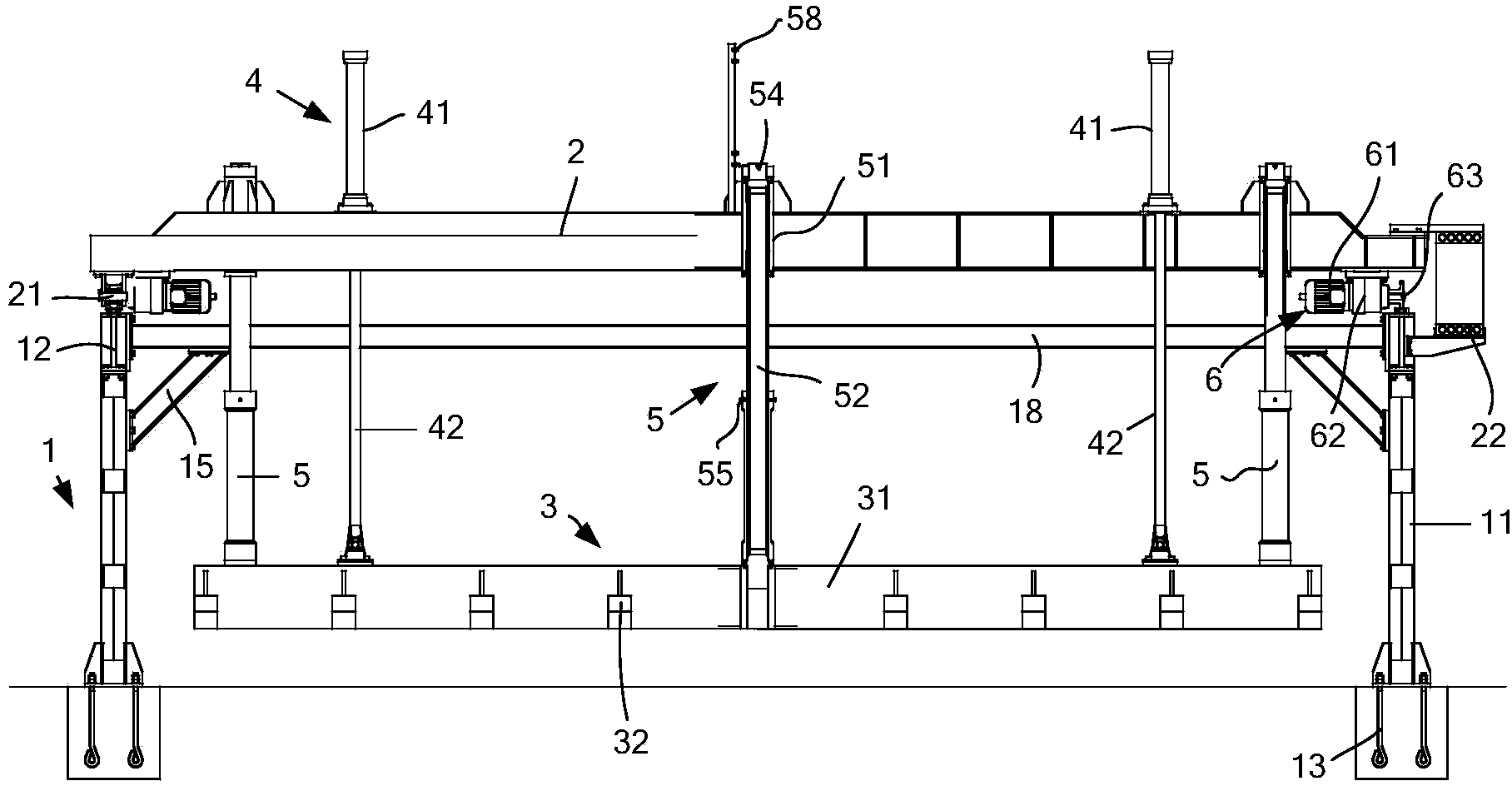

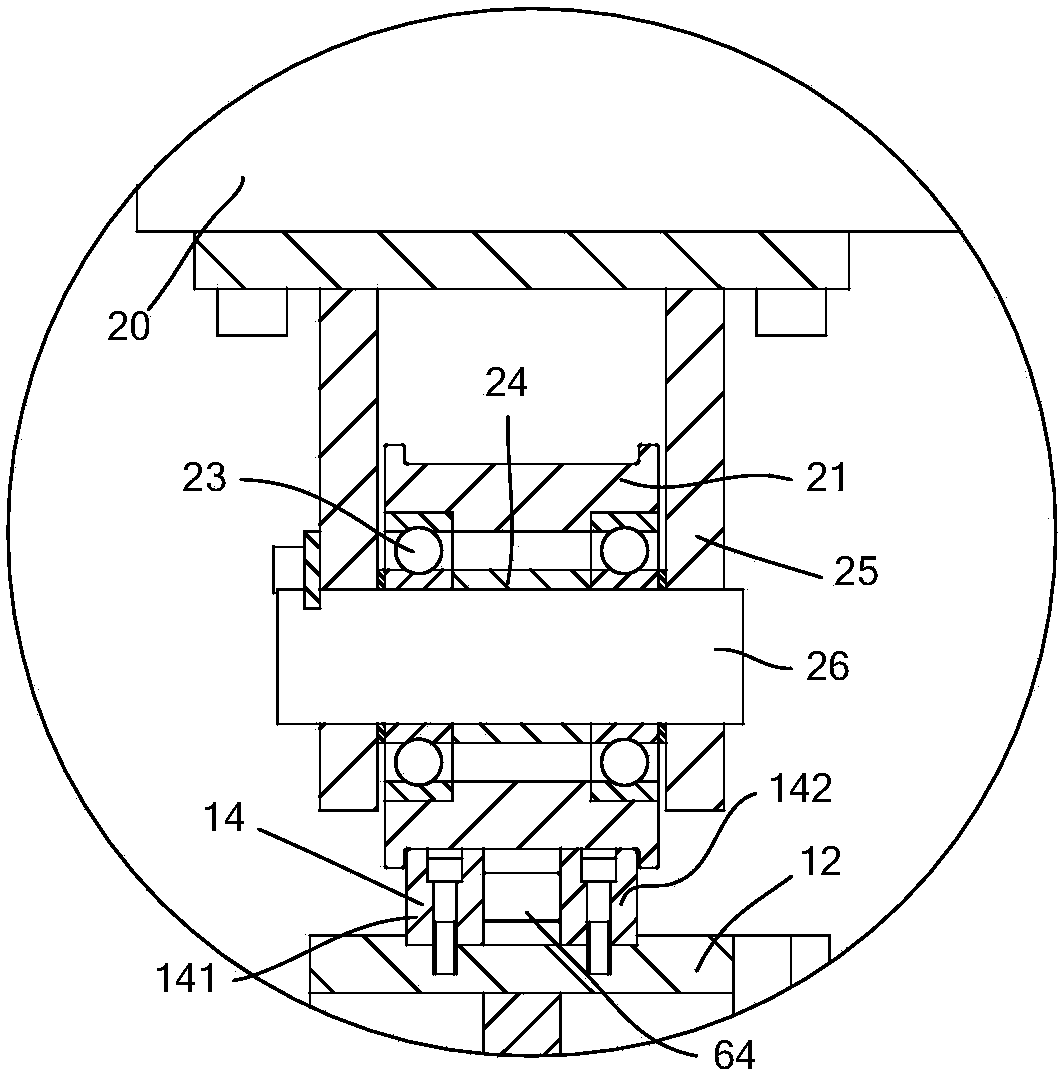

[0031] Such as figure 1 and figure 2 As shown, the device for automatic handling of aluminum profiles of the present invention includes: a support 1 , a moving trolley 2 , a material fork frame 3 , a hydraulic cylinder 4 , a guiding device 5 and a driving device 6 .

[0032] The bracket 1 includes a column 11 , a longitudinal beam 12 , an anchor bolt 13 , a guide rail 14 , a reinforcing frame 15 , two limiting blocks 16 and an auxiliary beam 18 . There are four columns 11, welded structure (upper and lower end plates, main body double-channel steel butt weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com