A kind of gluing process for cyclone overflow pipe

A technology for overflow pipes and cyclones, which is applied in the field of viscose glue for cyclone overflow pipes, can solve problems such as the shortening of the life of overflow pipes, achieve the effect of solving glue opening wear and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A gluing process for a cyclone overflow pipe, the cyclone overflow pipe is a metal round pipe with a connecting flange, comprising the following steps,

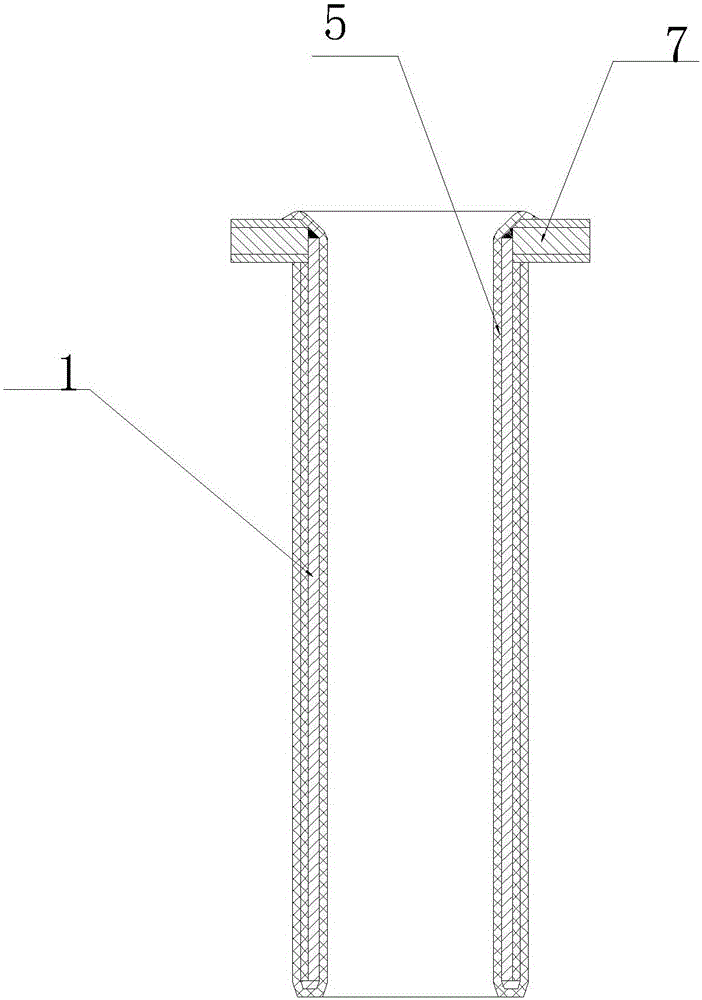

[0020] Step (1): making a long cylindrical rubber 5 whose length is equal to that of the metal circle

[0021] tube

[0022] The sum of the length of the rubber layer to be bonded on the surface and the outer surface;

[0023] Step (2): first bond the long cylindrical rubber 5 to the inner surface of the metal tube, and then flang the long tube rubber protruding from the bottom of the metal tube; the length of the flanging is 20mm.

[0024] Step (3): After brushing glue on the outer surface of the metal round tube, pull the long cylindrical rubber 5 that is flanged outward to one end of the flange 7, and glue the outer surface of the metal round tube 1 with rubber Floor.

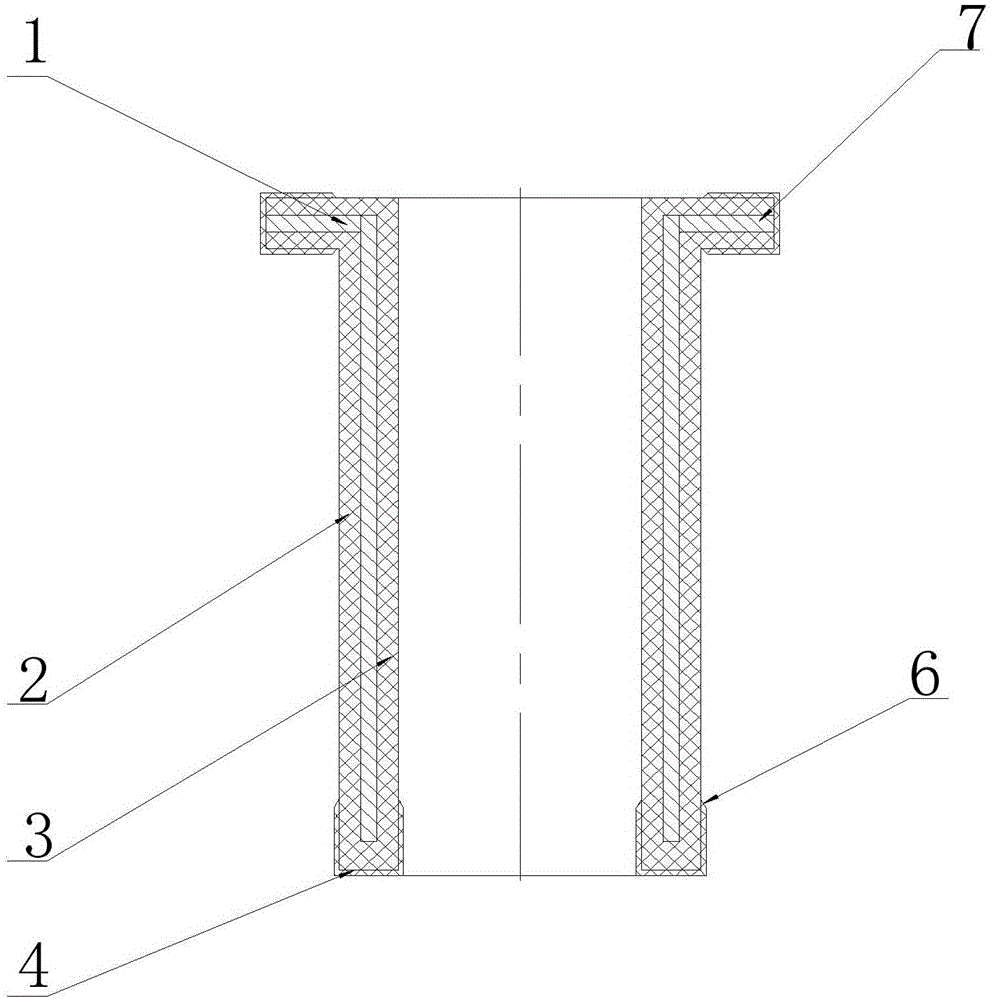

[0025] like figure 2 As shown, a cyclone overflow pipe prepared by a hydrocyclone overflow pipe viscose process includes a metal round pipe 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com