High-speed train front window glass installation device and method

A front window glass and installation device technology, which is applied to the surface coating liquid device, grinding machine, metal processing, etc., can solve the problems of uneven force on the glass, stress concentration, and insufficient glue coating, etc., to avoid stress, The effect of avoiding bursting and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

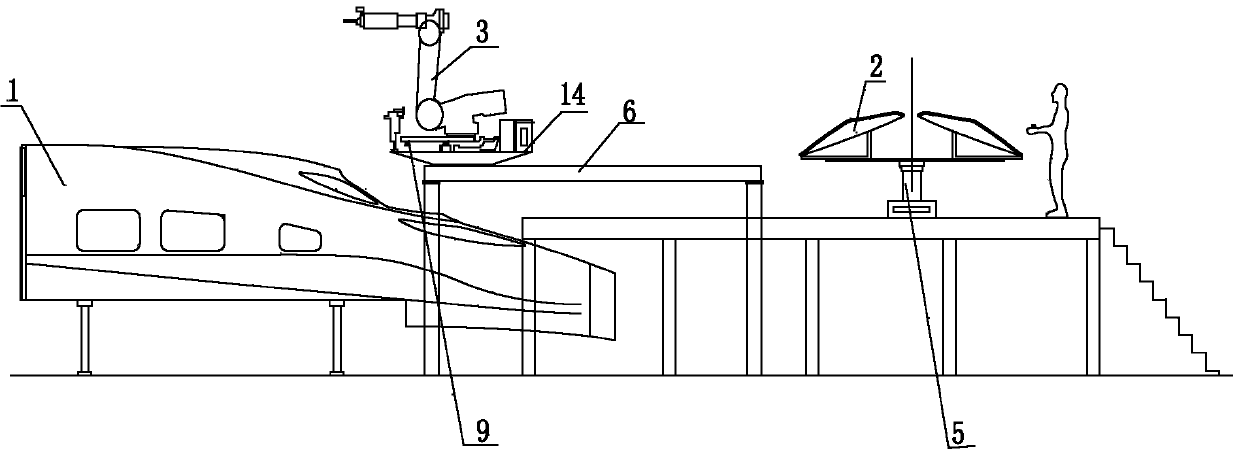

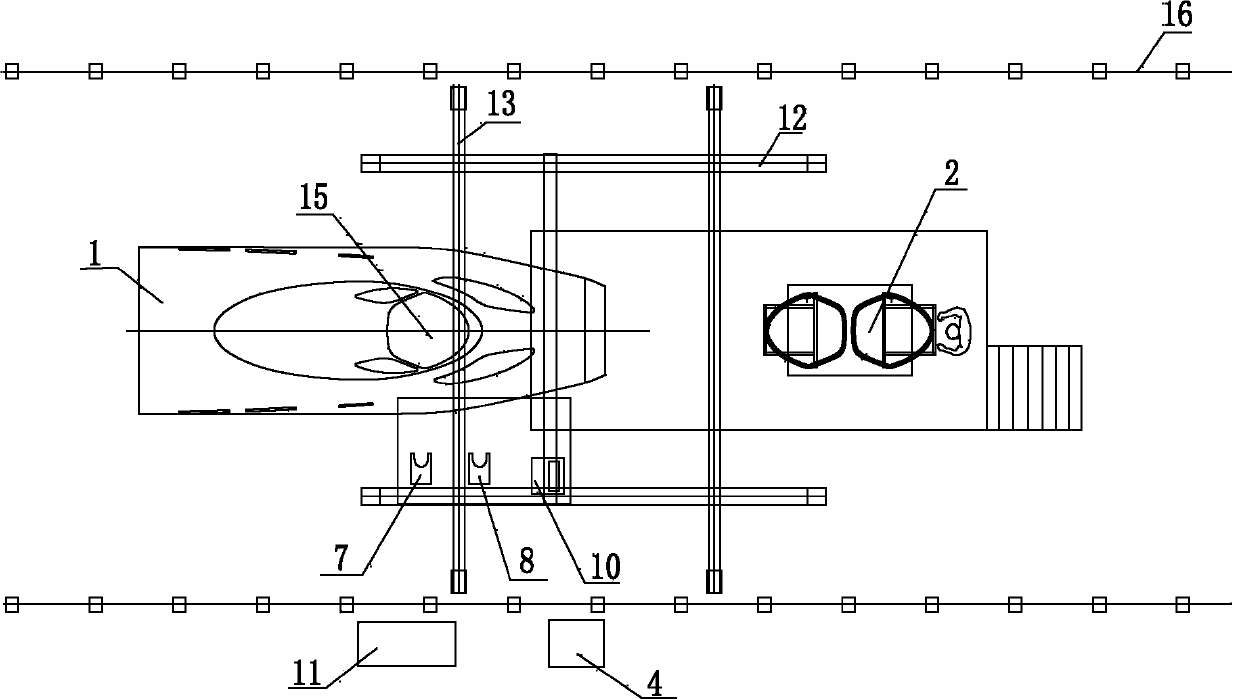

[0037] like figure 1 and figure 2 As shown, a high-speed motor car windshield installation device is used to realize the automatic installation of the windshield 2 located on the front 1.

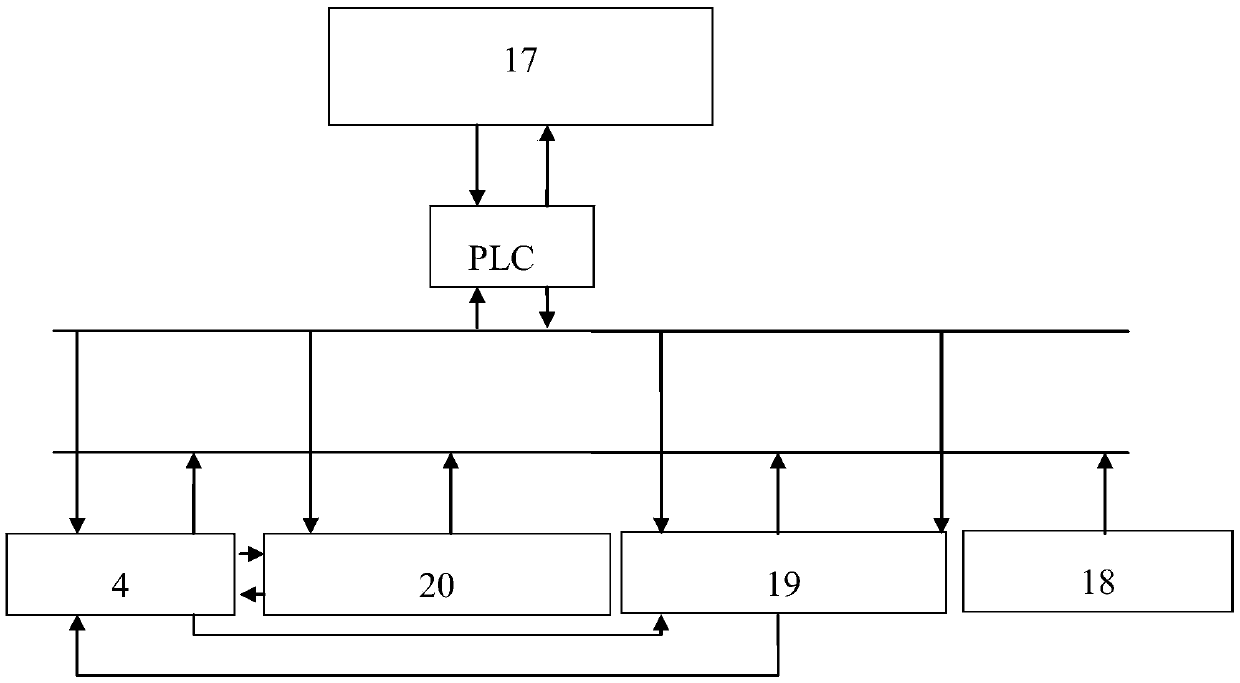

[0038] The installation device includes a robot body 3 , a robot control device 4 , a glass feeding platform 5 , a walking device 6 , a measuring and positioning device 7 , a grinding device 8 , a grabbing device 9 , a glue coating device 10 and a central control system 11 . The entire installation device can be fixed on a construction platform (not shown in the figure) or directly on the floor of the workshop.

[0039] Wherein, the robot body 3 adopts a robot with six degrees of freedom joints, the robot body 3 is connected to the robot control device 4, the robot control device 4 is connected to the central control system 11, and the robot control device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com