A radial drilling machine

A technology of radial drilling machine and right rocker arm, which is applied to the parts of boring machine/drilling machine, boring/drilling, drilling/drilling equipment, etc., which can solve the problems of reduced rigidity of the outer column and achieve increased performance and simplified structure , easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

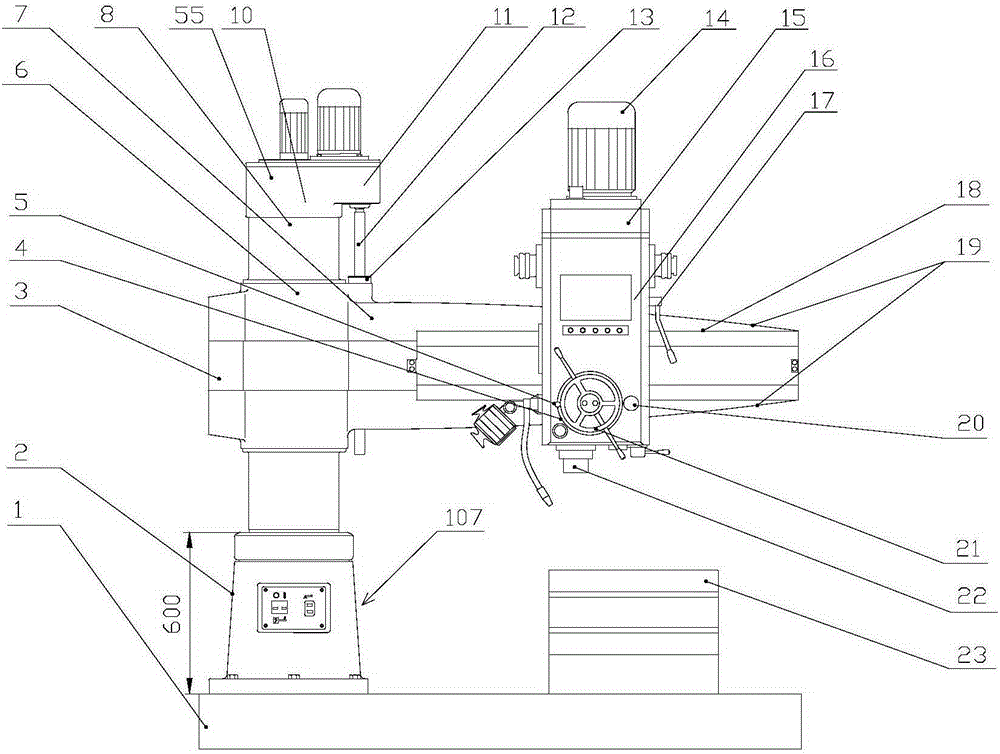

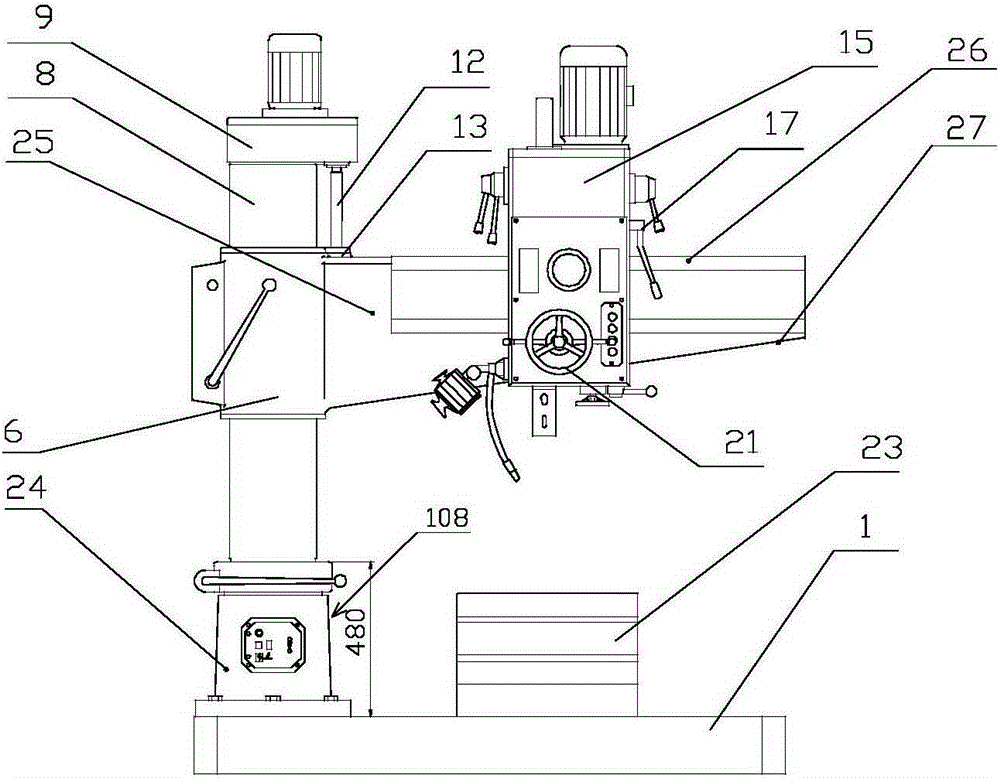

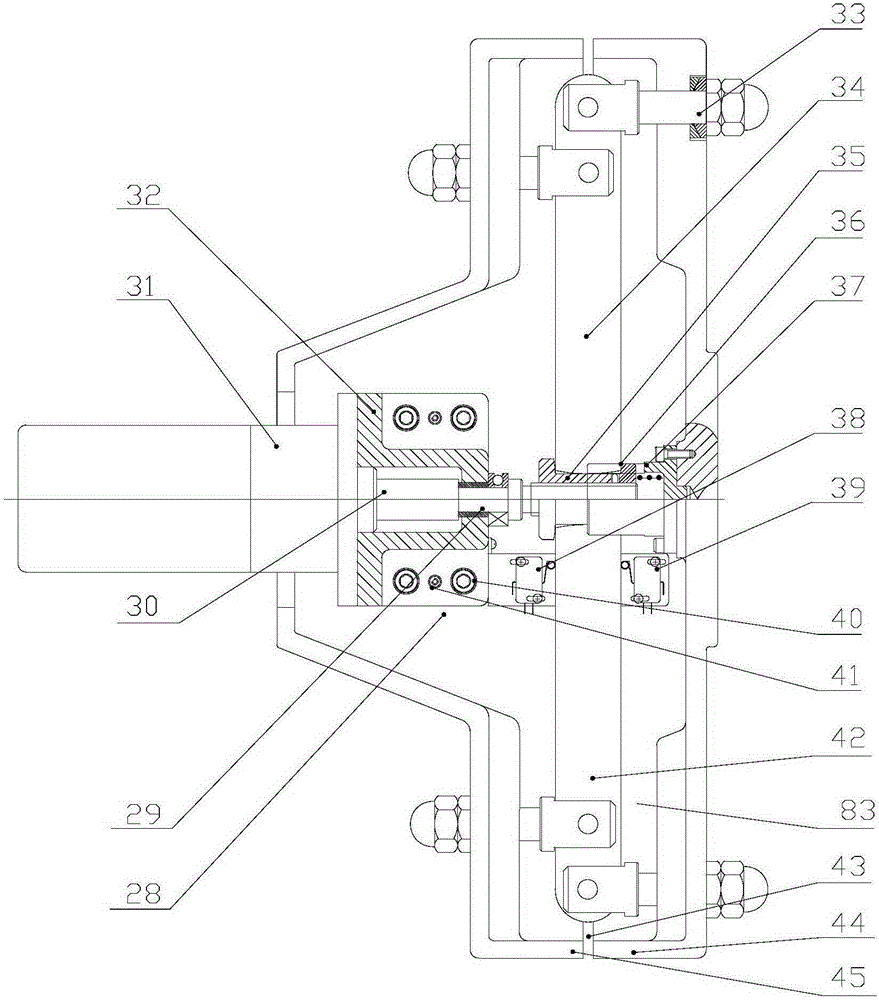

[0050] 1. As shown in Figure 1(a) and image 3 As shown, the radial drilling machine is mainly composed of a base 1, an inner column 2, a rocker arm 7, an outer column 8, a reduction box 55, a spindle gearbox 15, and a workbench 23. The specific structure is as follows:

[0051] The workbench 23 is fixed on one end of the base 1, and the inner column 2 is fixed on the other end of the base 1. The height of the root 107 of the inner column is 600 mm. Rotate ±180 degrees. One end of the rocker arm 7 is a rocker arm sleeve 6, and the rocker arm sleeve 6 is set on the outside of the outer column 8. The rocker arm sleeve 6 and the outer column 8 form a screw through the rocker arm lifting screw 12 and the lifting screw nut 13 used in conjunction. The screw nut matching structure is driven by the reduction box 55 on the top of the outer column 8, so that the rocker sleeve 6 can move up and down along the outer column 8, and the column clamping device 10 and the rocker lifting safet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com