Special equipment for deburring of hub valve hole

A special equipment, valve hole technology, applied in the directions of transportation, packaging, vehicle parts, etc., can solve the problems of high labor intensity, different proficiency, low deburring efficiency, etc., and achieve the effect of reducing labor intensity, stable quality and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

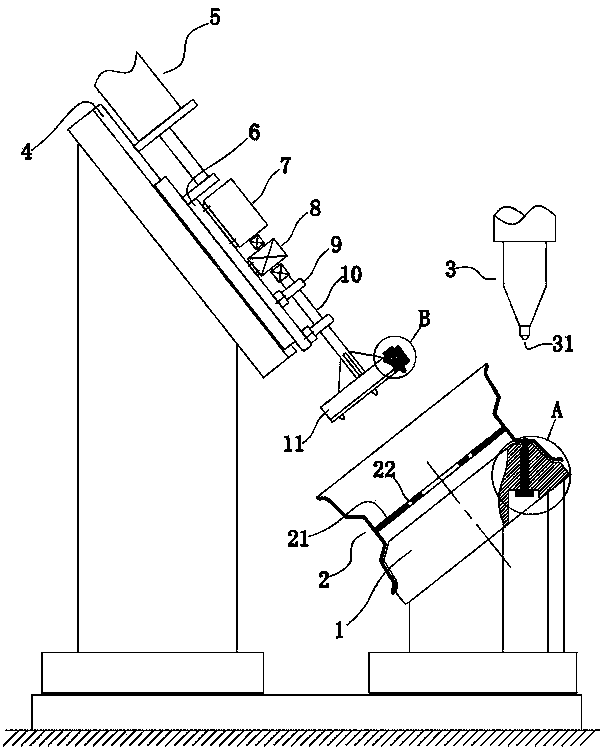

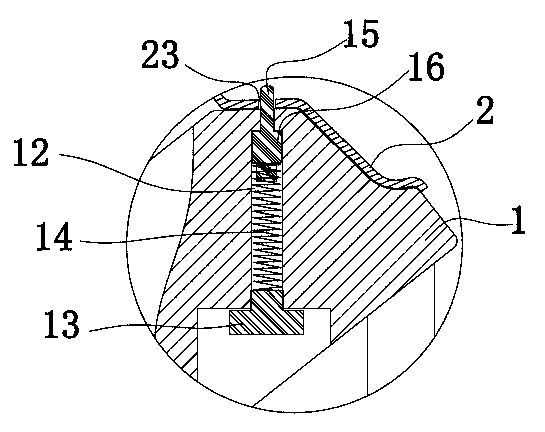

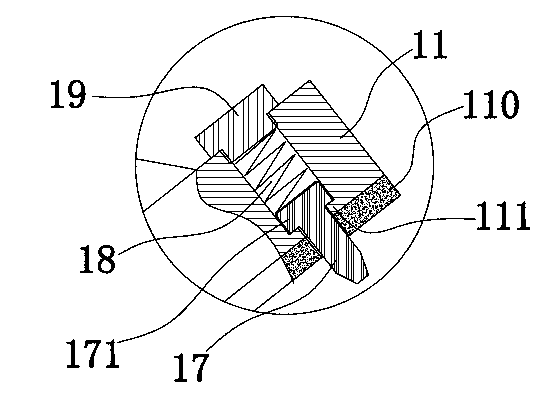

[0027] Such as figure 1 , figure 2 As shown, a special equipment for deburring the valve hole of a wheel hub, including a machine table, an annular lower die table 1 arranged on the machine table and matched with the inner peripheral surface of the wheel hub 2, and a punch 3 located above the annular lower die table. A vertical hole 12 corresponding to the valve hole 23 of the wheel hub 2 is provided on the outer peripheral surface of the annular lower mold table 1 . The angle between the centerline of the vertical hole 12 and the centerline of the annular lower mold table 1 is the same as the angle between the axis of the hub 2 and the centerline of the valve hole 23 . The vertical holes 12 are arranged vertically. The vertical hole 12 is a stepped through hole with a circular cross-section, and the cross-sectional area of the stepped thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com