Oil-gas separator

A technology of oil-gas separator and mixed gas, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., and can solve problems such as filter clogging and increased maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

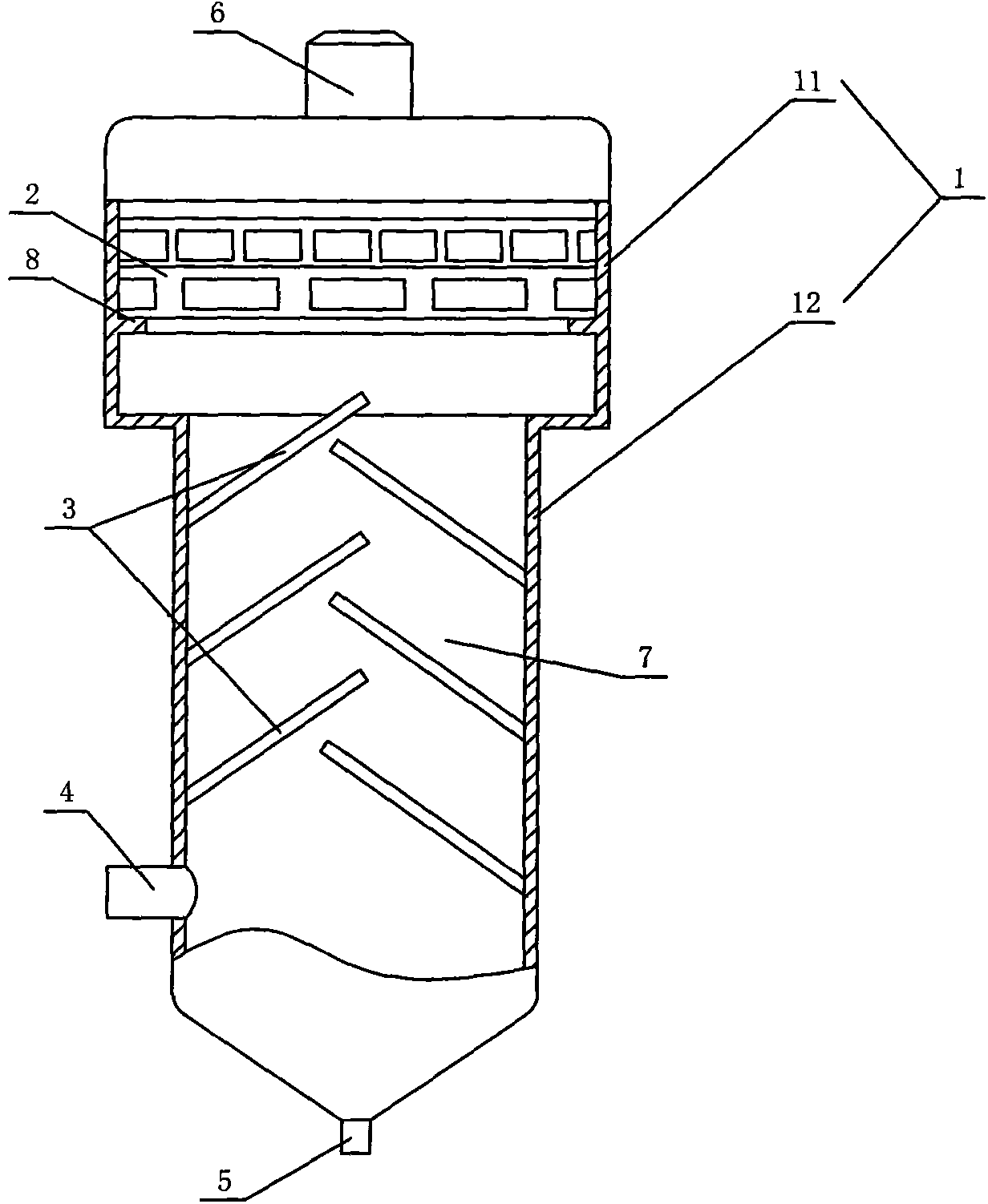

[0011] like figure 1 The shown oil-gas separator comprises a cylindrical outer shell 1, the outer shell 1 is composed of upper and lower sections with unequal diameters, the diameter of the lower shell 12 is smaller than the diameter of the upper shell 11, and the lower shell 12 The lower part of the casing is provided with a mixed gas inlet 4, the bottom is provided with an oil discharge port 5, the top of the upper casing 11 is provided with a waste gas outlet 6, and the lower part of the inner cavity of the lower casing 12 is fixed with opposite inclined upwards and arranged at staggered intervals. The multi-block baffles 3, the protruding ends of the multi-block baffles 3 are overlapped on the vertical projection, that is, the baffles 3 protrude obliquely upward from the connection end to the inner cavity of the outer shell 1, and the baffles 3 can be made of thin Made of stainless steel strips or plastic sheets, the bottom baffle 3 is located above the gas mixture inlet 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com