Chicory sliced bread and making process thereof

A technology of chicory sliced bread, sliced bread, applied in the direction of dough processing, baking, baked goods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

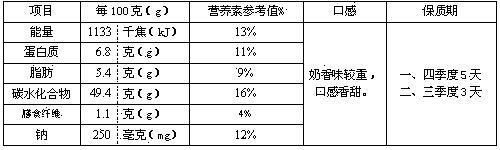

Embodiment 1

[0023] The specific production steps are as follows:

[0024] ——Preparation of chicory powder: Wash the chicory and cut into pieces to dry under natural conditions. Use a drum oven at a temperature of 140-160°C to bake for 20-30 minutes until golden yellow, and then use the The powder machine is made into powder, passed through a sieve of more than 200 mesh, and set aside;

[0025] ——Dough making: Mix water and chicory powder evenly for later use, then pour high-gluten flour, chicory syrup, inulin, yeast, white sugar, face powder, milk powder, eggs, improver, and baking powder into the mixing tank, according to Stir at a medium speed for 1-2 minutes. After the dough is formed, stir at a high speed of 300 rpm until it expands to eight minutes, then add salt and stir at a medium speed for 1-2 minutes. When the salt is completely integrated into the dough, add ghee and continue to stir at a slow speed , until the ghee and the dough are completely blended, then stir at a high spe...

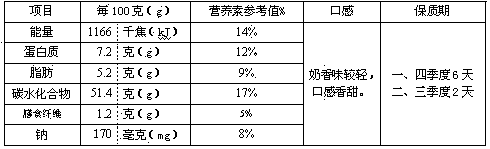

Embodiment 2

[0033] The specific manufacturing steps are the same as in Example 1, and the finished product is finally obtained.

[0034] This chicory sliced bread is carried out the detection of nutritional labeling, taste and shelf-life, and concrete results are shown in Table 2:

[0035] Table 2: Nutrients, mouthfeel and shelf life table of sliced chicory bread in embodiment 2

[0036]

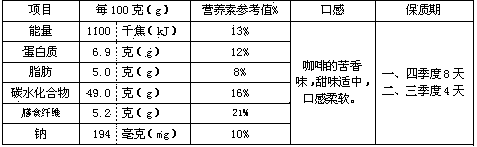

[0037] Example 3

Embodiment 3

[0039] The specific manufacturing steps are the same as in Example 1, and the finished product is finally obtained.

[0040] This chicory sliced bread is carried out the detection of nutritional labeling, taste and shelf-life, and concrete results are shown in Table 3:

[0041] Table 3: Nutrients, mouthfeel and shelf life table of sliced chicory bread in embodiment 3

[0042]

[0043] Comparative example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com