Brake assembly of mute tubular motor

A tubular motor and brake component technology, applied in the field of brake components, can solve the problems of slow start, large brake disc, long braking time, etc., and achieve the effects of easy processing, sensitive braking and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

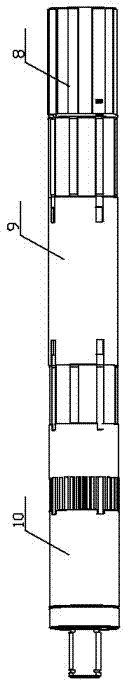

[0024] Such as figure 1 As shown, the motor 9 adopts a coaxial bidirectional output structure, the brake assembly is installed at the tail of the motor 9 , and the reducer assembly 10 and the power output part are installed at the head of the motor 9 .

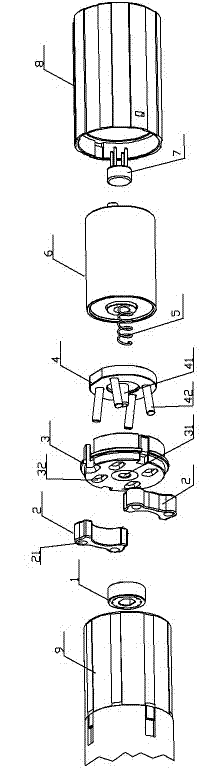

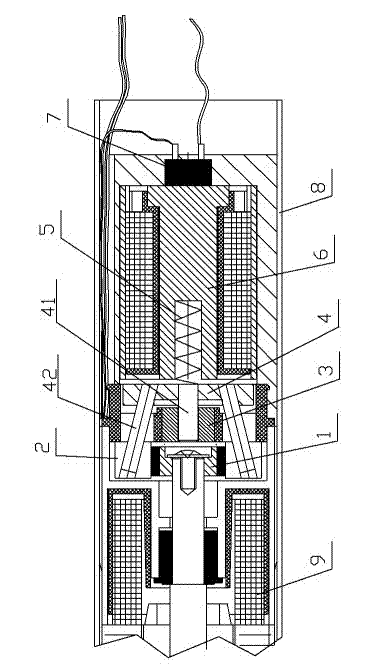

[0025] The brake assembly consists of a brake disc 1, a brake pad 2, a fixed seat 3, an armature seat 4, a spring 5, an electromagnet 6, a bridge stack 7 and a brake sleeve 8, such as figure 2 and image 3 As shown, the brake sleeve 8 is meshed with the casing teeth of the tubular motor 9, and other components are installed inside the brake sleeve. The outside of the brake sleeve 8 is provided with an anti-rotation groove.

[0026] Brake disc 1 is installed on the rotating shaft 11 of motor, fits by key, and is fixed by screw. A friction layer is arranged on the outside of the brake disc, and the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com