Automatic control device of drying roller

An automatic control device, the technology of squeezing rollers, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of wear and tear of the squeezing rollers, and achieve the advantages of reducing wear, prolonging the service life and improving the squeezing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

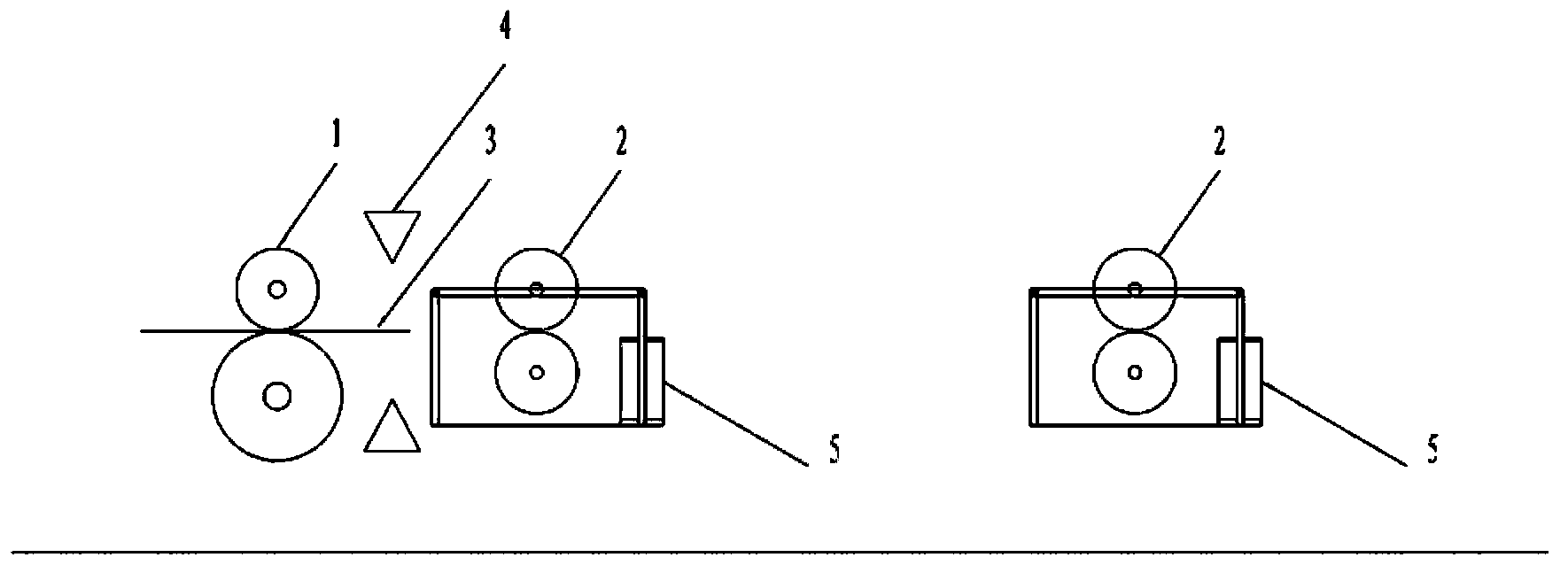

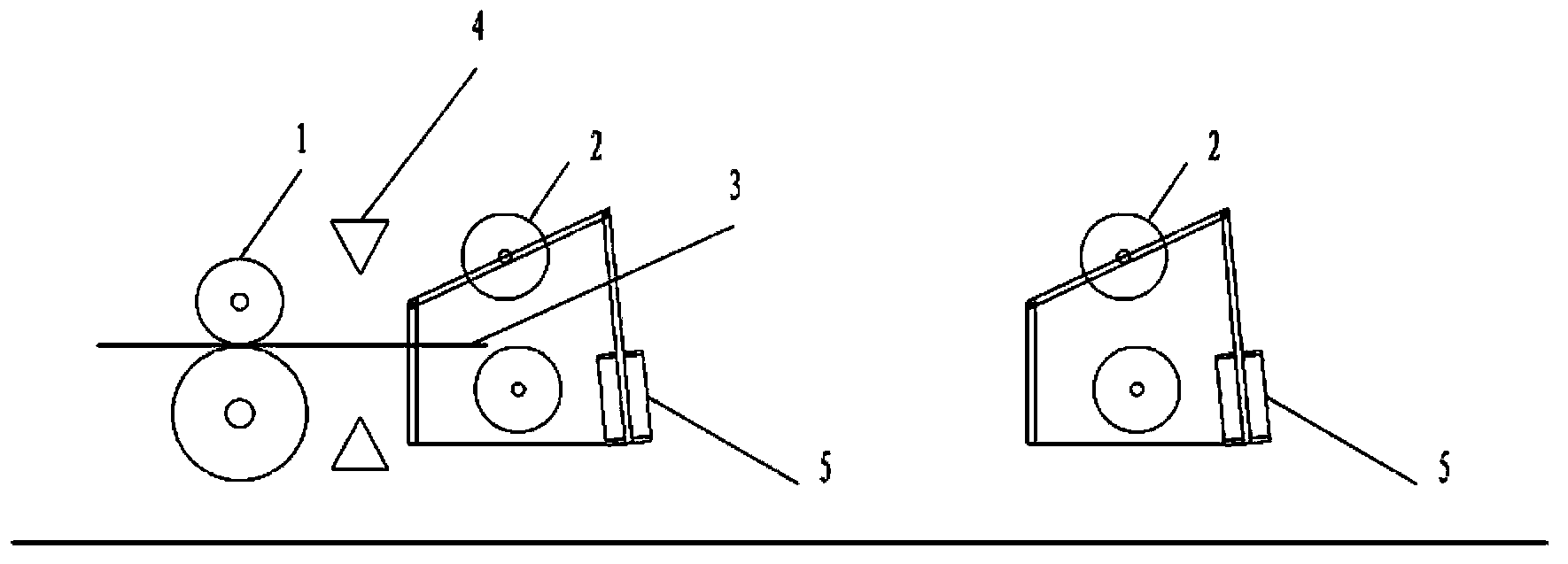

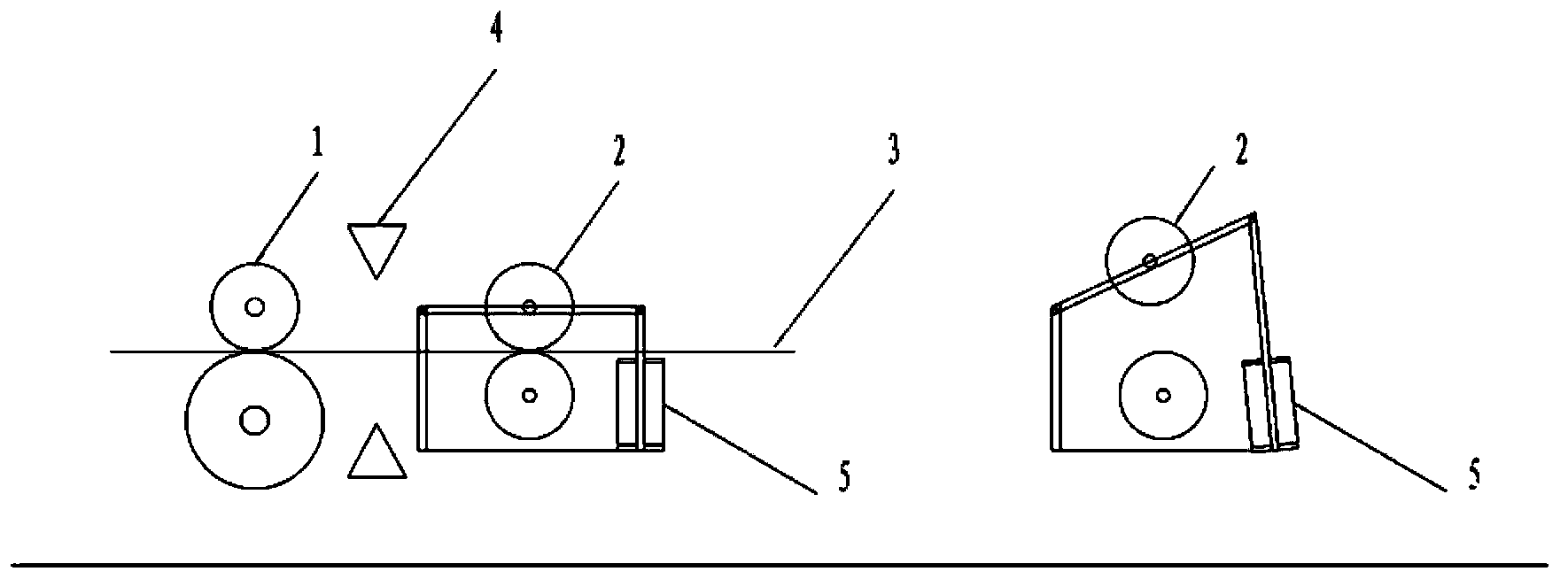

[0013] in the attached Figure 2-Figure 4 An automatic control device for squeezing rollers in a cleaning treatment line, including a pinch roller 1, a squeezing roller 2, a strip 3, a detection element 4 and an actuator 5, wherein the detection element 4 is installed on the pinch roller 1 and Between the squeeze rollers 2 , the strip 3 passes through the pinch roller 1 , the detection element 4 and the squeeze roller 2 in sequence.

[0014] figure 1 Among them, the squeezing roller 2 is composed of upper and lower rollers, wherein the lower roller is fixedly installed on the base, and the upper roller is installed on the bracket; the upper roller of the squeezing roller 2 can be lifted up with the bracket. In this device, the pinch roller 1 is used as the length measuring roller, the position of the detection element 4 is the starting point of length measurement, and the detection element 4 cooperates with the pinch roller 1 to control the stroke of the actuator 5 . After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com