Self-connected double roller weighing device

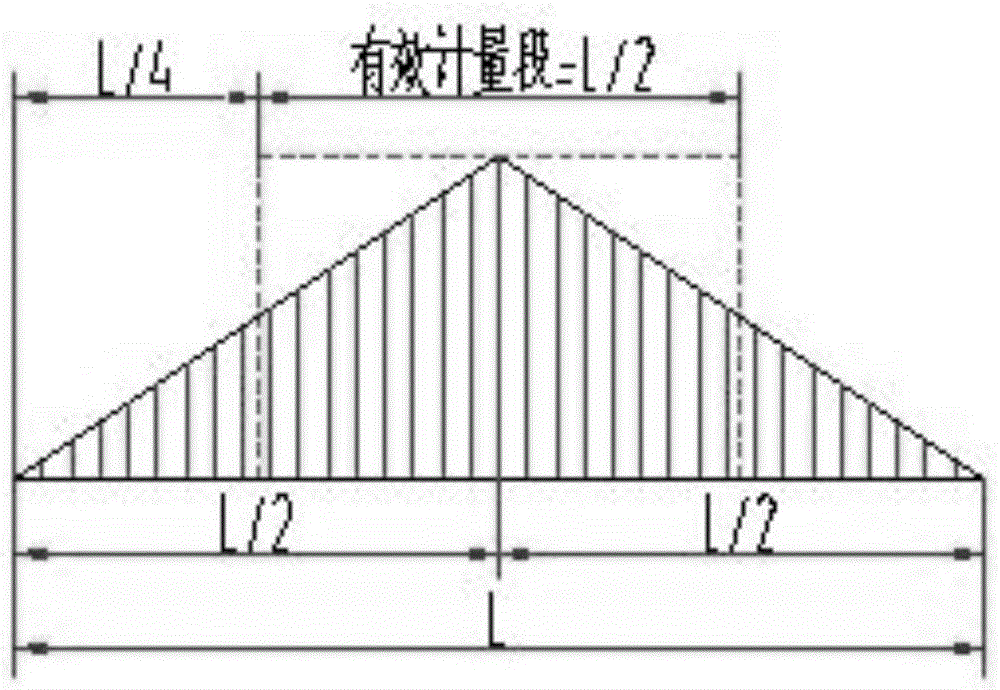

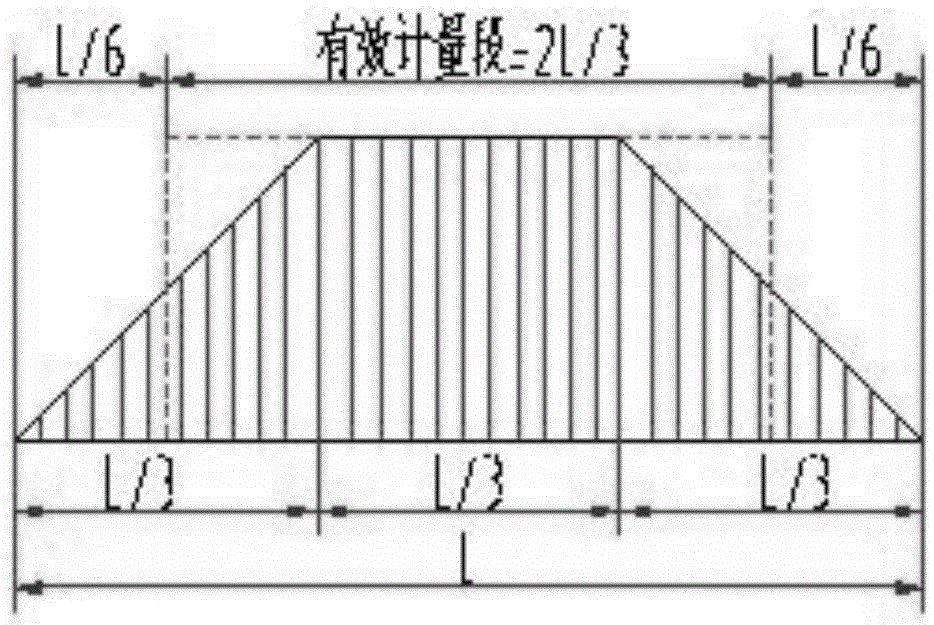

A technology of weighing device and idler, which is applied to measuring device, weighing device of continuous material flow, weighing and other directions, can solve the problems of unable to meet the transformation of idler weighing platform, heavy frame weighing platform, complex structure, etc. Achieve the effect of increasing the length of the effective metering section, improving the metering accuracy and long-term stability, and increasing the weight of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

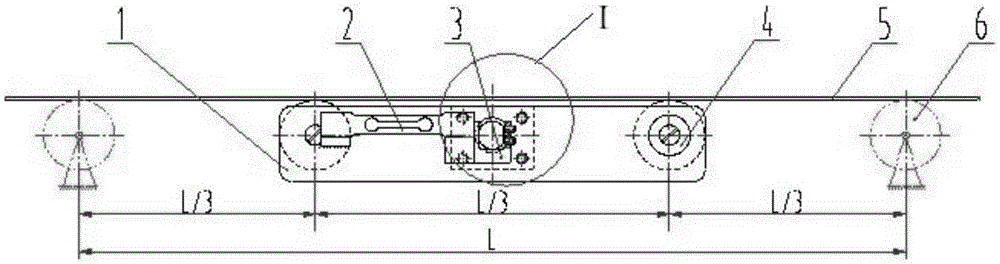

[0016] image 3 , Figure 4 , Figure 5 Shown, be the form of an electronic belt scale weighing platform that single group of the present invention and two groups of transition rollers 6 form. The self-connecting double roller weighing device of the present invention includes a rectangular frame composed of two parallel rollers 7 connected to two parallel connecting plates 1, and two small shafts 9 respectively installed in the middle of the two connecting plates. , two small shaft fixing seats 3 respectively arranged on the outside of the connecting plate, and the two small shaft fixing seats are respectively connected with the load-bearing end of the load cell 2 . The idler roller consists of a hollow tube 7b, a cylinder 7c set outside the hollow tube, shaft heads 7a at both ends and bearings 8, the shaft heads 7a at both ends are respectively welded with the ends of the hollow tube 7b to form a mandrel, and the bearings 8 are set on On the shaft head 7a, the cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com