Fodder moisture detection control system

A detection and control system, moisture technology, applied in the direction of drying solid materials, lighting and heating equipment, drying, etc., can solve the problems such as the inability to automatically control the moisture content of the feed, and the error of measuring the moisture content of the feed, so as to improve efficiency and realize automatic operation , High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

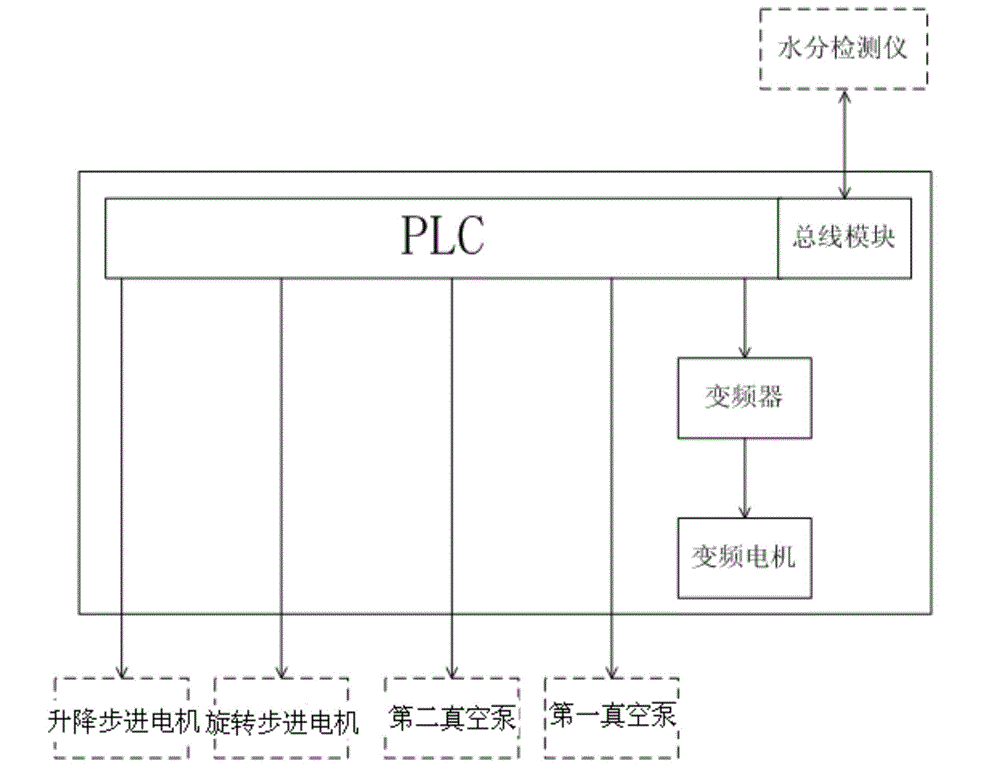

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

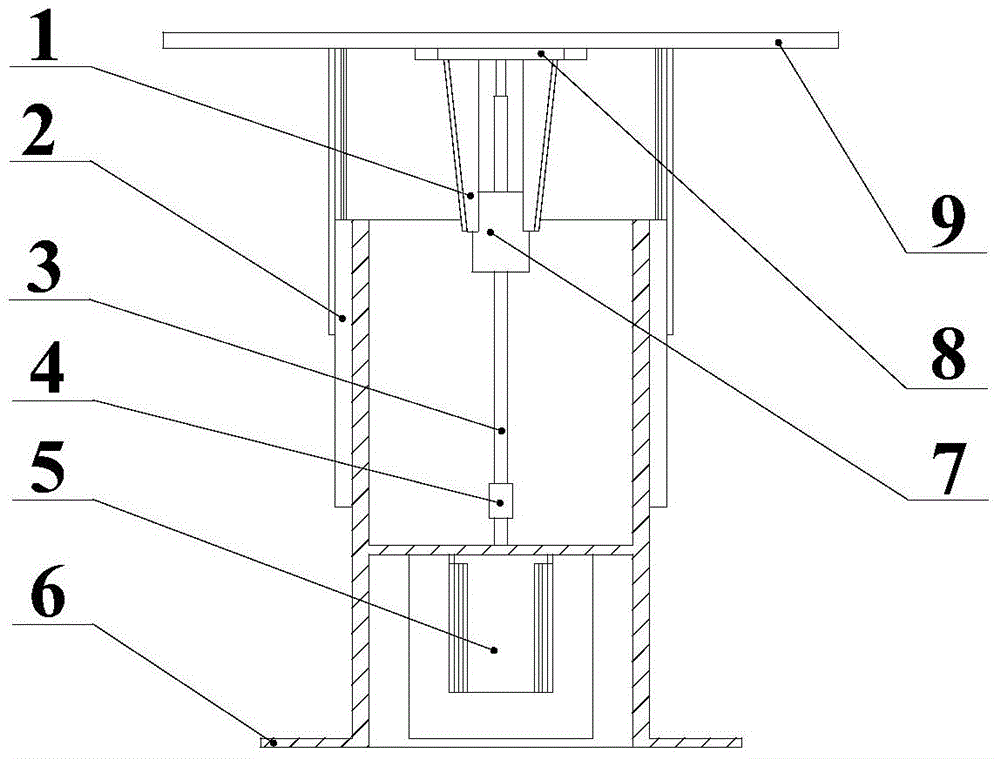

[0028] Feed moisture detection and control system, including a base 6, a lifting mechanism, a rotating mechanism, a moisture detector 19 and a waste bucket 22;

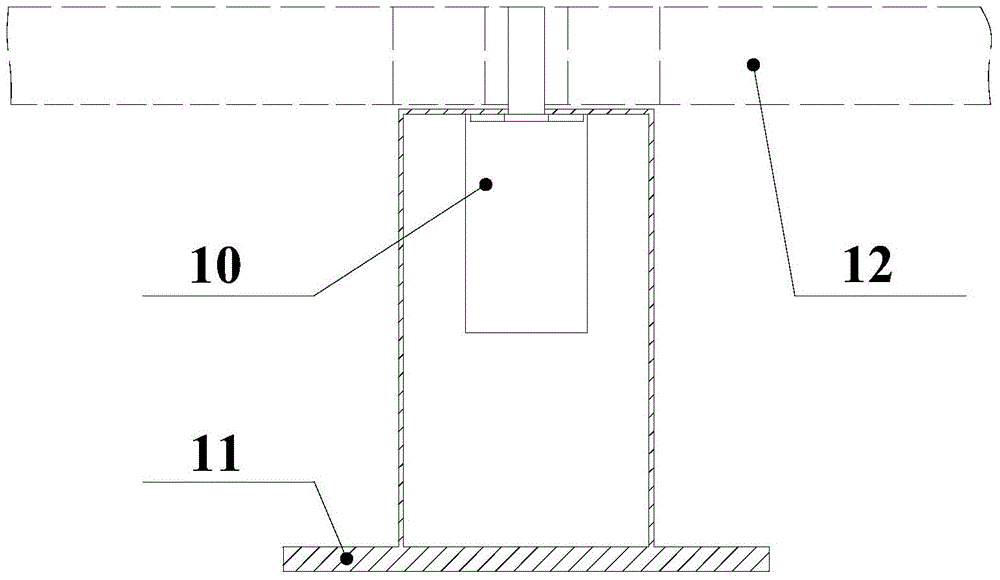

[0029] The lifting mechanism includes a lifting driver fixed on the base 6; the rotating mechanism includes a rotating driver 10 and a rotating frame 12; the rotating driver 10 is fixed on the support platform 9, and the output end of the supporting platform 9 and the lifting driver is fixed; The frame 12 is provided with a suction pipe, one end of the suction pipe is provided with a suction tray, and the other end is provided with a discharge tray, the discharge tray communicates with the vacuum pump through a vacuum tube, and a barrier to prevent feed from entering the vacuum tube is provided between the vacuum tube and the discharge tray. Isolation net 26;

[0030] When the rotating frame 12 is in the first working position, the feed reaches the moisture detector 19 from the feed conveyor belt 17 through the suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com