Ball friction type mechanical clutch

A mechanical clutch, friction type technology, applied in the field of clutch, can solve the problems of large friction loss, large external size, the inability of the driving shaft and the driven shaft to rotate synchronously, etc., to achieve large transmission torque, simple and economical manufacturing, and easy replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

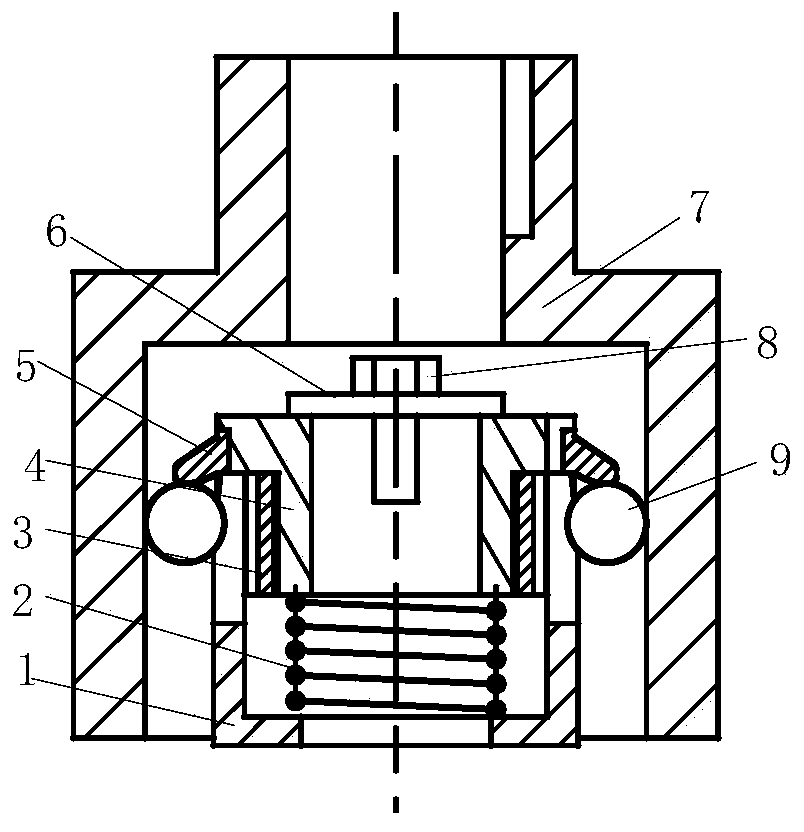

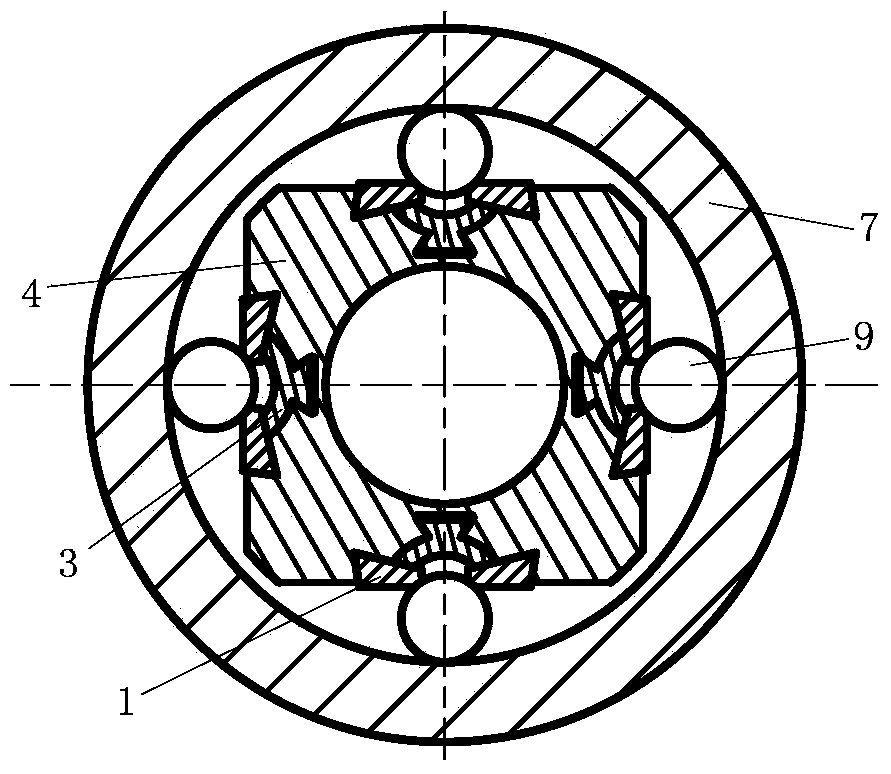

[0029] combine Figure 1-Figure 6 , the ball friction clutch of the present invention is made of ball friction clutch by outer casing 7, inner frame assembly, shift fork 1, ball 9, return spring 3, and wherein inner frame assembly is made of inner frame 4, ball baffle plate 5, strong magnet 3. Backing plate 6 and self-locking bolt 8 are formed. Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0030] There are dovetail-shaped slots on the inner frame 4 ( image 3 ), combined with figure 1 , The ball baffle 5 and the strong magnet 3 are directly embedded on the inner frame 4 through the dovetail seat. Pass the shaft through the 4 shaft holes of the inner frame, connect the inner frame assembly and the driven shaft through the flat key, the backing plate 6 and the self-locking bolt 8, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com