Piston swing cylinder hydraulic motor

A technology of hydraulic motor and plunger, applied in the field of plunger type swing cylinder hydraulic motor, can solve the problems of large contact stress, unstable tilting force and large lateral force of the working part, so as to improve the mechanical efficiency and volumetric efficiency, ensure the Low-speed performance to ensure stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

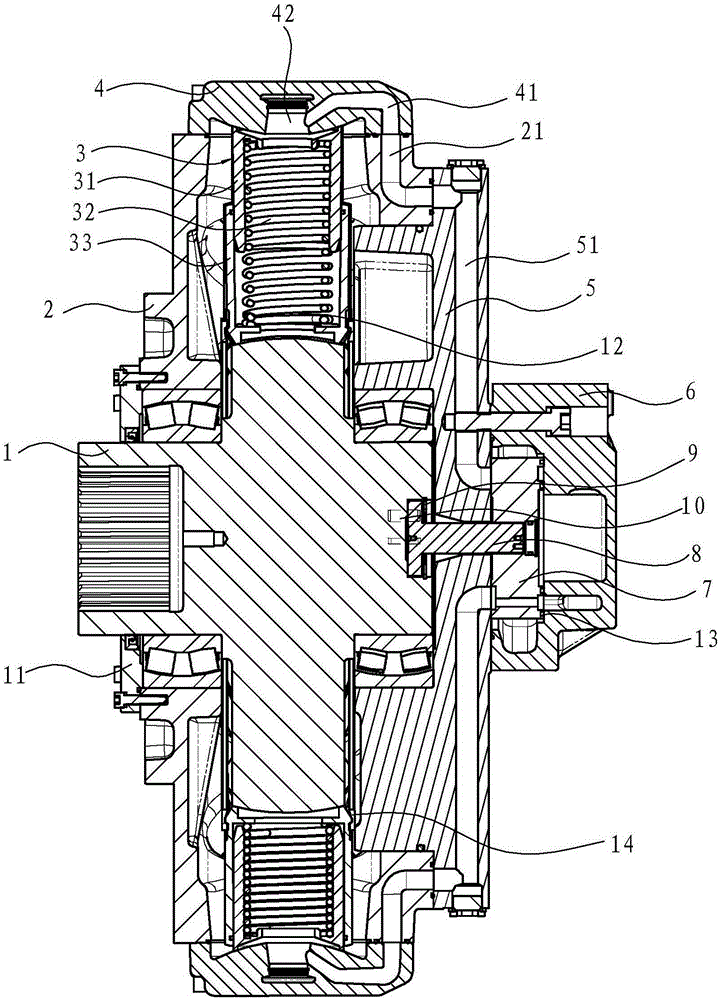

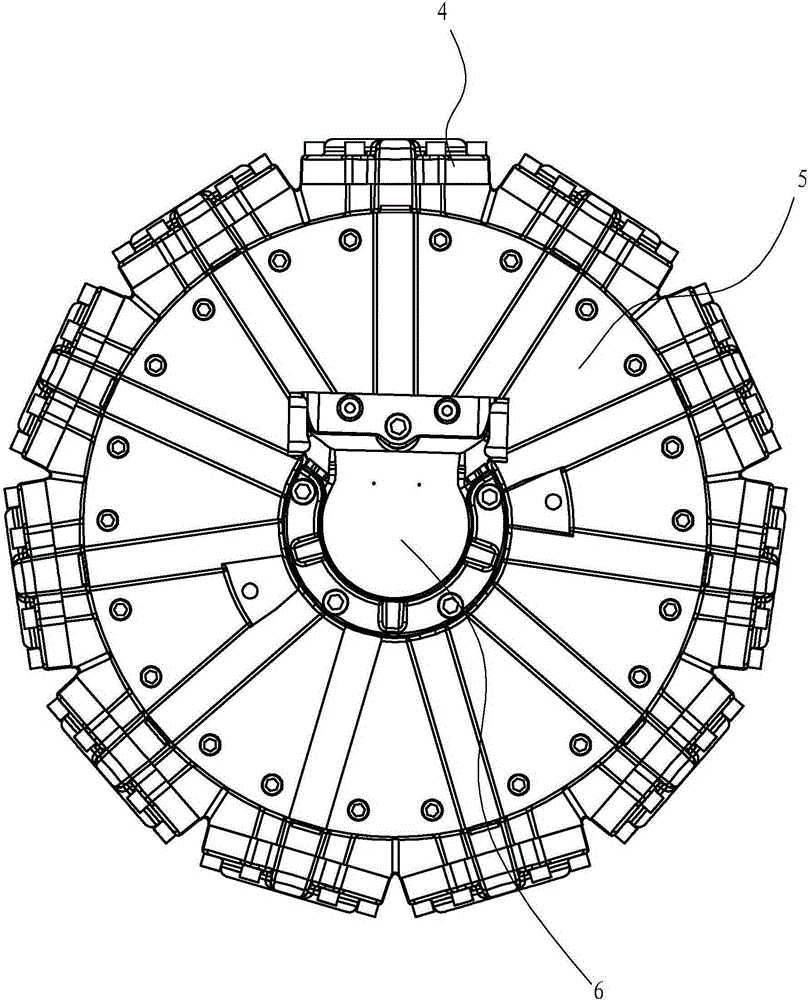

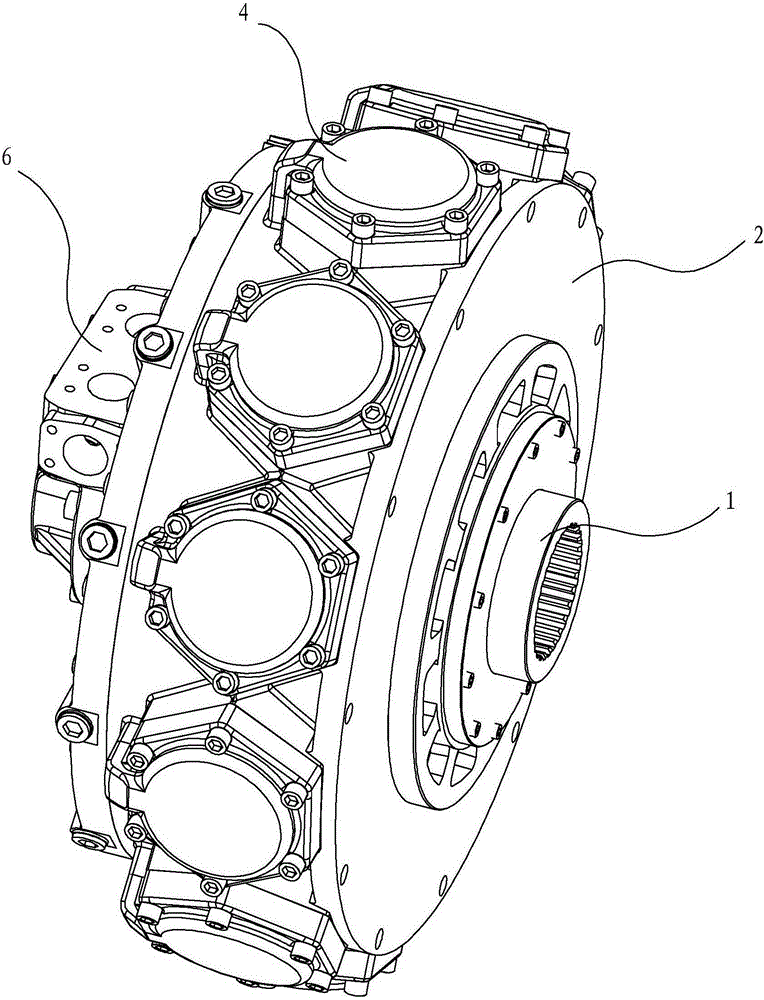

[0029] Such as Figure 1-14 As shown, the plunger swing cylinder hydraulic motor of the present invention includes a casing composed of a casing 2 and a front end cover 11 and a rear end cover 5 arranged on the front end surface and the rear end surface of the casing 2, and is arranged on the peripheral surface of the casing. The upper cylinder head 4, the eccentric shaft 1 supported in the casing by a set of bearings, and the oil distribution mechanism arranged on the rear end cover 5 are arranged radially along the radial direction of the eccentric shaft 1 in the casing. One above-mentioned cylinder cover 4, each cylinder cover 4 is provided with a piston-cylinder assembly 3, and each piston-cylinder assembly 3 includes a hollow piston 31 sliding in the inner cavity of the hollow oil cylinder 33 and a piston placed in the inner cavity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com