Retaining and protecting structure of reinforcing existing line of steel-structure self-drilling type hollow anchor rod

A protective structure, self-drilling technology, applied in basic structure engineering, sheet pile wall, excavation and other directions, can solve the problems of large amount of concrete, narrow construction site, unsuitable economy, etc. The effect of low site requirements and compact and lightweight equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] (1) Geological survey

[0038] Through on-site geological surveying and mapping, collection of existing design data and prospecting, the engineering geology and hydrogeological conditions of existing line retaining walls and retaining walls are ascertained, as well as existing reinforcement types, structural dimensions, and deformation and failure characteristics.

[0039] (2) Reinforcement design

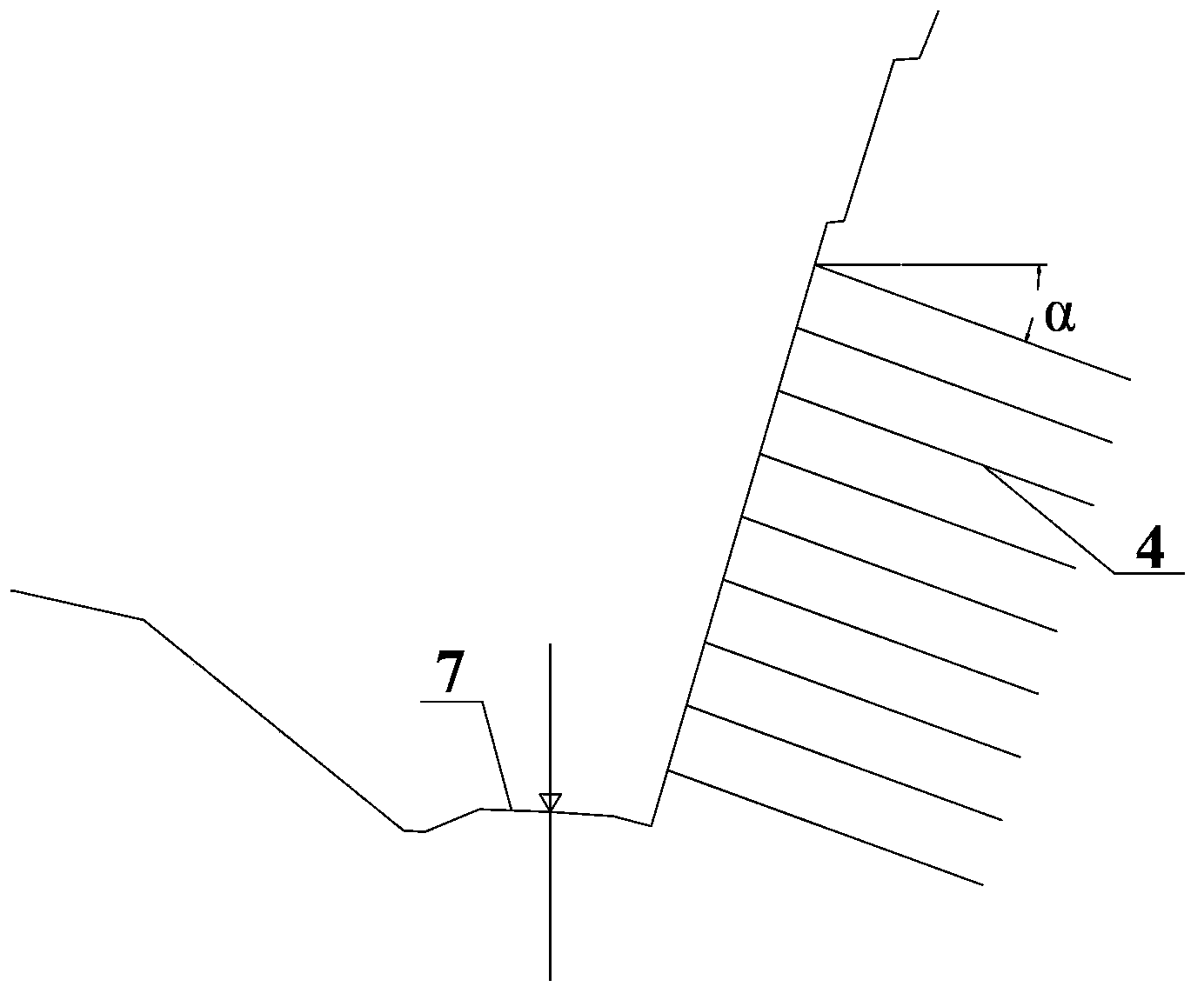

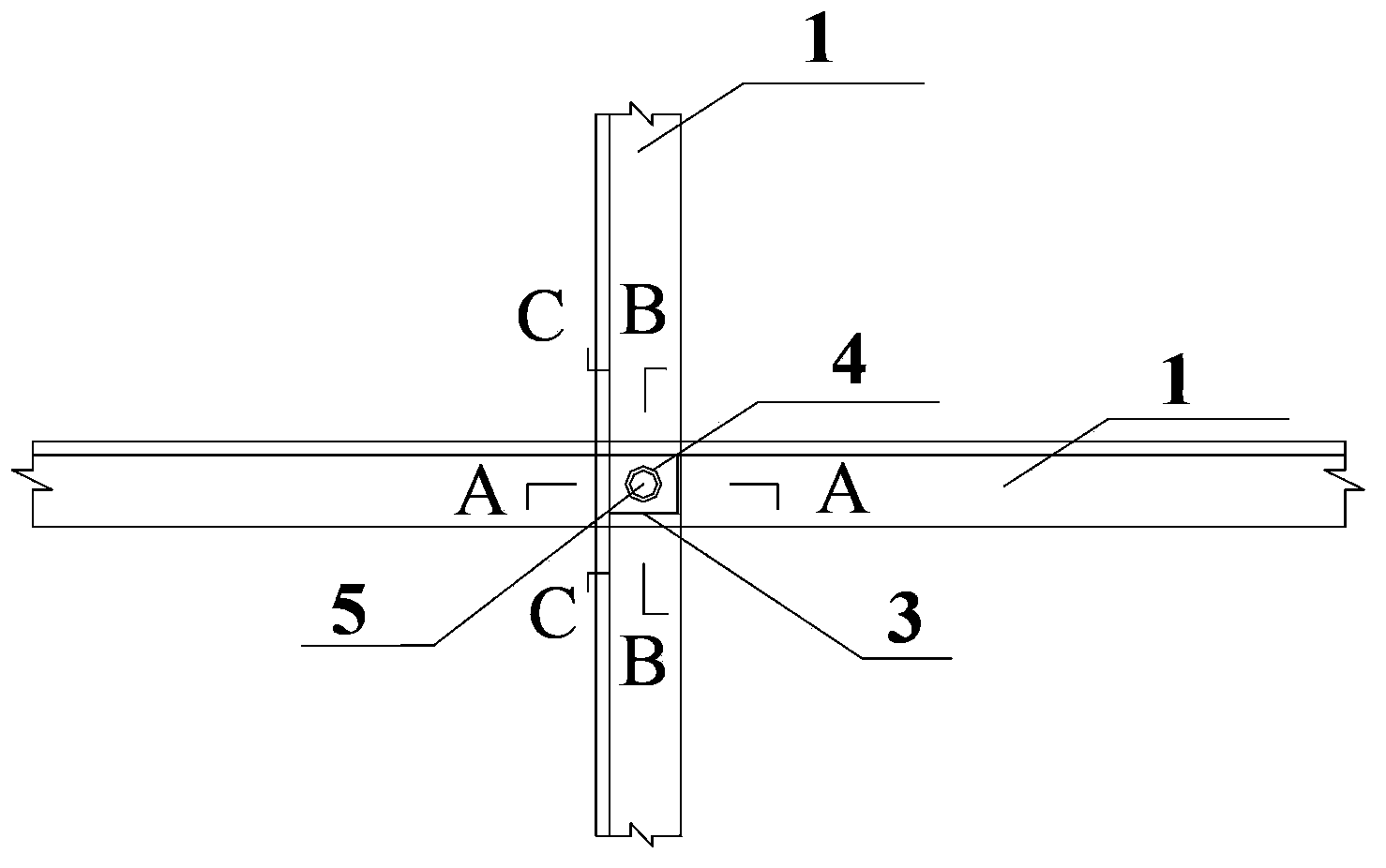

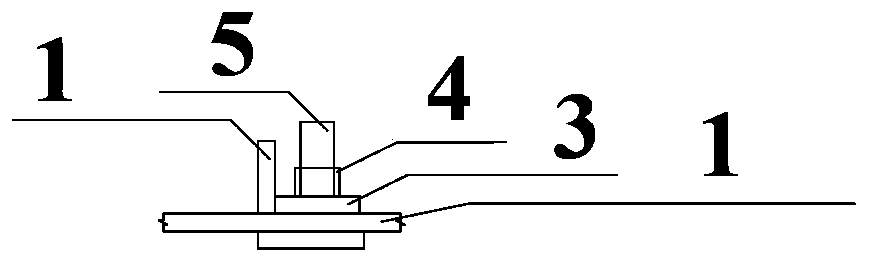

[0040] Combining with the measured section, through checking and calculation, determine the spacing and length of the self-drilling bolts, and determine the section size of the angle steel. The angle steel adopts 10cm*10cm*16mm angle steel. The length of each angle steel should be 6m, and welded connection is adopted; the anchor rod adopts a hollow bolt with an outer diameter of 32mm, the diameter of the anchor hole is 50mm, and the prestress is 120KN. The entry into the strongly weathered rock is no less than 6m. The self-drilling hollow anchor rod has an angle of 20° with the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com