Method for producing bean pulp feed additive

A feed additive and production method technology, applied in animal feed, animal feed, food science and other directions, can solve problems such as adverse effects, disturb the digestive tract, and unstable product quality, and achieve the effect of increasing protein content and small peptide content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

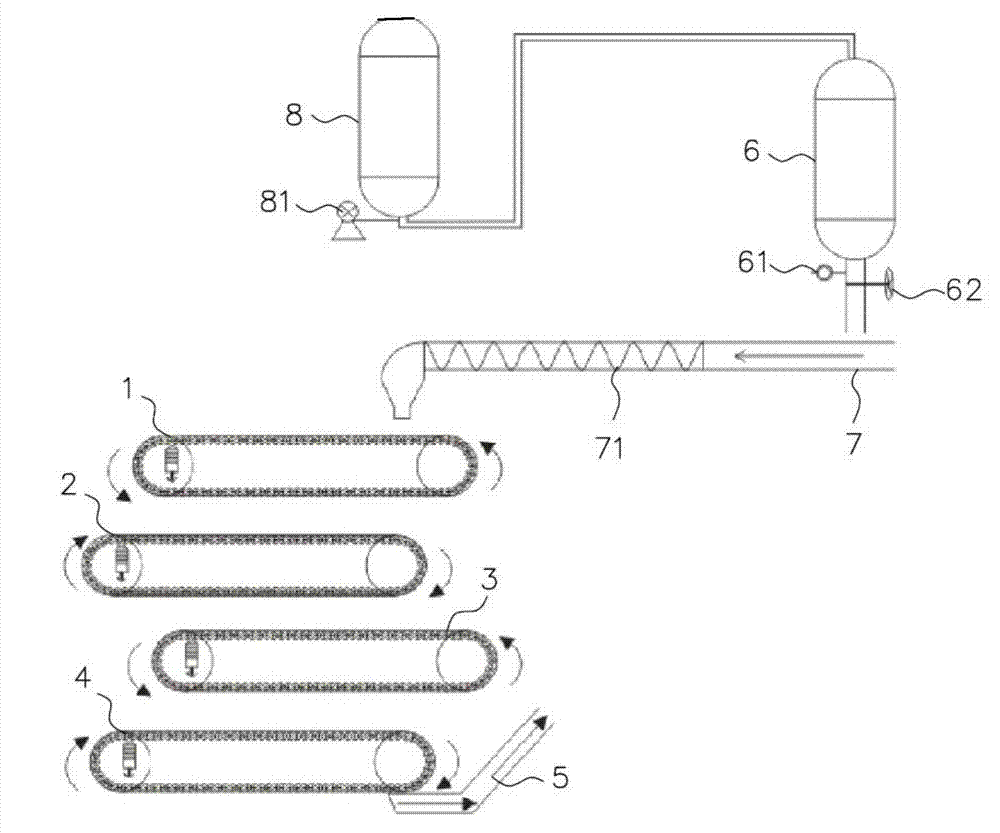

Method used

Image

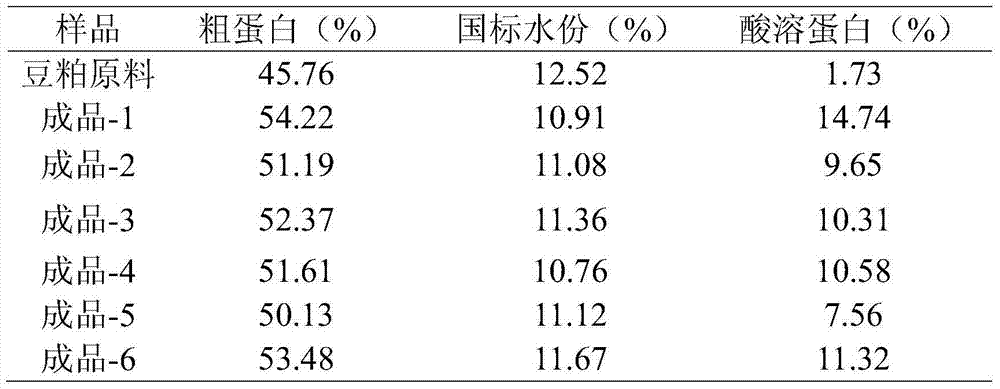

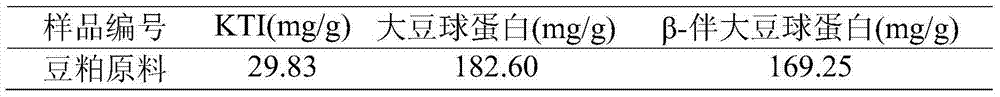

Examples

Embodiment 1

[0034] The specific implementation mode is a kind of production method of soybean meal feed additive, comprising:

[0035] (1) After activation of Bacillus subtilis CGMCC No.7690 on a slant, scrape a small amount into the nutrient broth basal medium (peptone 10g, beef extract 3g, sodium chloride 5g, water 1000mL, pH7.0, 121 ℃ high pressure Sterilize for 20 minutes; cool for standby), place at 37°C, shake at 200r / min for 24 hours, and prepare 3L seed solution; count the bacteria content on a blood cell counting board to ensure that the bacteria content reaches 10 10 CFU / mL;

[0036] (2) Put 3L seed solution into a fermenter containing 30L liquid fermentation medium (20g / L peptone, 6g / L beef extract, 10g / L sodium chloride, 20g / L glucose, sterilized by high temperature and high pressure in the fermenter) Carry out a first-stage expansion fermentation in the medium, control the temperature in the tank at 37°C, the ventilation rate is 5-8L / min, and the pH is 6.5-7.5. After 24 hour...

Embodiment 2

[0044] Fermentation was carried out using the same method and equipment as in Example 1, but no glucose was added in the solid state fermentation, thereby obtaining a soybean meal feed additive.

Embodiment 3

[0046] Utilize the same method and equipment as in Example 1 to ferment, the addition of glucose in the liquid fermentation medium is 40g / L, and the concentration of glucose in the material obtained after each component is mixed during solid fermentation is 20g / L. L, thereby obtaining the soybean meal feed additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com