Gyratory crusher with piston

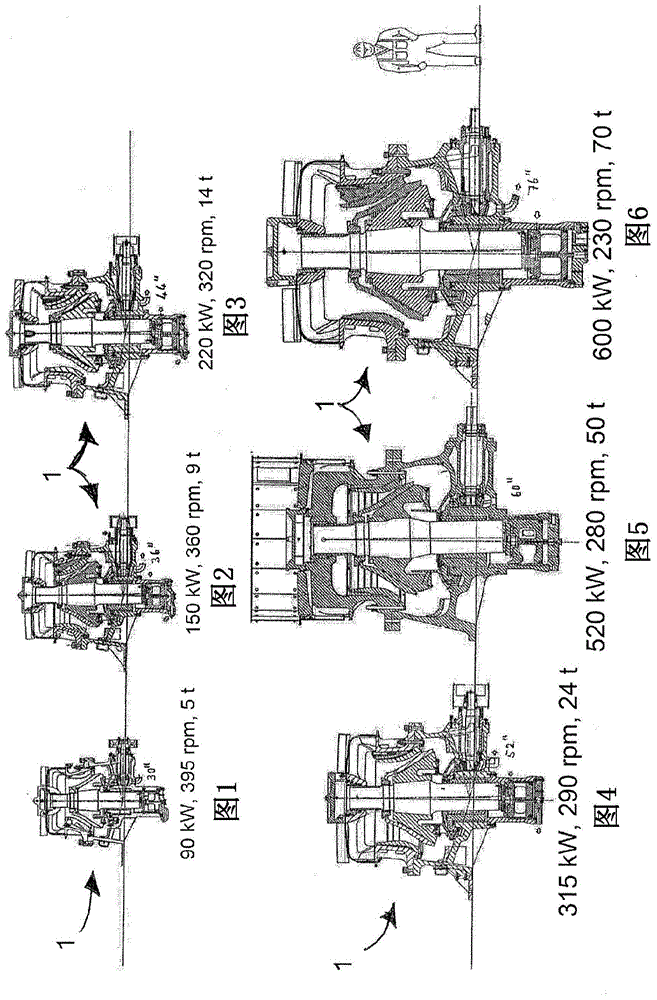

A gyratory crusher, piston technology, applied in grain processing and other directions, can solve problems such as piston cracking, fracture, piston deformation, etc., to achieve the effect of increasing the crushing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

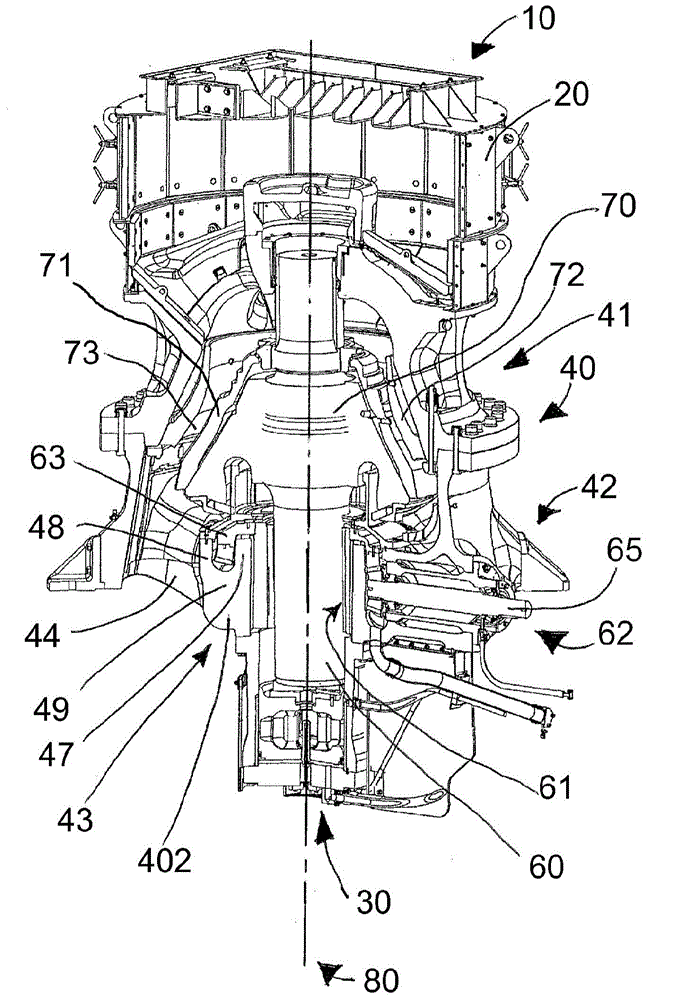

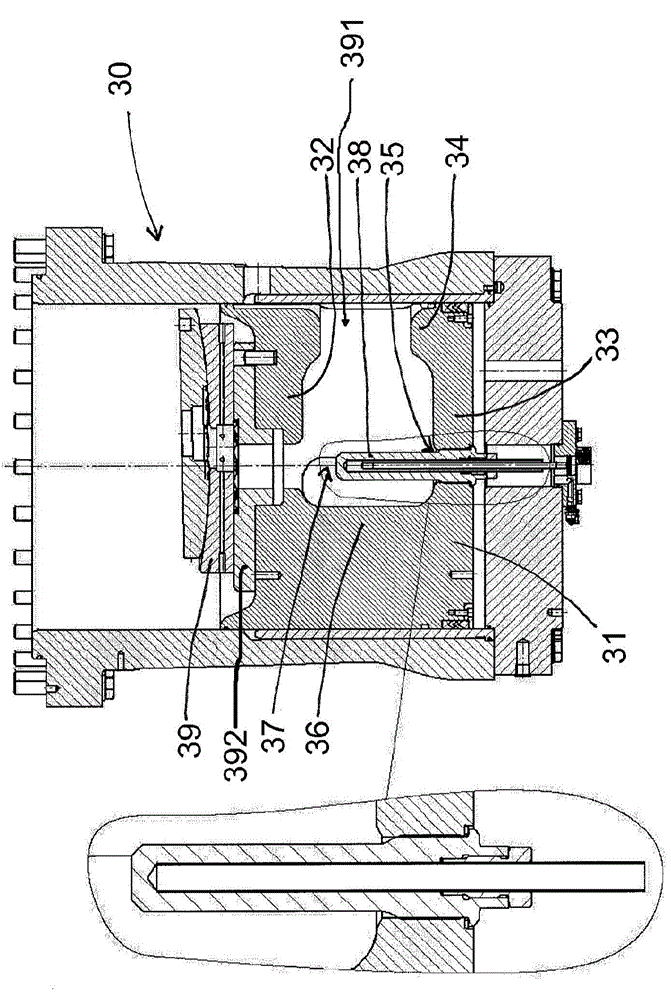

[0039] will now refer to Figure 7-12 Describe the piston and crusher. Crusher 10 ( Figure 7 ) has a frame 40 comprising an upper frame portion 41 and a lower frame portion 42 comprising a hub 43 . The vertical central axis 60 is via a spherical support in the cylinder-piston assembly 30 (see Figure 7-10 ) and supported by the lower frame portion 42 of the frame 40, the cylinder-piston assembly 30 includes thrust bearings 39 (see Figure 7-12 ), the thrust bearing 39 is arranged on the piston 31 arranged in the hydraulic cylinder arranged in the frame 40 . The eccentric 61 is rotatably arranged around the central axis 60, ie mounted on the shaft, about which the eccentric is adapted to rotate. The crushing head 70 is mounted around the central axis and thus indirectly in the eccentric 61 . The drive shaft is arranged to rotate the eccentric 61 about the central axis 60 by means of a conical gear meshing with a ring gear connected to the eccentric. The eccentric compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com