Dynamic grading method for leakage risk of liquid chemical pipelines in petrochemical wharf

A petrochemical and pipeline leakage technology, applied in the field of petrochemical terminal risk management, can solve problems such as poor objectivity and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further explanation will be given below by taking the implementation of the method for dynamically grading the risk of leakage of liquid chemical pipelines in a petrochemical wharf as an example in a certain wharf.

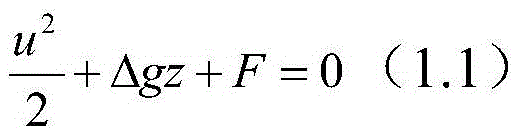

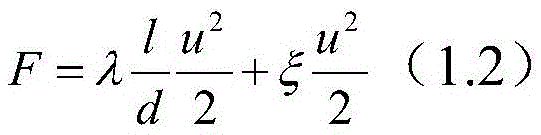

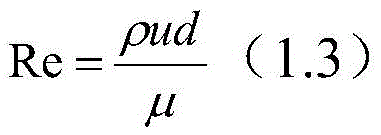

[0016] In the technical scheme of the method for dynamically grading the leakage risk of liquid chemical pipelines in petrochemical wharfs according to the present invention, the step (1) determines the type of leakage source according to the size of the leakage hole of the pipeline, and the type of leakage source is divided into liquid nozzle leakage and liquid pipeline leakage. Small hole leaks. The method of determining the two forms of leakage sources is to distinguish according to the size of the leakage aperture. Due to external impact, collision or equipment corrosion and wear, there are cracks or holes on the pipeline, and the size is generally less than 20mm, which is the small hole leakage of the liquid pipeline; when the pipeline bursts, breaks o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com