Vibration isolation structure of plate heat exchanger of equipment layer air conditioning system

A technology for plate heat exchangers and air conditioning systems, applied in lighting and heating equipment, space heating and ventilation details, household heating, etc. In place and other issues, to achieve the effect of high vibration isolation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

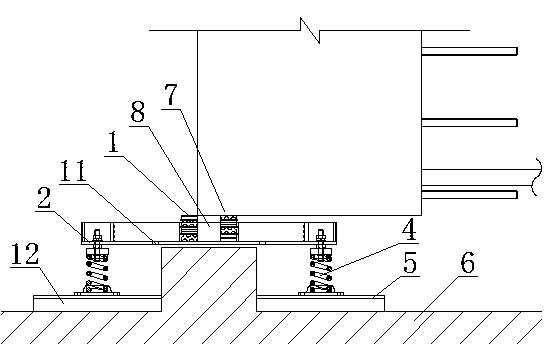

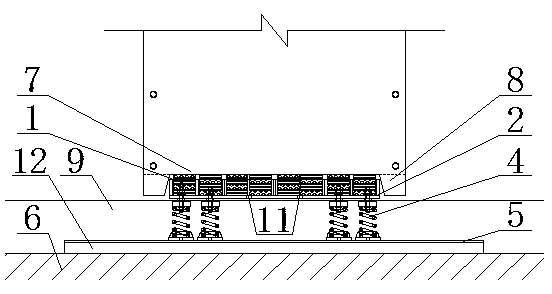

[0015] exist figure 1 , 2 , In the embodiment shown in 3, the vibration isolation structure of the main body of the plate heat exchanger consists of a rubber vibration isolation pad (1), a supporting steel structure (2), a rigid mass (3), an adjustable spring vibration isolator (4), The galvanized supporting steel plate (5) is arranged between the main body of the plate heat exchanger and the floor (1); the supporting steel structure (2) is installed on the base of the plate heat exchanger (7), the lower steel beam of the plate heat exchanger ( 8) Between the ground beam (9), one side is under the main body of the plate heat exchanger, and the other side is outside the main body of the plate heat exchanger; the supporting steel structure (2) is an integrated steel plate made of galvanized steel plate (10) structure, rubber vibration isolation pads (1) and rigid mass blocks (3) are set on the top, drain holes (11) are set in the supporting steel structure (2), and the adjustab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com