Hidden frame dense rib cavity floor

A cavity floor and dense rib technology, applied in the direction of floor slabs, building components, insulation, etc., can solve the problems of cost increase, affecting the appearance of the floor, cumbersome construction, etc., to achieve convenient construction, beautiful overall effect, and shorten the construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] In the following, the technical solutions of the present invention will be further described in detail through embodiments and in conjunction with the drawings. Obviously, the described embodiments are only part of the embodiments of the present invention.

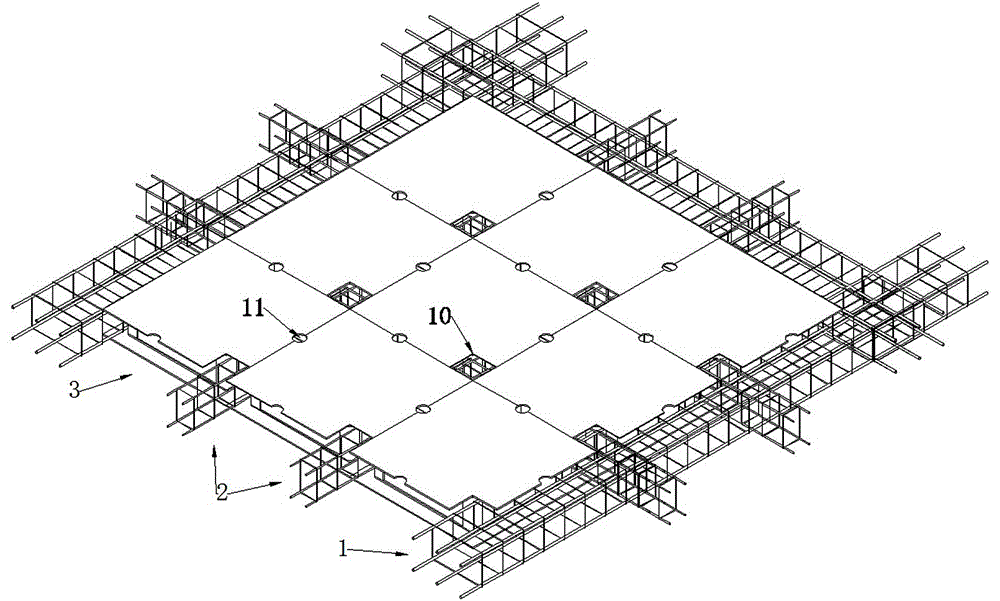

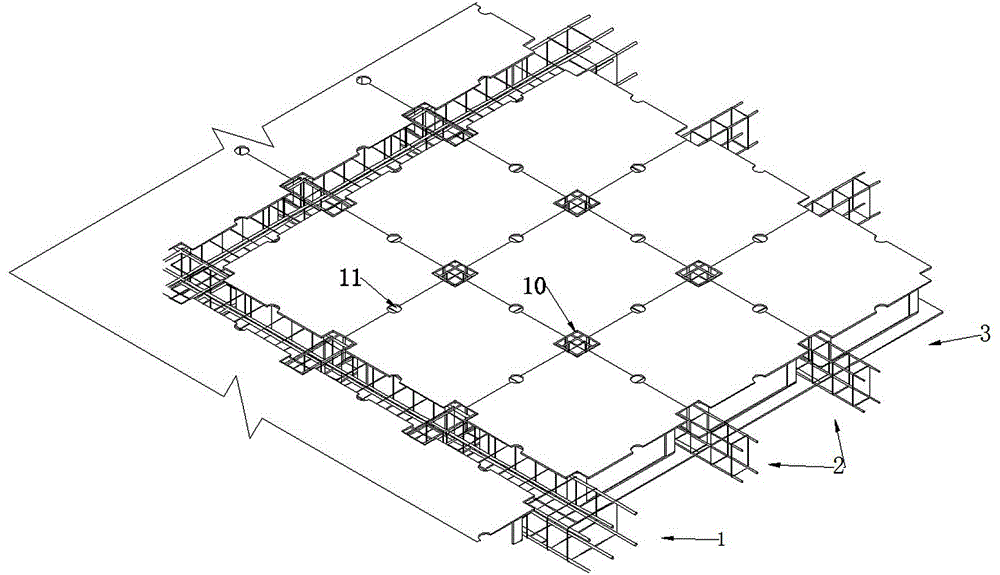

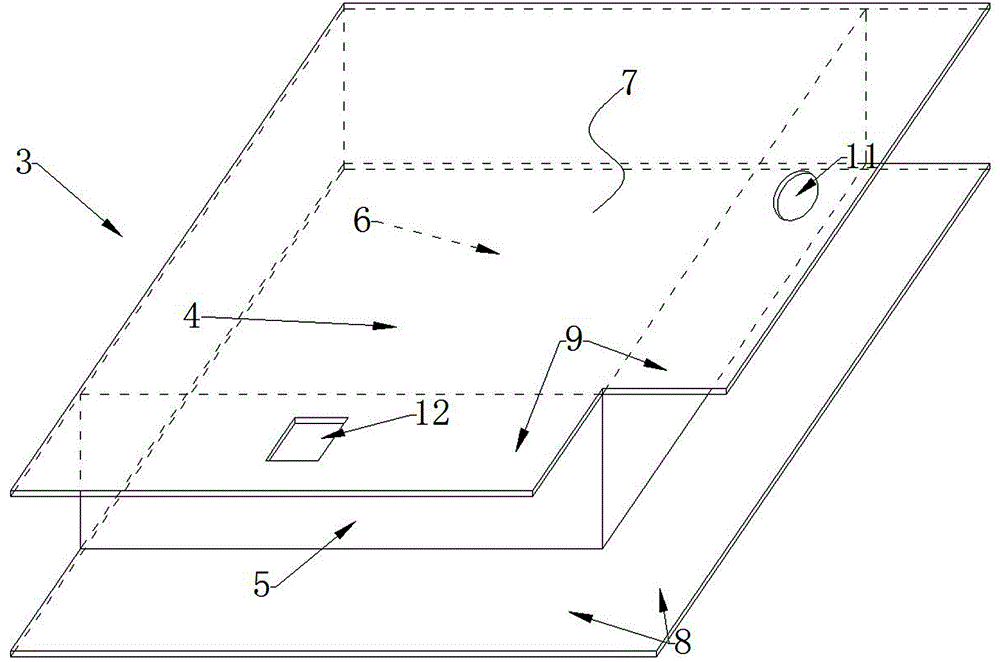

[0030] A hidden-frame multi-ribbed cavity floor slab. Firstly, wire is laid on the supported formwork to position the frame beam 1, the multi-ribbed beam 2 and the prefabricated cavity member 3, such as figure 1 As shown, the prefabricated cavity member 3 is made of material made of concrete or glass magnesium board, and the prefabricated cavity member 3 is jointly enclosed by the upper plate 4, the surrounding side walls 5 and the lower plate 6 to form a cavity Body 7, the lower board 6 has at least two adjacent side edges with underhanging edges 8 protruding outwards, and the two adjacent underhanging edges 8 extend outward in the direction of the lower board 6 and mutually The upper board 4 has at least two adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com