Novel working device and excavator

A technology for working devices and excavators, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of small-scale operation working device working range limitation, working range limitation, damage to the boom cylinder, etc., to improve the recovery angle and The effect of increasing the range, working range, and increasing the rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

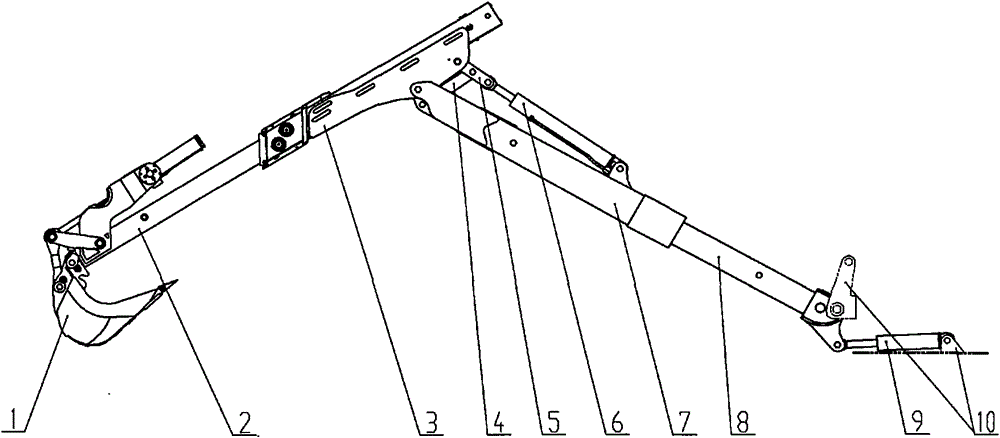

[0028] see figure 1 and figure 2 , a new type of working device, including: work tool terminal 1, telescopic stick 2, stick sleeve 3, stick rocker 4, stick connecting rod 5, stick cylinder 6, boom sleeve 7, telescopic stick Boom 8, boom cylinder 9 and platform ear plate 10: the rod sleeve 3 contains the stick telescopic cylinder, and the boom sleeve 7 contains the boom telescopic cylinder; the rear hinge point of the boom cylinder 9 is hinged with the internal ear plate 10 of the platform, The front hinge point is hinged with the lower hinge point of the telescopic boom 8, and the upper hinge point of the telescopic boom 8 is hinged with the platform ear plate 10, which is used to connect the body of the excavator; the boom sleeve 7 and the telescopic boom 8 are stretched through the boom The oil cylinder realizes relative translational movement, the rear hinge point of the boom sleeve 7 is hinged with the rear hinge point of the arm cylinder 6, the upper hinge point of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com