Production process for large-section aluminum alloy radiating fin

A technology of aluminum alloy and heat sink, applied in the field of aluminum alloy manufacturing, can solve the problem that it is difficult to meet the dimensional tolerance and surface quality of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

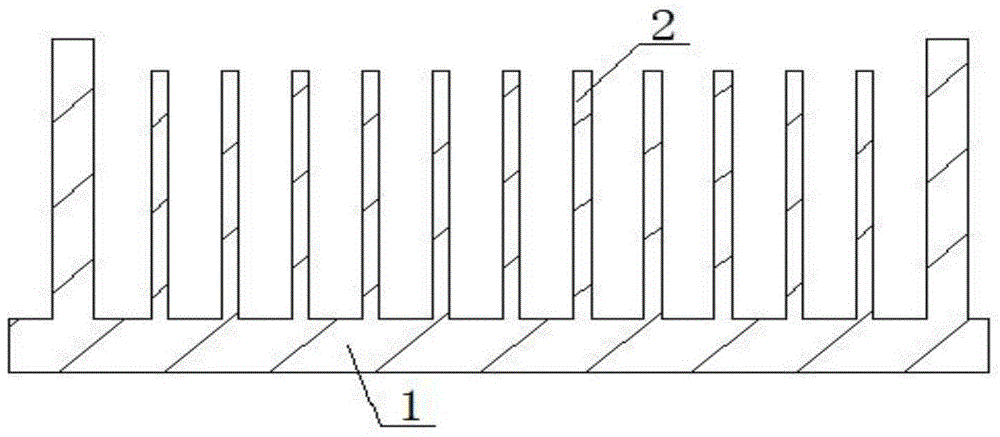

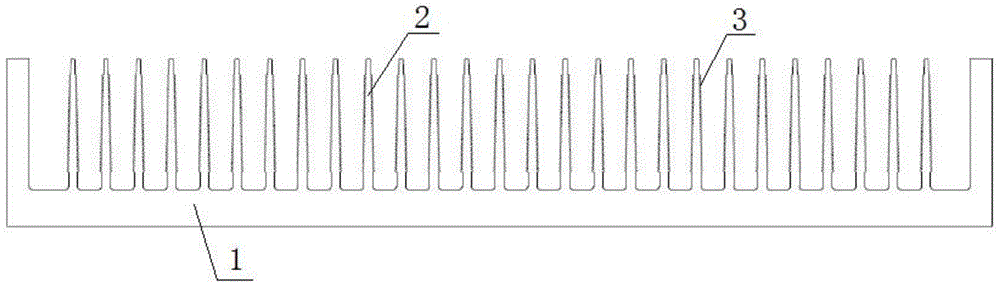

Image

Examples

Embodiment 1

[0018] The process for producing large-section aluminum alloy heat sinks in this embodiment includes the steps of composition optimization, casting billet making, extrusion molding, quenching, stretching and straightening, and aging treatment in sequence. After the composition optimization step, the composition and quality of the aluminum alloy are optimized. For example: Si: 0.30%, Fe: 0.22%, Cu: 0.03%, Mn: 0.05%, Mg: 0.48%, Cr: 0.05%, Zn: 0.03%, Ti: 0.06%, Al: balance; In the extrusion molding step, the extrusion speed is 0.8m / min, the casting rod temperature is 525°C during extrusion molding, the temperature difference between the front and rear ends of the casting rod is 25°C, the mold temperature is 485°C, and the extrusion cylinder temperature is 465°C.

[0019] As an improvement of this embodiment, the profile obtained in the extrusion molding step is quenched immediately after being released from the mold, and the quenching method is air cooling.

[0020] As an improve...

Embodiment 2

[0023] The process for producing large-section aluminum alloy heat sinks in this embodiment includes the steps of composition optimization, casting billet making, extrusion molding, quenching, stretching and straightening, and aging treatment in sequence. After the composition optimization step, the composition and quality of the aluminum alloy are optimized. For example: Si: 0.40%, Fe: 0.18%, Cu: 0.05%, Mn: 0.03%, Mg: 0.58%, Cr: 0.03%, Zn: 0.05%, Ti: 0.04%, Al: balance; In the extrusion molding step, the extrusion speed is 1.8m / min, the casting rod temperature is 495°C during extrusion molding, the temperature difference between the front and rear ends of the casting rod is 35°C, the mold temperature is 515°C, and the extrusion cylinder temperature is 435°C.

[0024] As an improvement of this embodiment, the profile obtained in the extrusion molding step is quenched immediately after being released from the mold, and the quenching method is air cooling.

[0025] As an improve...

Embodiment 3

[0028] The process for producing large-section aluminum alloy heat sinks in this embodiment includes the steps of composition optimization, casting billet making, extrusion molding, quenching, stretching and straightening, and aging treatment in sequence. After the composition optimization step, the composition and quality of the aluminum alloy are optimized. For example: Si: 0.35%, Fe: 0.20%, Cu: 0.04%, Mn: 0.04%, Mg: 0.52%, Cr: 0.04%, Zn: 0.04%, Ti: 0.05%, Al: balance; In the extrusion molding step, the extrusion speed is 0.8-1.8m / min, the casting rod temperature is 510°C during extrusion molding, the temperature difference between the front and rear ends of the casting rod is 30°C, the mold temperature is 500°C, and the extrusion barrel temperature is 450°C .

[0029] As an improvement of this embodiment, the profile obtained in the extrusion molding step is quenched immediately after being released from the mold, and the quenching method is air cooling.

[0030] As an imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com