Single-phase CaFe2O4 micro-nano hierarchy material with surface texture and preparation method thereof

A technology of hierarchical structure and surface texture, which is applied in the field of material chemistry, can solve the problems of singleness of materials, etc., and achieve the effects of simple operation, rich material fields, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] (1) Mix 2 moles of calcium oxalate and 4 moles of iron ammonium oxalate crystals, add a mixed solvent of 10 mL deionized water and 20 mL of anhydrous ethylene glycol, and stir for 2 hours with a magnetic stirrer.

[0013] (2) Add 1 gram of oxalic acid to the solution obtained in step (1), continue to stir for 0.5 hours, then transfer it to a stainless steel reaction kettle with a polytetrafluoroethylene substrate, conduct a hydrothermal reaction at 180°C for 14 hours, filter, and remove the precipitate After washing twice with distilled water, dry at room temperature to obtain single-phase CaFe with surface texture 2 o 4 Micro-nano hierarchical structure materials.

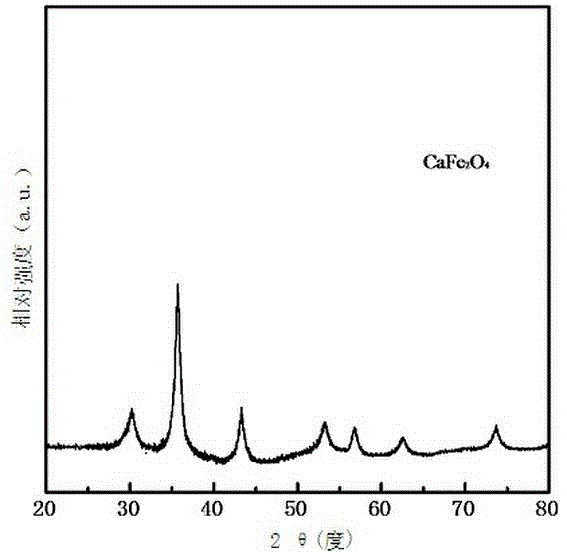

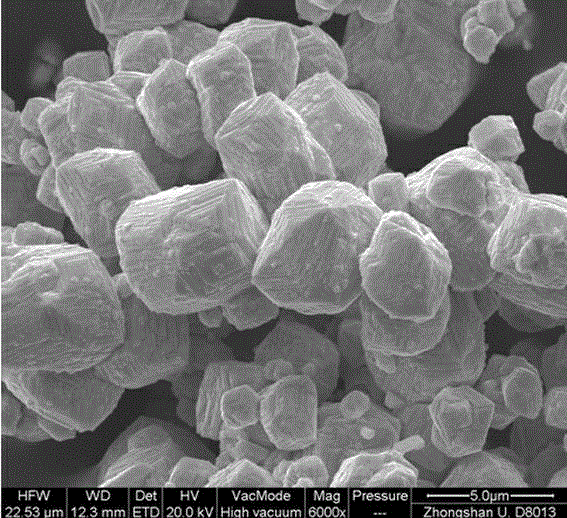

[0014] Single-phase CaFe with surface texture 2 o 4 The X-ray diffraction pattern of the micro-nano hierarchical structure material is shown in figure 1 , single-phase CaFe with surface texture 2 o 4 The field emission scanning diagram of the micro-nano hierarchical structure material is shown in fi...

Embodiment

[0016] (1) Mix 0.5 mol of calcium oxalate and 1 mol of iron ammonium oxalate crystals, add 8 mL of deionized water and 32 mL of anhydrous ethylene glycol mixed solvent, and stir for 3 hours with a magnetic stirrer.

[0017] (2) Add 3 grams of oxalic acid to the solution obtained in step (1), continue to stir for 1 hour, then transfer it to a stainless steel reaction kettle with a polytetrafluoroethylene substrate, conduct a hydrothermal reaction at 230°C for 24 hours, filter, and remove the precipitate After washing 3 times with distilled water, dry at room temperature to obtain the single-phase CaFe with surface texture 2 o 4 Micro-nano hierarchical structure materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com