High-capacity organic garbage lifting and oriented discharging system

An organic waste, large-capacity technology, applied in the direction of waste conveying, lifting device, waste collection, etc., can solve the problems of falling off, small conveying volume, easy shutdown, etc., to prolong the service life, facilitate unloading, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

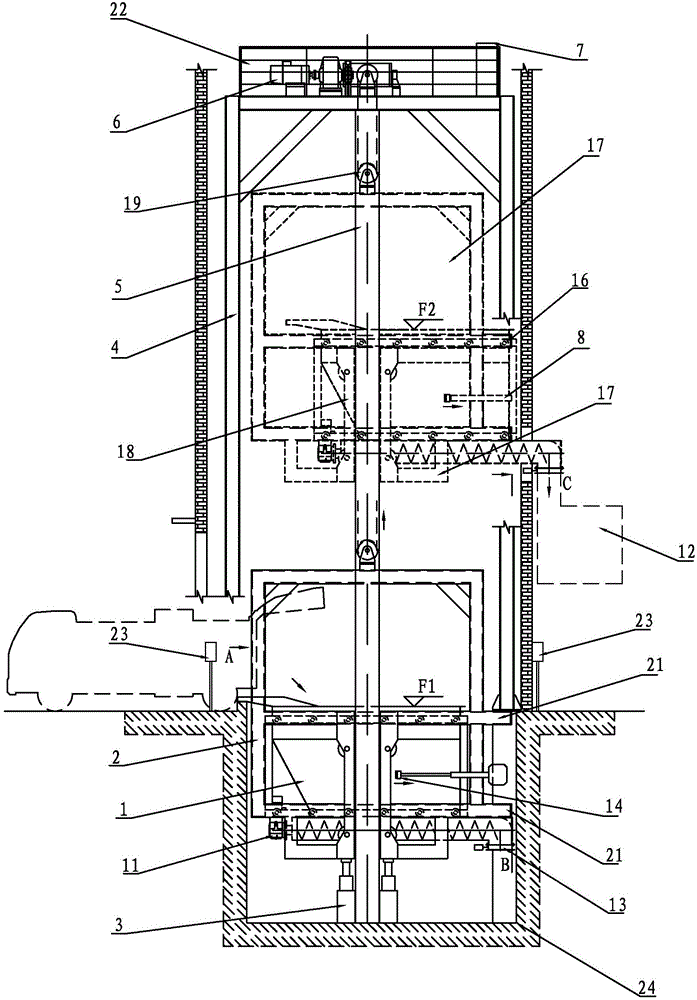

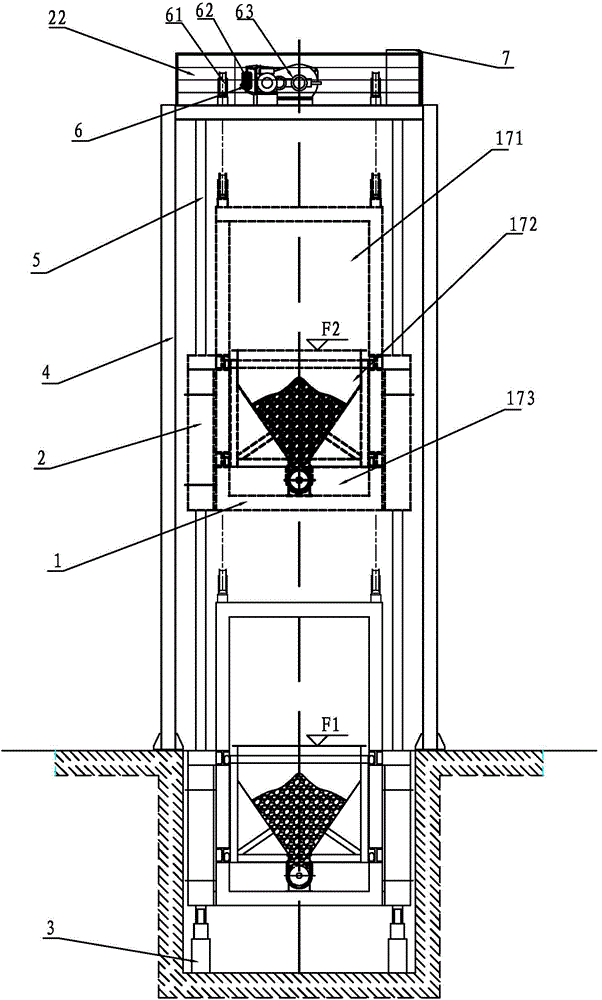

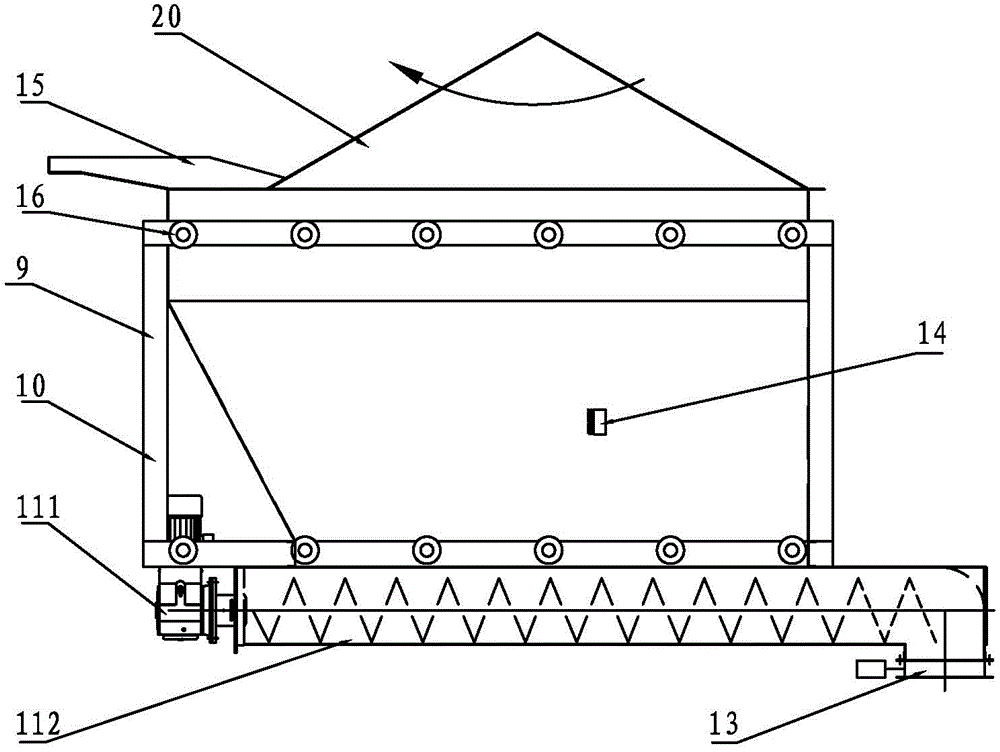

[0026] Such as figure 1 , figure 2 , Figure 5 , Figure 6 As shown, the large-capacity organic waste lifting and directional unloading system of the present invention includes a bin assembly 1 , a lifting frame assembly 2 , a main frame 4 and a vertical lifting mechanism 6 .

[0027] The large-capacity organic waste lifting and directional unloading system of the present invention is installed on the foundation, which is located below the ground and is a cubic pit 24 . Four buffer devices 3 are fixedly installed at the bottom of the pit 24. When the bin assembly 1 and the lifting frame assembly 2 are in the lower position, that is, the position when the garbage truck dumps garbage into the bin, the bin assembly 1 in line with the ground.

[0028] The bottom of the main frame 4 is fixedly installed on the edge of the pit 24, and the main frame 4 is located above the ground. The main frame 4 is a cubic frame formed by fixed connection of several crossbeams and longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com