Self-navigation full-automatic cleaning device for photovoltaic cell panel

A photovoltaic cell panel, fully automatic cleaning technology, applied in the direction of cleaning method using liquid, cleaning method using tools, cleaning method and utensils, etc., can solve the problem of difficulty in large-scale promotion and application, high equipment maintenance cost, high equipment cost problems, to achieve the effect of overcoming seasonal incompatibility, saving labor costs, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

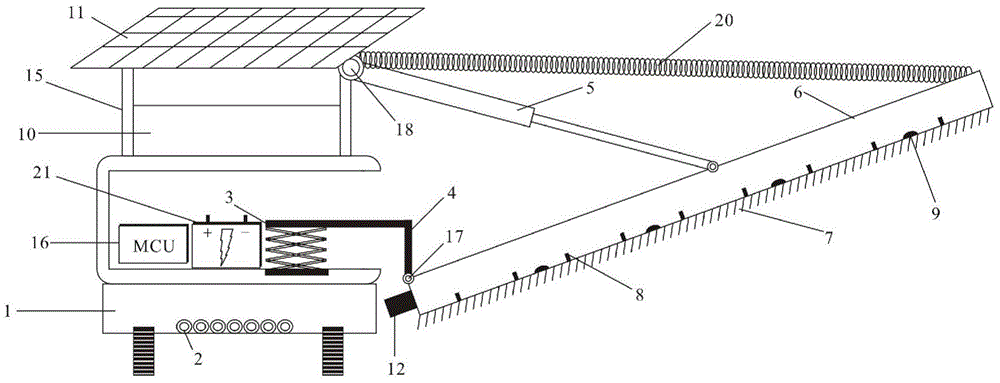

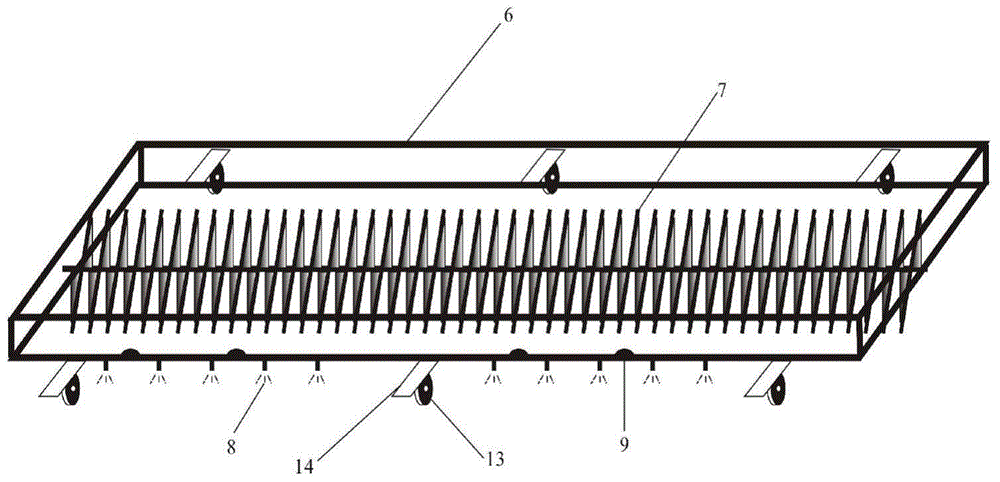

[0023] Such as figure 1 The self-navigating fully automatic cleaning device for photovoltaic panels includes a carrying car 1, a navigation sensor system 2, a brush roller bracket 6, an adjustment device for the brush roller bracket 6, a vehicle bracket 15, a main control system 16 and a power supply 21, A brush roller 7 and a brush roller driving motor 12 are arranged on the brush roller support 6 . Carrying trolley 1 has carried all above-mentioned equipments.

[0024] The adjusting device of the brush roller support 6 includes a lifting platform 3 and a telescopic rod 5 . The bottom of the lifting platform 3 is fixedly connected to the carrying trolley 1, and the top is connected to the brush roller bracket 6 through the L-shaped connecting steel plate 4, wherein the end of the brush roller bracket 6 close to the car body is connected to the L-shaped connecting steel plate 4 through the bearing A 17 . The brush roller bracket 6 rises or falls with the lifting platform 3 ...

Embodiment 2

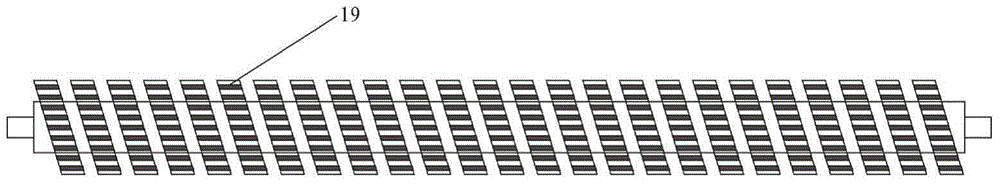

[0032] On the basis of Embodiment 1, a plurality of photoelectric sensor systems 9 and high-pressure nozzles 8 are installed on the bottom surface of the brush roller bracket 6, and a water tank 10 is installed on the vehicle-mounted bracket 15, and the water tank 10 and the high-pressure nozzle 8 are connected by a water pump and a pipeline to provide Rinse with water. The photoelectric sensing system 9 mainly consists of a miniature photoelectric camera and an array of photosensitive elements. The camera transmits the collected images to the main control system 16 in real time. The main control system 16 performs binary analysis on the images, uses conventional image processing technology, and calculates the degree of pollution (light pollution, medium pollution) according to the gray value standard set in advance. , heavy pollution three levels) for judgment. The photosensitive elements are scattered on both sides of the brush roller support 6, detect the reflected light i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com