Three element diaphragm damper for fuel pump

A high-pressure fuel pump and diaphragm technology, which is applied to the components, pump components, engine components, etc. of the pumping device for elastic fluids, and can solve the problems of inability to wind up, the diaphragm cannot work, and the pressure of the damper is too large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

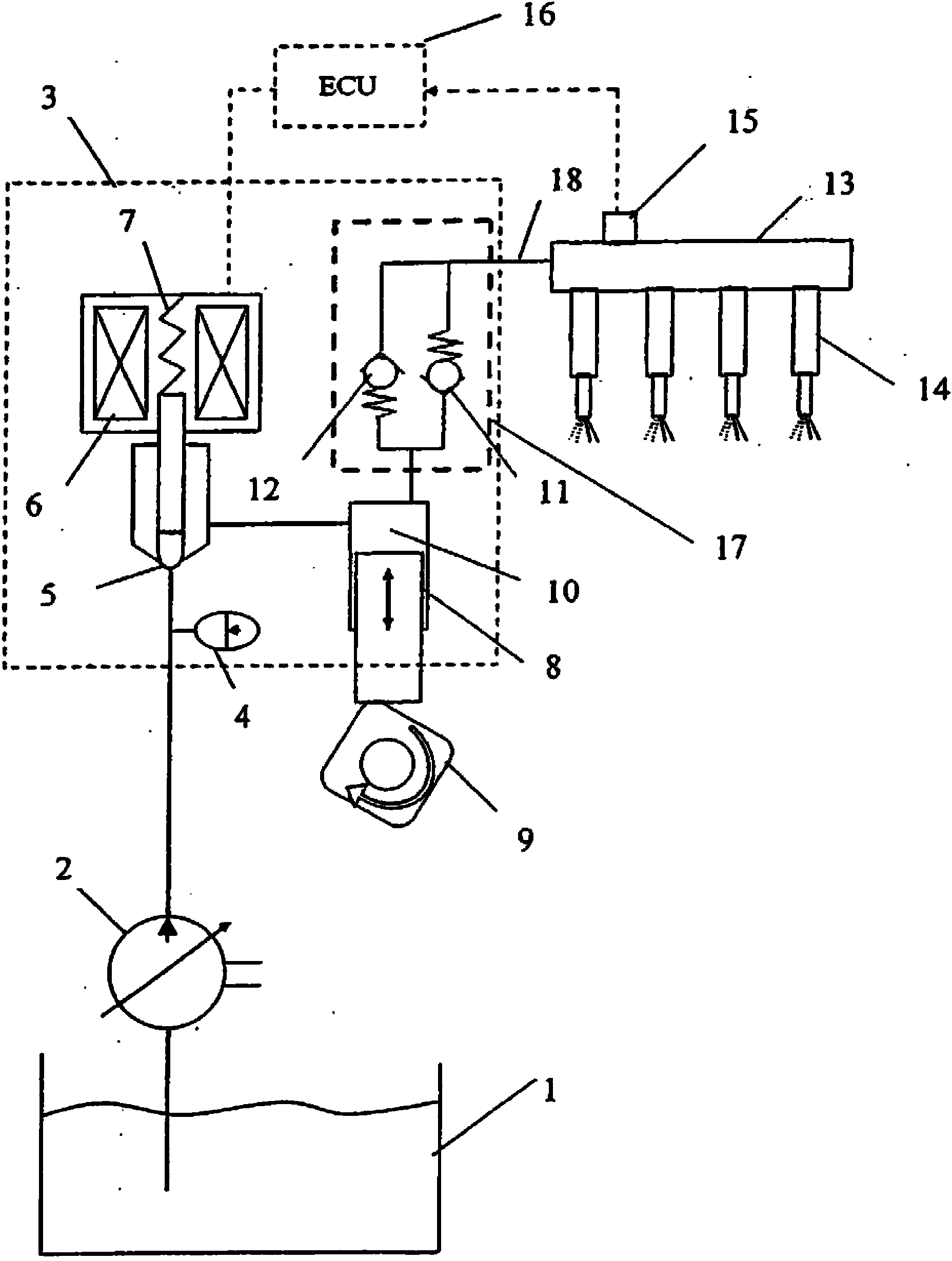

[0024] figure 1 is a schematic diagram illustrating the overall system of an internal combustion engine fuel system. The low pressure pump 2 pressurizes the fuel from the fuel tank 1 and delivers it to the high pressure pump housing 3 through the inlet connection. The fuel then passes through a pressure damper comprising a diaphragm assembly 4 and through a normally closed control valve 5 . In addition, a pressure damper can be located upstream of the pump housing 3 . A normally open control valve is also suitable for this fuel system. The fuel is then pumped into the pump chamber 10 where it is pressurized by the upward movement of the pump piston 8 via the engine camshaft 9 . The control valve 5 acts via a control valve spring 7 and a solenoid 6 to control the amount of fuel delivered by the high pressure pump. This is accomplished by precisely controlling the timing of closing the control valve relative to the upward travel position of the pump piston. When the fuel is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com