A kind of preparation method of laminated electrode

A technology of laminated electrodes and reflective layers, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of reduced light output performance of semiconductor light-emitting devices, lower reflectivity of contact electrodes, etc., to improve light output characteristics and avoid voids Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

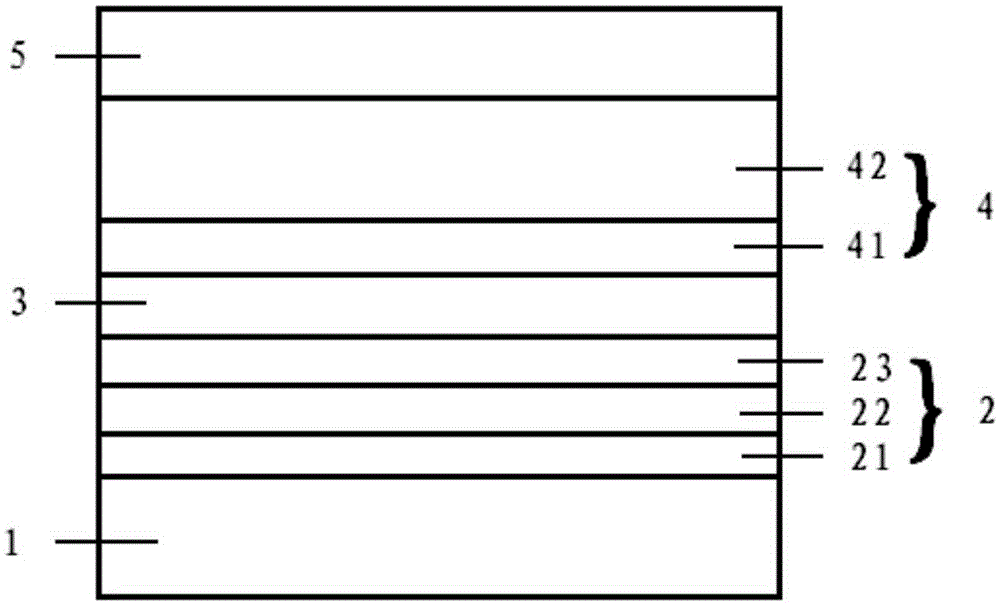

[0018] see figure 1 , the preparation method of the laminated electrode proposed by the present invention comprises the following steps in turn:

[0019] (1) Evaporating the reflective layer 2 on the surface of the semiconductor light emitting unit 1;

[0020] (2) Evaporating the barrier layer 3 on the surface of the reflective layer 2;

[0021] (3) Sputtering on the surface of the barrier layer 3 to form the coalescence inhibiting layer 4;

[0022] (4) Sputtering the oxidation barrier layer 5 on the coalescence inhibiting layer 4 .

[0023] Wherein, in step (1), when the degree of vacuum is less than 1×10 -6 The reflective layer 2 was evaporated under the condition of Torr. First put the semiconductor light-emitting unit into the evaporation chamber, and evacuate until the vacuum degree is less than 1×10 -6 When torr, start the evaporation process, sequentially evaporate TiO 2 Layer 21, Ti 3 o 5 Layer 22 and Ta 2 o 5 Layer 23; after evaporation finishes, obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com