Method for preparing patterned doped crystalline silicon thin film for solar cells

A solar cell and thin film preparation technology, applied in the field of solar cell material preparation, can solve the problems of limiting device structure and adjustable range of process conditions, increasing the complexity of process control, and being unfavorable to solar cell performance, so as to reduce storage time, Wide selection range, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

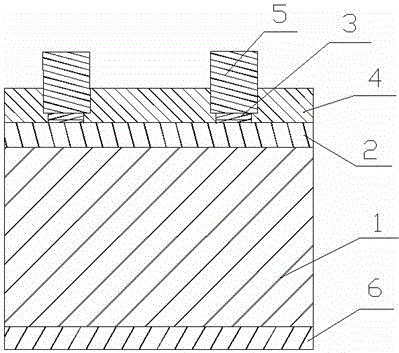

[0019] Such as figure 1 The crystalline silicon solar cell using the patterned doped silicon film as the selective emitter is prepared according to the following steps:

[0020] 1) Phosphorus (or boron) is diffused on the single crystal silicon wafer 1, and then the surface impurity layer is removed to obtain a lightly doped n-type crystalline silicon thin film emitter 2; vapor deposition method can also be used to deposit doped silicon on the single crystal silicon wafer 1. Doped silicon thin film and modified by subsequent treatment process to obtain lightly doped n-type crystalline silicon thin film emitter 2 (deposited by PECVD method, process parameters are: source gas flow rate SiH 4 :PH 3 :H 2 = 1sccm:0.2 sccm:100 sccm, deposition pressure 35 Pa, power density 0.2W / cm 2 , substrate temperature 240 o C, the deposition thickness is 200 nm; after the deposition, use H 2 protection carried out 1050 o C, 20s rapid heat treatment modification);

[0021] 2) Depositing a...

Embodiment 2

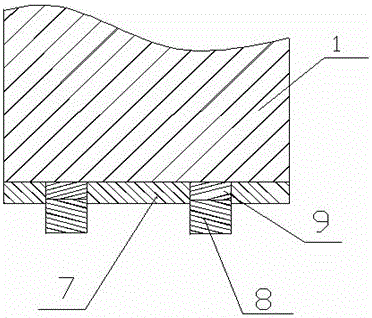

[0026] Such as figure 2 The regionalized back electric field of the crystalline silicon solar cell shown is obtained by the following process:

[0027] 1) A patterned mask plate is used to cover the surface of the single crystal silicon wafer (1), and a PECVD method is used to deposit a heavily doped patterned silicon film 9 on the back surface with a film thickness of 40 nm.

[0028] 2) The prepared heavily doped patterned silicon film 9 is crystallized by a rapid heat treatment process, and the doping elements in it are activated, and the heat treatment temperature is 1300 o C, the time is 5 s.

[0029] 3) Depositing a back surface passivation layer 7 on the exposed silicon wafer surface except the area covered by the heavily doped silicon film;

[0030] 4) Printing and sintering of the back electrode 8: the printing of the electrode should be able to cover the regionalized heavily doped crystalline silicon film, and the two should form a good ohmic contact.

Embodiment 3

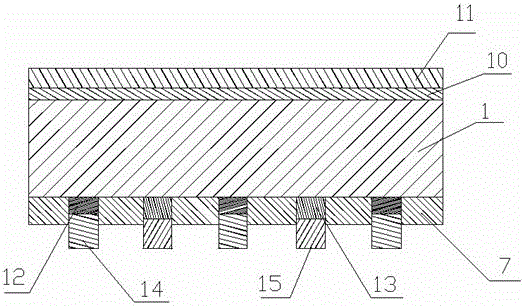

[0032] Such as image 3 The shown back crystalline silicon solar cell is prepared as follows:

[0033] 1) Deposit back electric field silicon film 12 (thickness: 30nm) and emitter silicon film 13 (thickness: 100nm) on single crystal silicon wafer 1 sequentially using different masks; the alignment between the two templates must be accurate to ensure The resulting two types of films cover the entire back surface and do not interfere with each other. The mask plate is processed according to the design requirements, and the material is stainless steel;

[0034] 2) Rapid heat treatment crystallization of the emitter film 13 and the silicon film 12 in the back electric field, using Ar gas protection, for 1050 o C, 20s rapid heat treatment modification;

[0035] 3) The passivation layer 7 on the back surface is deposited by using a mask to cover the area of the emitter and the back electric field, and the deposited passivation layer needs to cover all areas except the emitter a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com