Brightness and Chroma Calibration Method of LED Display

A technology of LED display screen and calibration method, which is applied in the field of display calibration, can solve the problems of high interference efficiency, long time consumption, unfavorable large-scale, large-scale LED display screen calibration, etc., to achieve reduced calibration difficulty, high precision, and save on-site The effect of correcting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

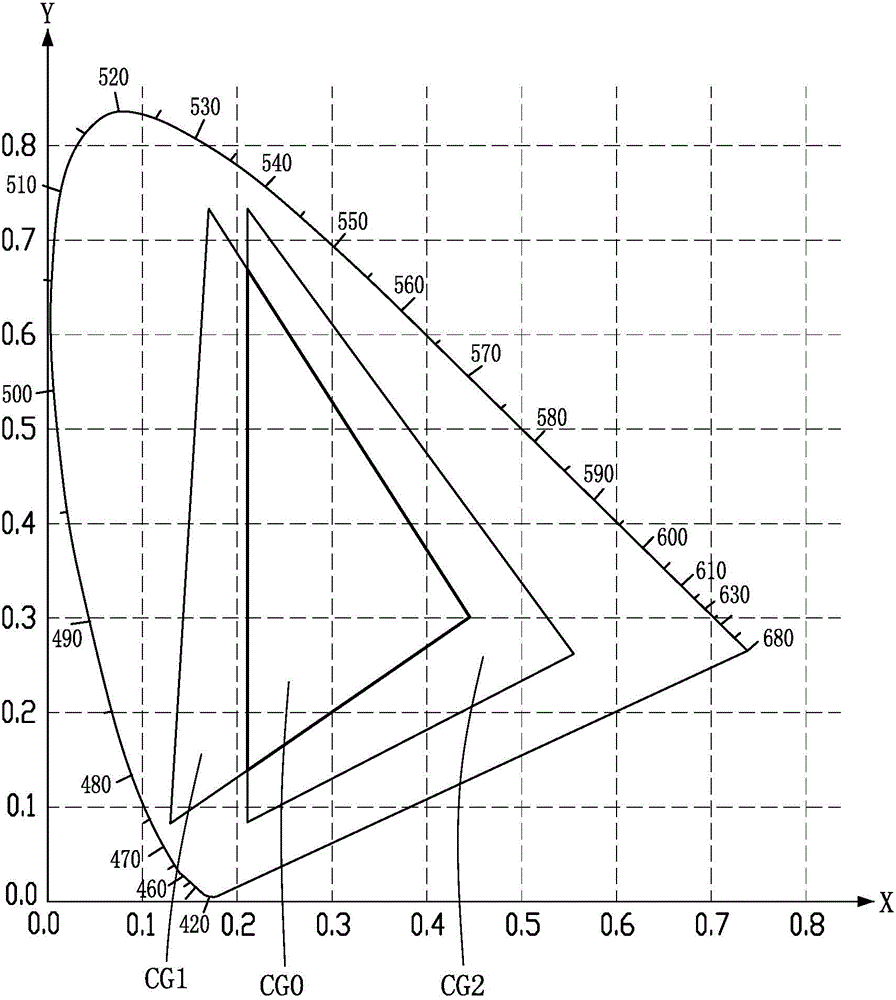

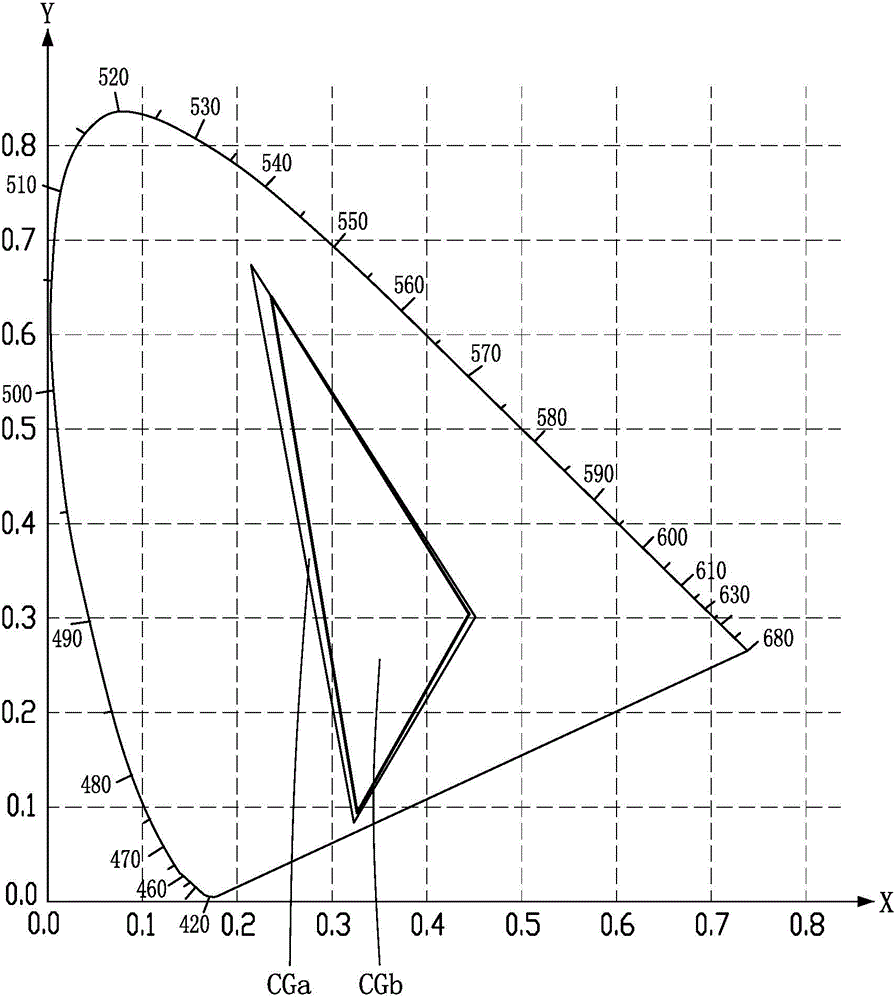

[0018] Specifically, a method for correcting brightness and chromaticity of an LED display screen proposed by an embodiment of the present invention includes, for example, the following steps S1 to S3, and each step will be described in detail later. Wherein, the LED display screen includes a plurality of LED display modules spliced together, and each LED display module includes a plurality of pixels. The plurality of LED display modules can be taken from the same batch, or from different batches; a single pixel includes one or more LEDs, and in the case of multiple LEDs, for example, it includes red ( R), green (G), and blue (B) three-color LEDs, may even include white (W) LEDs or yellow (Y) LEDs, and of course may only include two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com