Self-centering friction drive lime rotary kiln

A lime rotary kiln and friction transmission technology, applied in the direction of rotary drum furnace, furnace, lighting and heating equipment, etc., can solve the problems of reduced service life of supporting wheels and rolling rings, excessive driving power consumption, increased maintenance costs, etc., to achieve The effect of reducing parts, reducing investment costs, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Describe the concrete content of the present invention in detail below in conjunction with accompanying drawing:

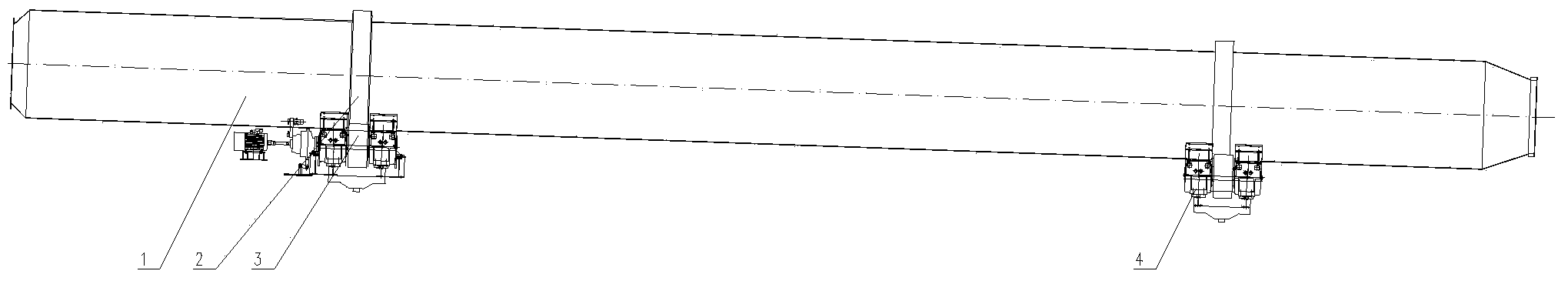

[0020] See figure 1 , is a structural schematic diagram of an embodiment of the self-adjusting friction transmission lime rotary kiln of the present invention, including the active supporting roller group 3, the driven supporting roller group 4, the kiln body 1 and the rolling ring 2, and the kiln body 1 is respectively equipped with active supporting rollers Group 3 and driven supporting wheel group 4, wherein the driving supporting wheel group 3 is matched with the rolling ring 4 on the feed side of the kiln body 1, and the driven supporting wheel group 4 is matched with the rolling ring 4 on the discharging side of the kiln body 1 Cooperate, the driving supporting wheel group 3 has a driving device, and the driven supporting wheel group 4 does not.

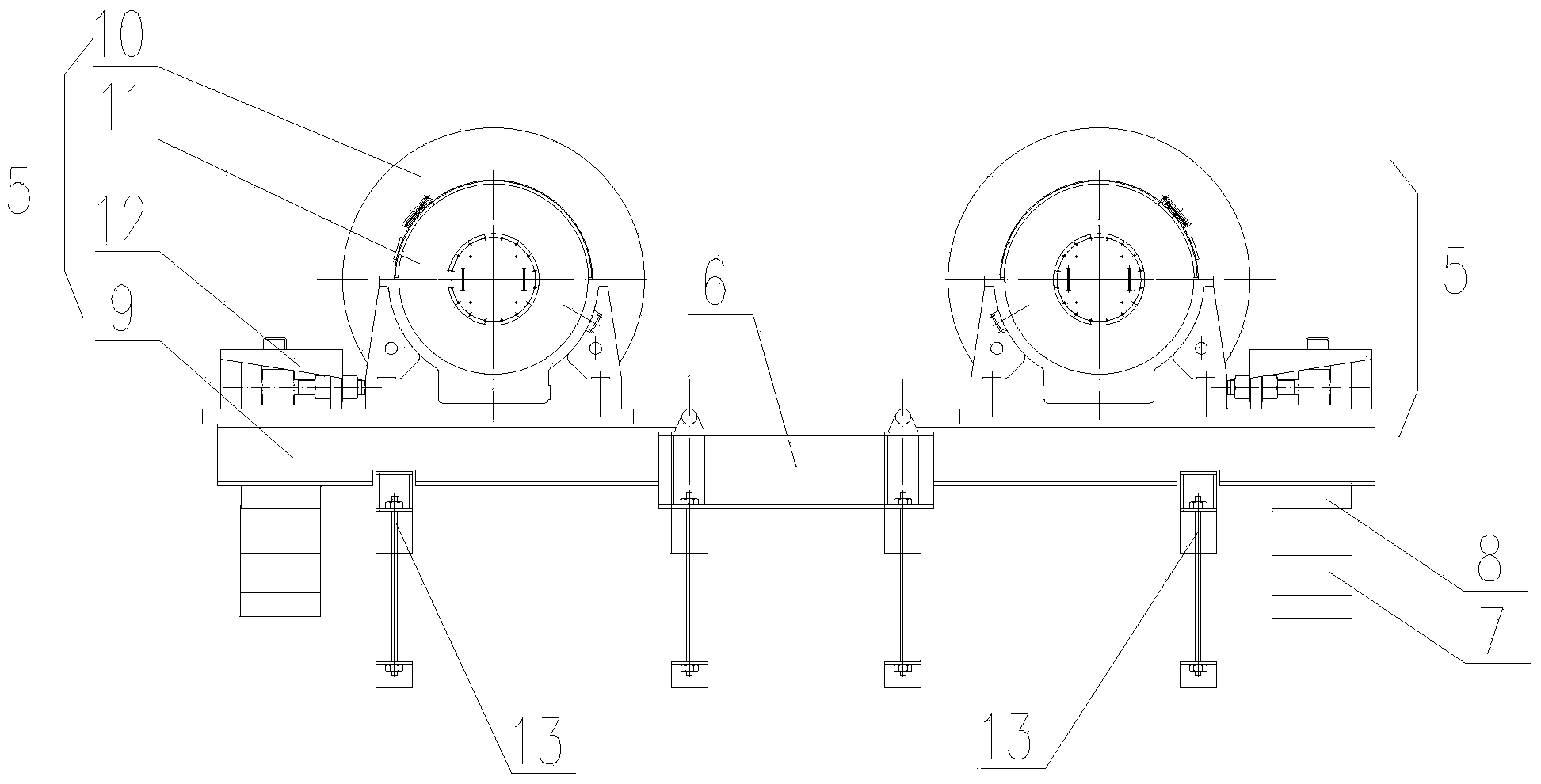

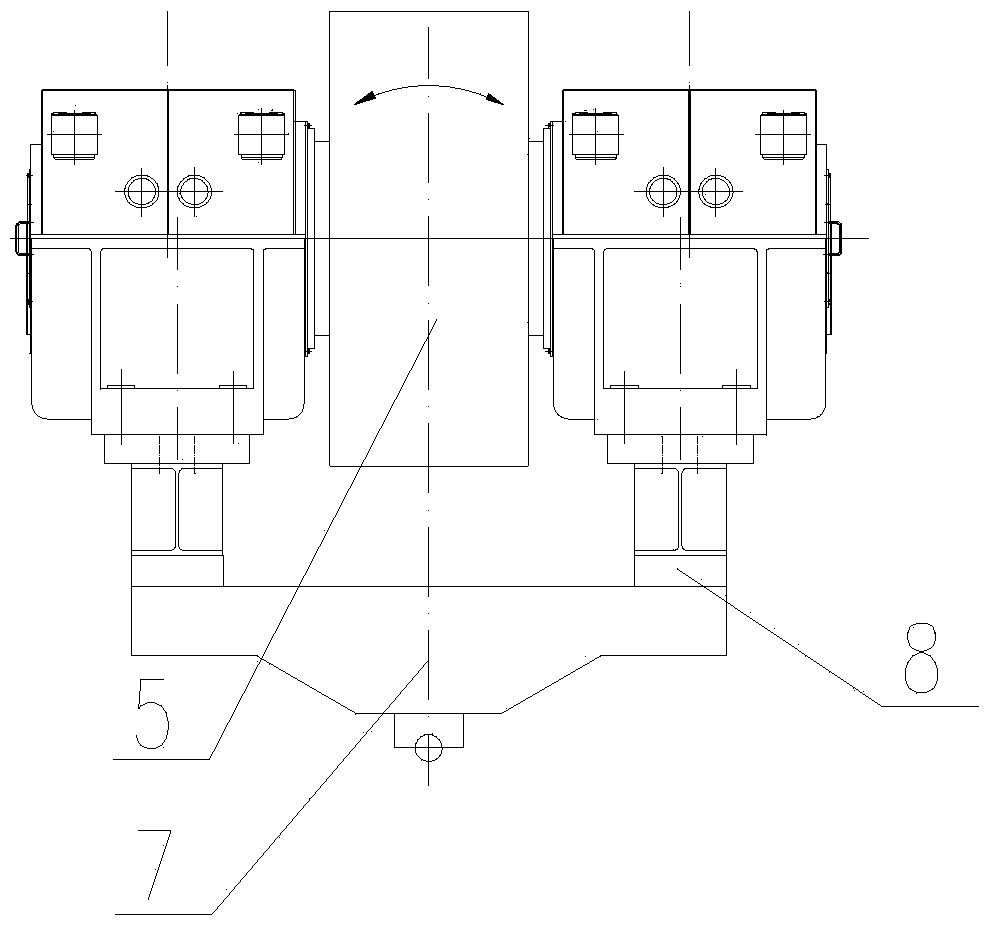

[0021] See figure 2 , image 3 , the driven roller group 4 includes two supporting roller devices 5 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com