Liquid crystal backlight module

A backlight module and liquid crystal technology, applied in optics, light source, shading, etc., can solve problems such as small attachment area of black and white double-sided tape and plastic frame, influence of display panel display effect, light leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

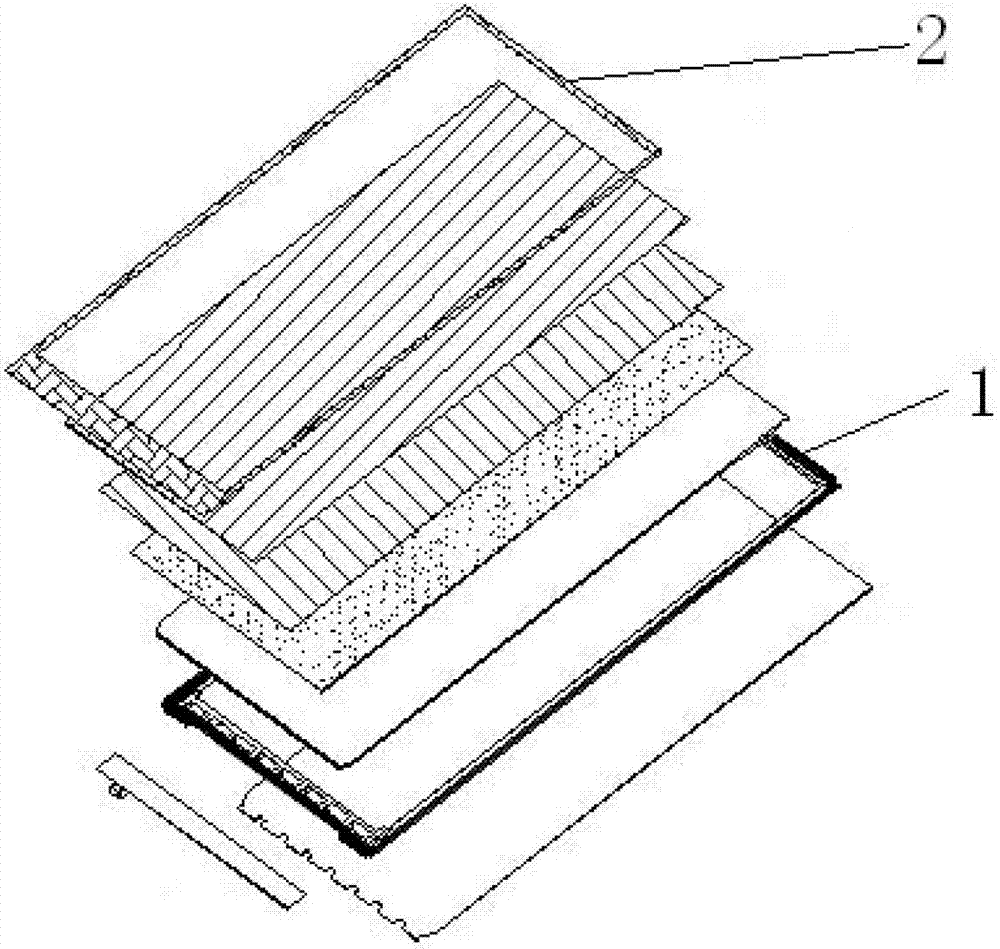

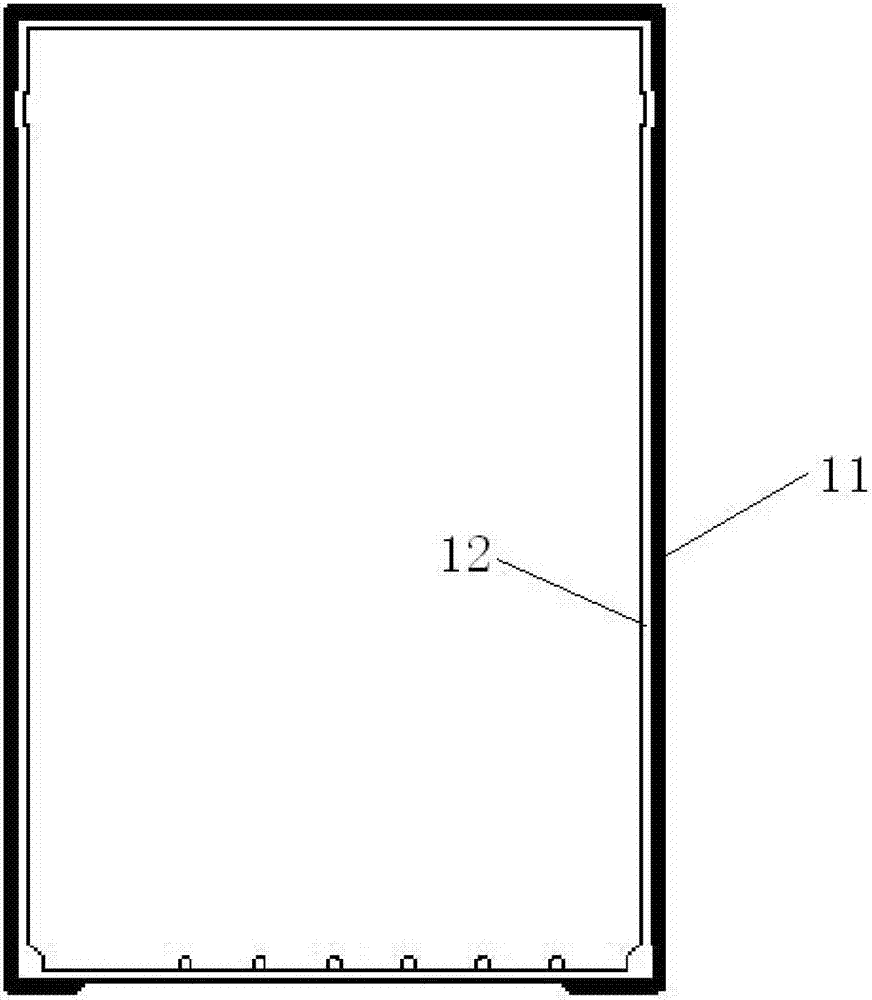

[0018] refer to figure 2 and image 3 The liquid crystal backlight module of the present invention includes a plastic frame 1 and a black and white double-sided adhesive tape 2, the plastic frame 1 is a hollow frame structure, the plastic frame 1 includes a first frame 11 on the outside and a second frame 12 on the inside, the first frame 11 It is closely connected with the second frame 12 , the surface of the first frame 11 is black, and the surface of the second frame 12 is white. The first frame 1 is thicker than the second frame.

[0019] When manufacturing the plastic frame 1, a double-shot molding process can be used. The first shot molds the first frame 11, and the second shot molds the second frame. The material injected into the first shot is black PC plastic, and the material injected into the second shot is white. PC plastic, here the two-color molding of the plastic frame 1 does not limit the molding sequence of the first frame 11 and the second frame 12, for ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com