A flexible rubber sealing ring used between an automobile engine and a radiator

A technology for automotive engines and radiators, applied in the field of auto parts, can solve problems such as difficult operation, low assembly efficiency, and product tearing and damage, and achieve the effects of simple vulcanization process, improved heat dissipation efficiency, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

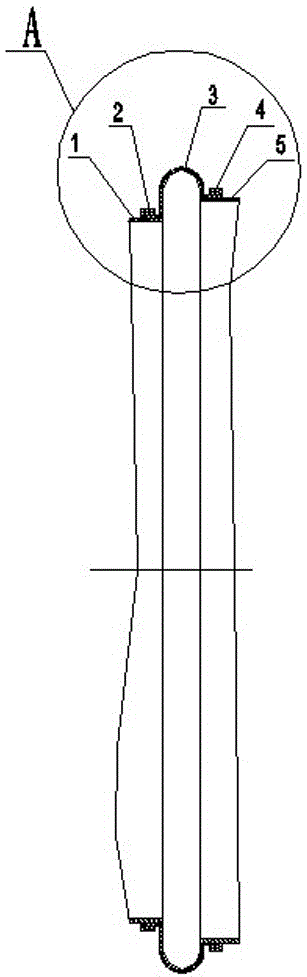

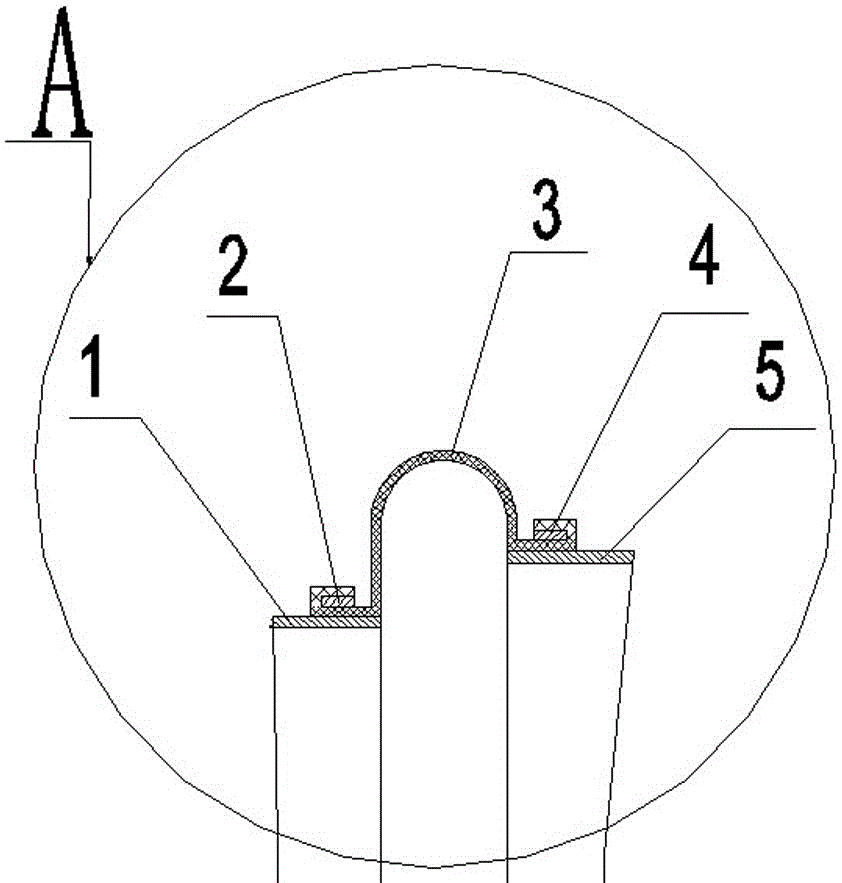

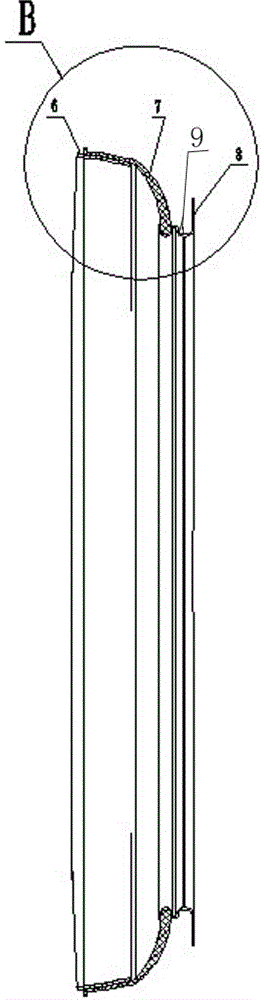

[0025] The present invention as image 3 , 4 shown.

[0026] A flexible rubber sealing ring used between an automobile engine and a radiator, comprising a flexible rubber sealing ring 7, one end of the flexible rubber sealing ring 7 is connected to the wind deflector 8, and the other end is connected to the engine sealing cover 6 Connection, the shroud 8, the protective cover 6 and the flexible rubber sealing ring 7 are split structures, wherein the flexible rubber sealing ring 7 is in the shape of a "bell mouth", and the cross-sectional shape of its small end is designed in the shape of an "O-ring" , corresponding to the shroud 8 is provided with an assembly groove 9; the "horn mouth" at the big end is provided with a shield cover 6 that matches its inner wall, so that it can be closely attached to the shield cover 6 in a natural state and can be relatively displacement.

[0027] The wall thickness of the flexible rubber sealing ring 7 is gradually deformed from thin to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com