Fluid engine and manufacturing method and application device thereof

An engine and fluid technology, applied in the direction of machines/engines, mechanical power generating mechanisms, mechanical equipment, etc., can solve the problems of incomplete energy conversion, utilization, energy incomplete conversion, utilization, and low energy utilization rate, and achieve a solution The effect of fuel shortage, easy overload protection, and elimination of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

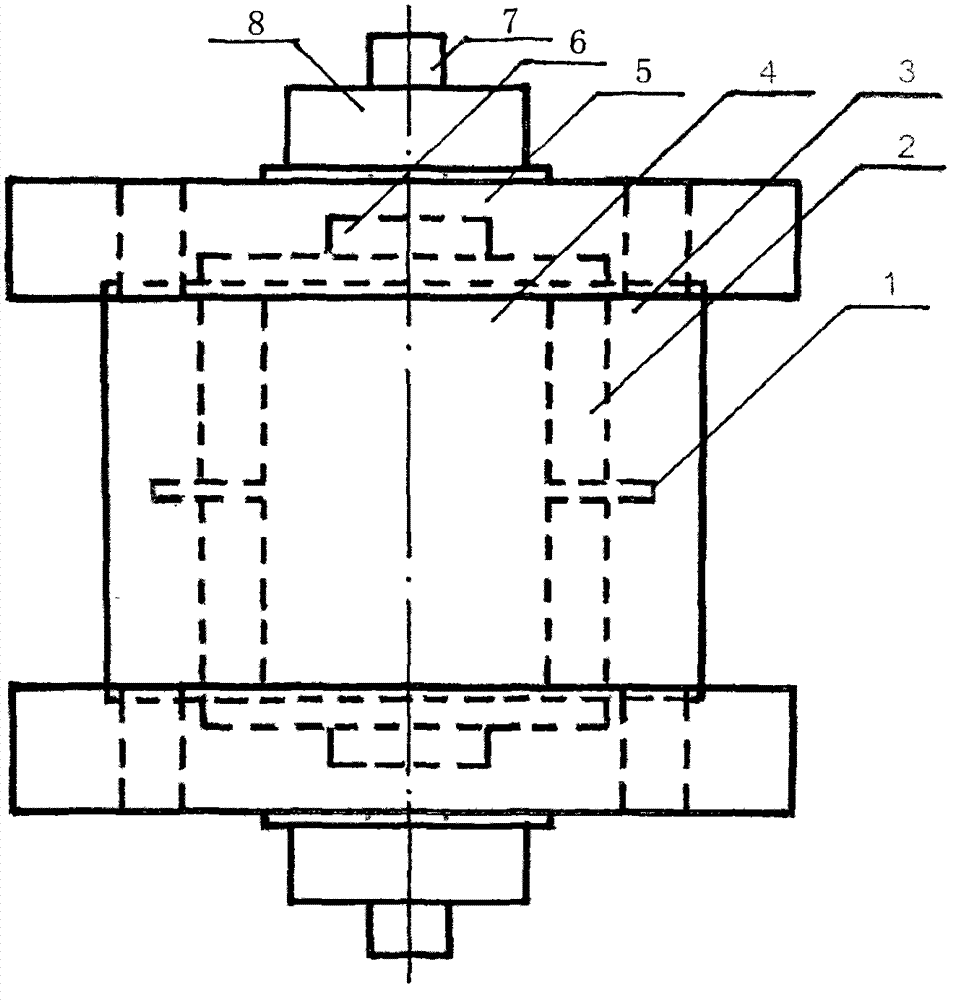

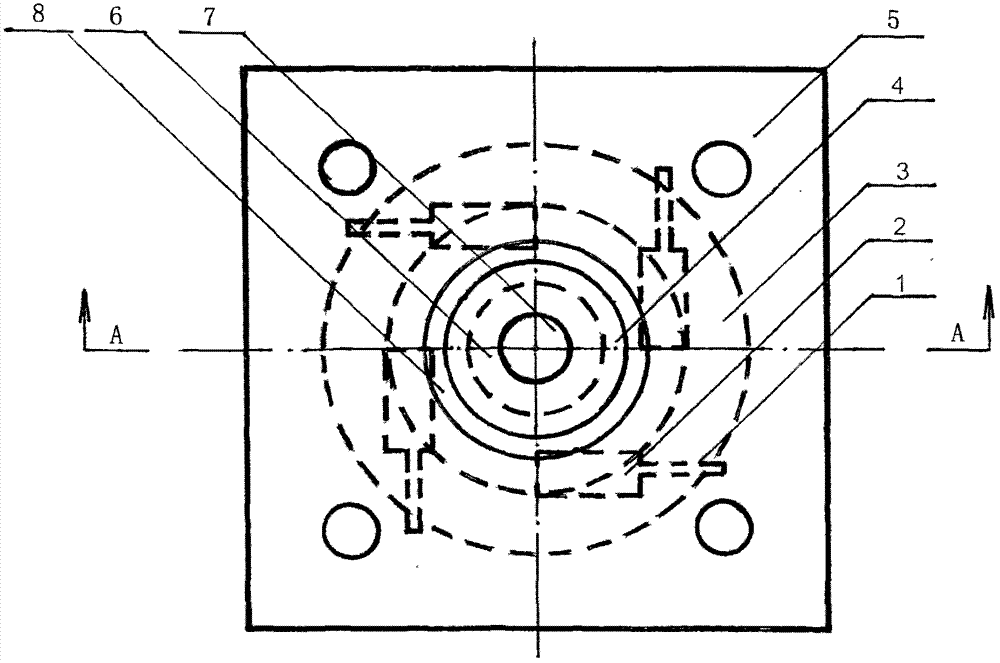

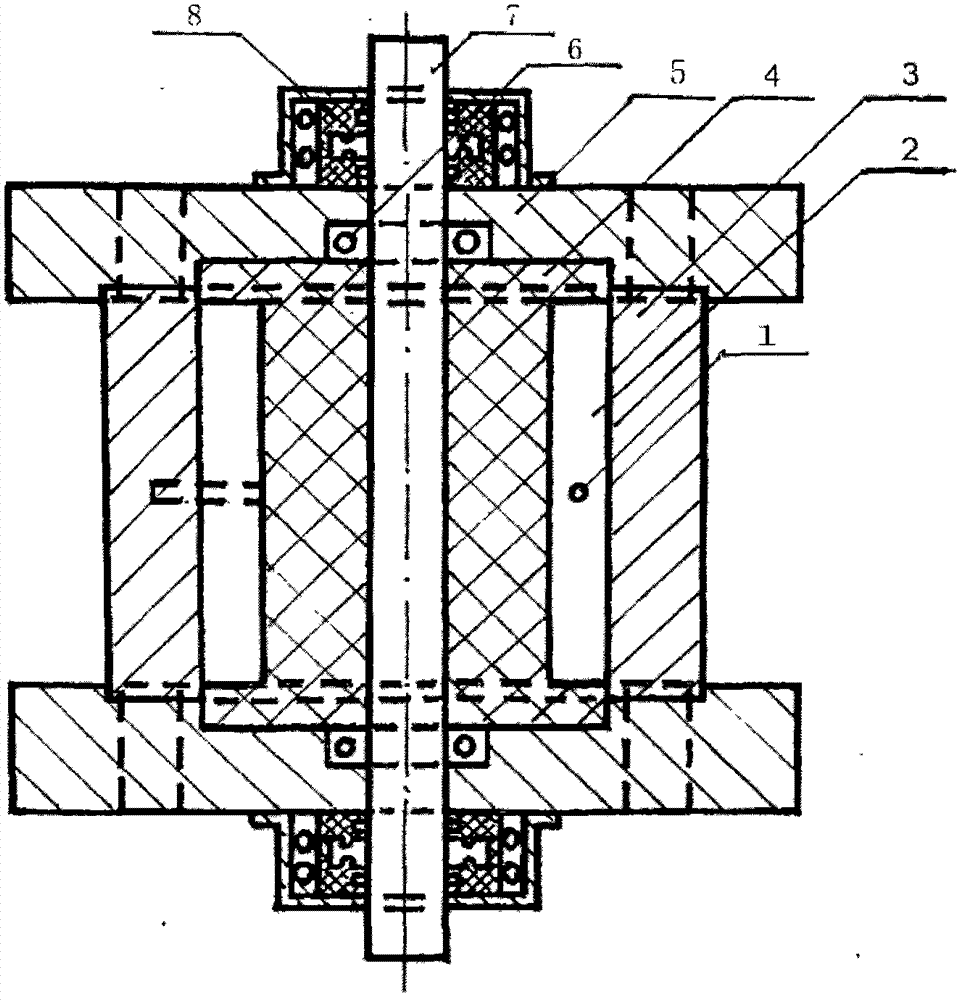

[0043] A volume cavity (2) capable of generating interaction force is formed between the stator (3) and the rotor (4), and the volume cavity (2) is distributed between the stator (3) and the rotor (4) to form a circle. When the working fluid of a certain pressure output by the working fluid adjuster fills the volume chamber (2) through the inlet (1), the stator (3) and the rotor (4) will be staggered, and the first one of the rotor (4) The volume cavity part will form a new volume cavity with the second volume cavity part of the stator (3), and the same misalignment will occur, and so on, and a round of misalignment will result in a circular rotation. Keeping the pressure of the working fluid will make the The engine runs continuously.

[0044] Both ends of the rotor (4) and the stator (3) are respectively provided with end covers (5), and the center of the end cover (5) is equipped with a bearing (6), and the central axis (7) of the rotor (4) is limited by the bearing (6), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com