Underwater wellhead assembly for shallow water

An underwater wellhead and assembly technology, applied in wellbore/well components, sealing/packaging, earth-moving drilling, etc., can solve the problems of time-consuming, low efficiency, and complicated tie-back process of mudline hanger devices, etc. Achieve the effect of reducing the difficulty and uncertainty of installation, good sealing performance and locking effect, and reducing the risk of wellhead uplift and annular pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

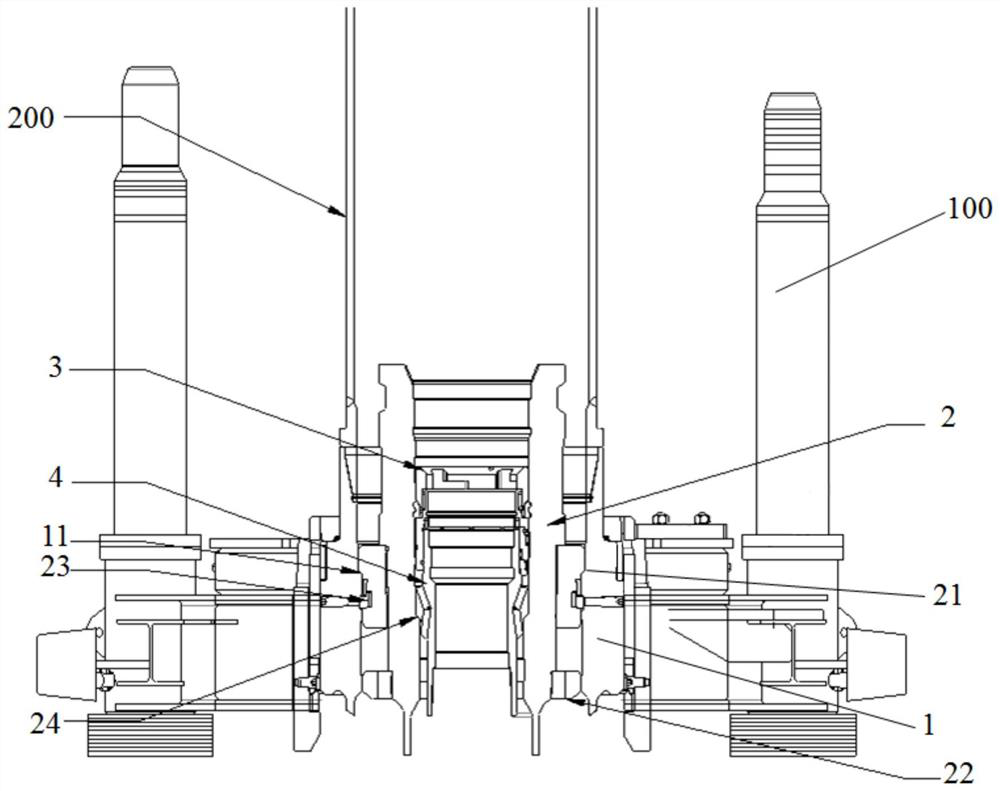

[0030] Example 1: A subsea wellhead assembly for shallow water

[0031] Embodiment 1 provides an underwater wellhead assembly for shallow water, the structure of which will be described in detail below with reference to the accompanying drawings.

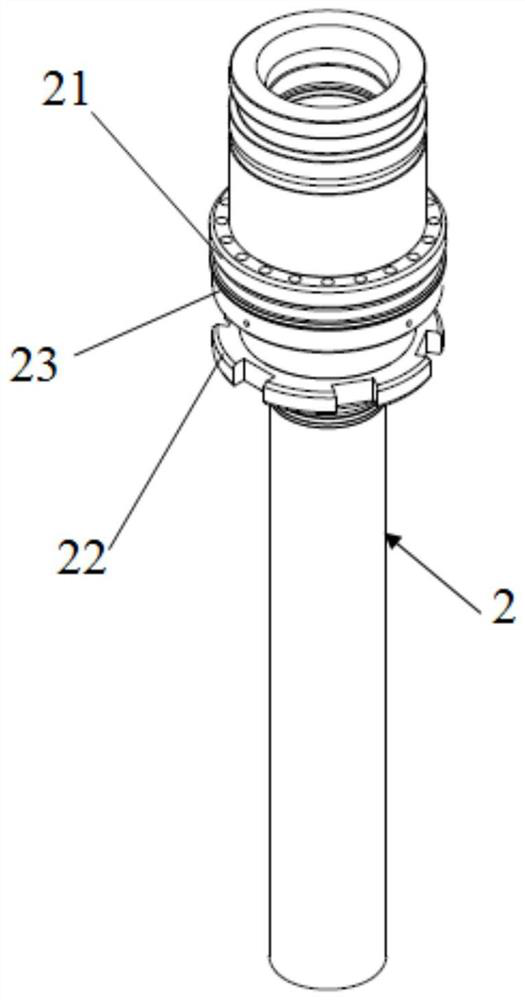

[0032] refer to figure 1 , the subsea wellhead assembly for shallow water includes a low pressure wellhead 1 , a high pressure wellhead 2 , an annular seal assembly 3 and a casing hanger 4 .

[0033] The low pressure wellhead 1 is located in the outermost layer, the high pressure wellhead 2 is set in the low pressure wellhead 1, the casing hanger 4 is seated in the high pressure wellhead 2; the annular seal assembly 3 is sealed between the casing hanger 4 and the high pressure wellhead 2. At the same time, the locking of the annular seal assembly 3 between the casing hanger 4 and the high pressure wellhead 2 is realized.

[0034] Preferably, the longitudinal centerlines of the low-pressure wellhead 1, the high-pressure wellhead 2,...

Embodiment 2

[0058] Embodiment 2: A kind of installation method of underwater wellhead assembly in shallow water sea area

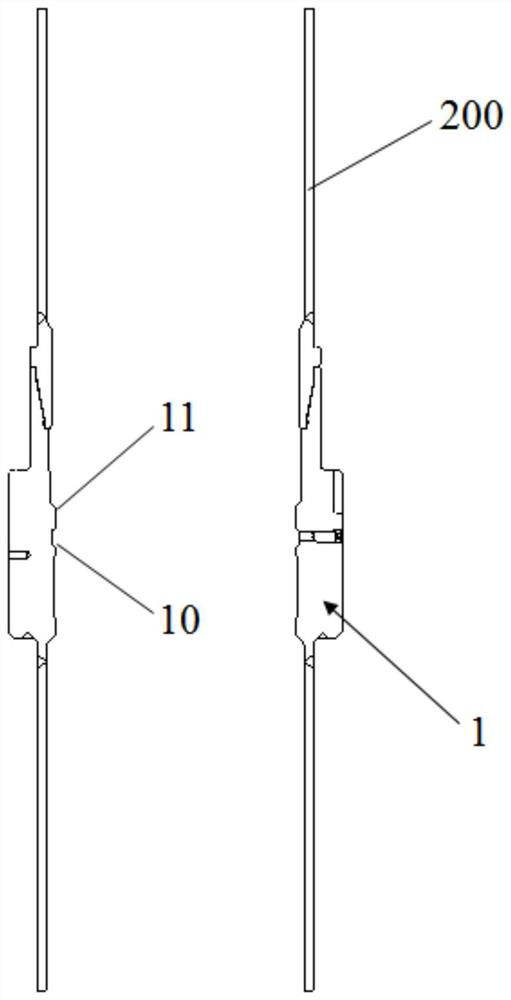

[0059] Embodiment 2 provides an installation method of an underwater wellhead assembly in a shallow sea area, using the underwater wellhead assembly provided in Embodiment 1, and the method includes the following steps:

[0060] Step S1: the lower part of the low pressure wellhead 1 is connected with a plurality of surface conduits; the top of the low pressure wellhead 1 is butted with a plurality of tieback joints 200, wherein the top of the low pressure wellhead 1 and the lowest tieback joint 200 pass through the reverse connection. Tighten the butt clockwise, and connect the multiple tie-back joints 200 above the lowest tie-back joint 200 by clockwise tightening and butt joint; control the low-pressure wellhead 1 and the surface conduit to go down into the wellhead together through the tie-back nipple 200 until the installed in the intended location.

[0061] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com