Node structural component for disassembling and assembling of corner plug matched with profiled bar

A technology for profiled materials and structural parts, applied in the direction of connecting components, rods, slender elements, etc., can solve the problems of easy loosening and deformation, time-consuming and labor-intensive, high cost, etc., and achieve the effect of convenient disassembly and assembly, and convenient and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

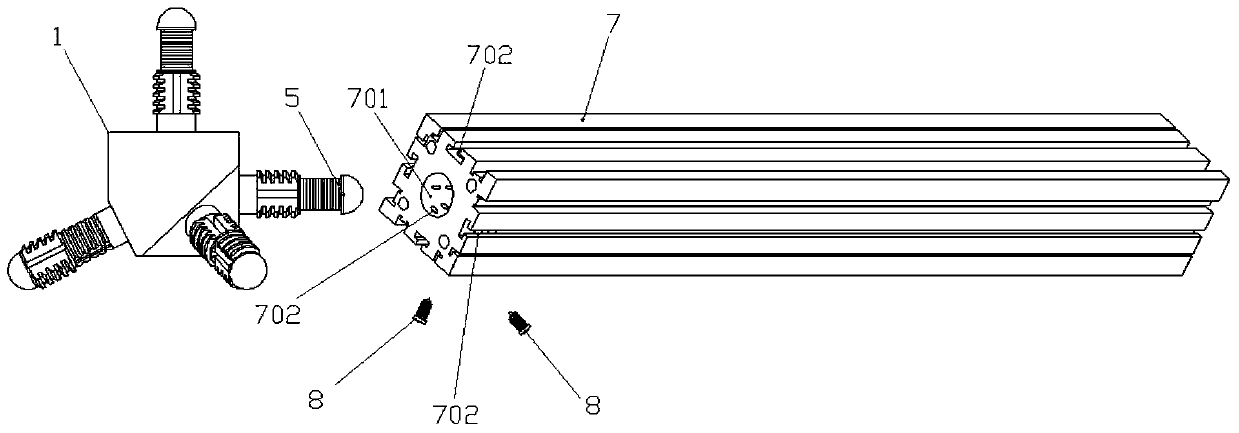

[0026] refer to Figure 1 to Figure 9 As shown, the corner plug matched with the profiled bar disassembles and assembles the node structure,

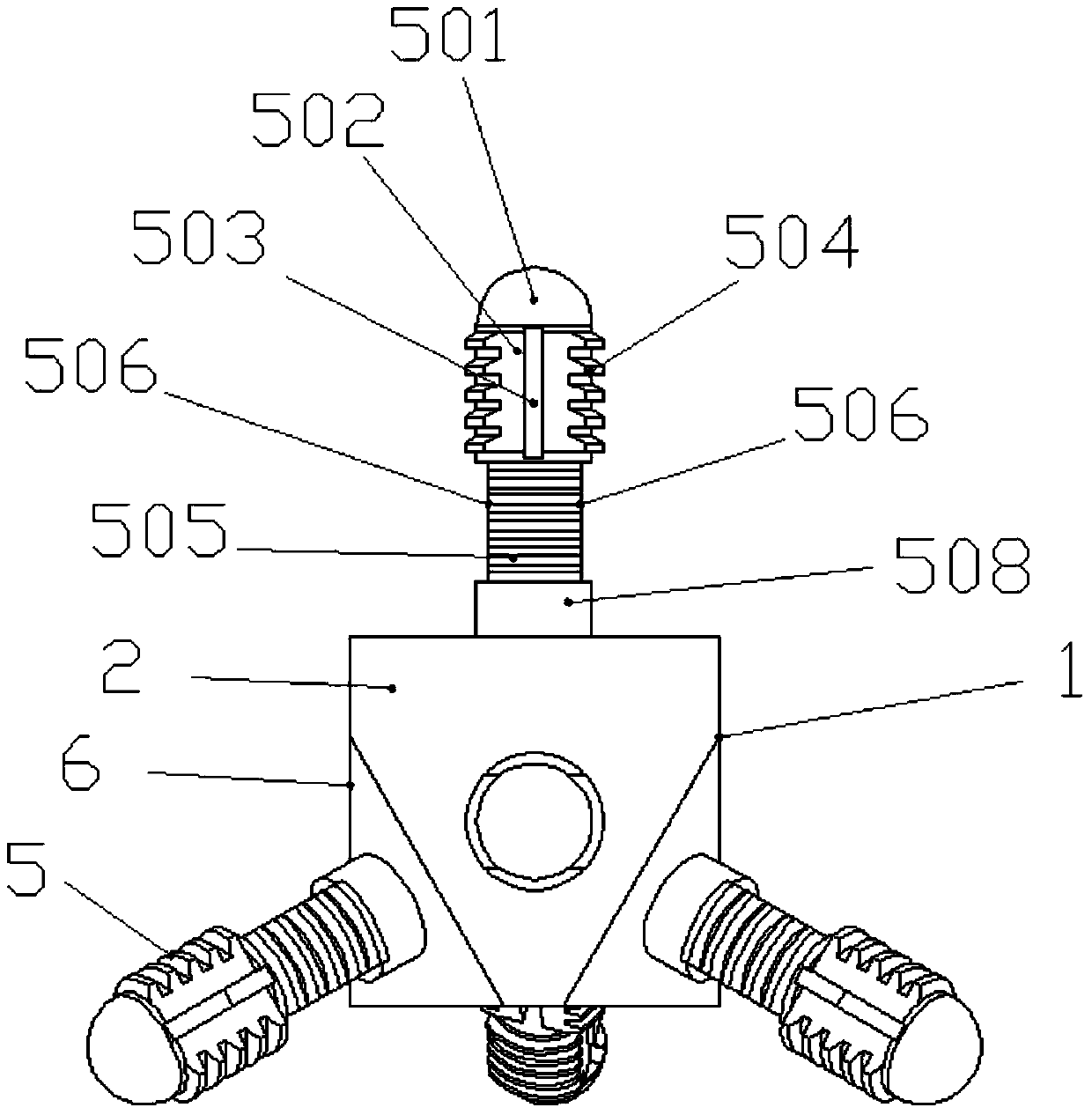

[0027] Including a node structure 1, the node structure 1 is surrounded by an exposed decorative surface 6 and a profiled material assembly shielding surface 2, and the profiled material assembly shielding surface 2 is provided with a multi-directional angle connection plug 5, wire and cable The via hole 4 and the wire and cable groove 3, the multi-directional angle connection plug 5 is provided with a quick introduction head 501, which can be inserted into the hole structure 701 of the profiled material or the pipe material 7 conveniently and quickly, and it is connected into a complex joint with nodes. Modeling skeleton9.

[0028] Further, the multi-directional angle connection plug 5 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com