Prestressed reinforced concrete H-shaped support pile based on pre-tensioning method

A technology of prestressed steel bars and pretensioning, applied in the field of pile foundations, can solve problems such as low construction efficiency, low soil compaction, and poor mechanical properties, and achieve the effects of increasing the probability of anti-leakage and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

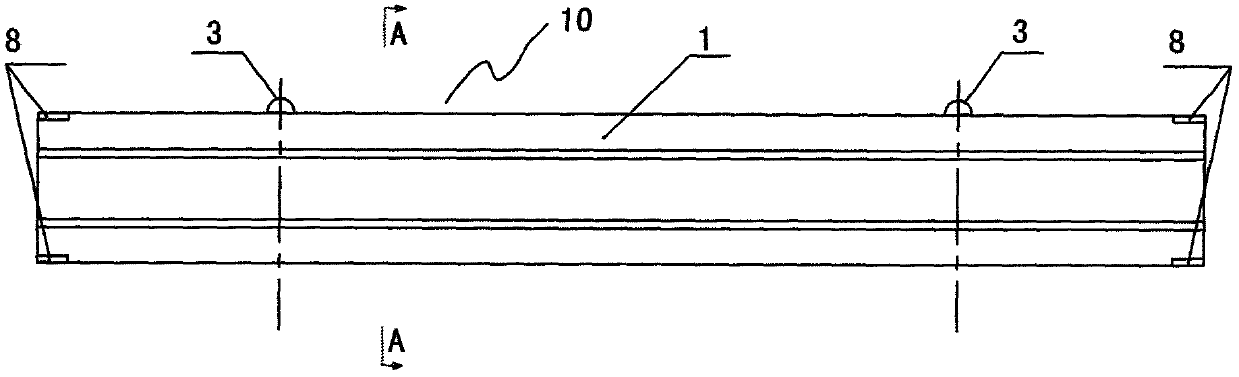

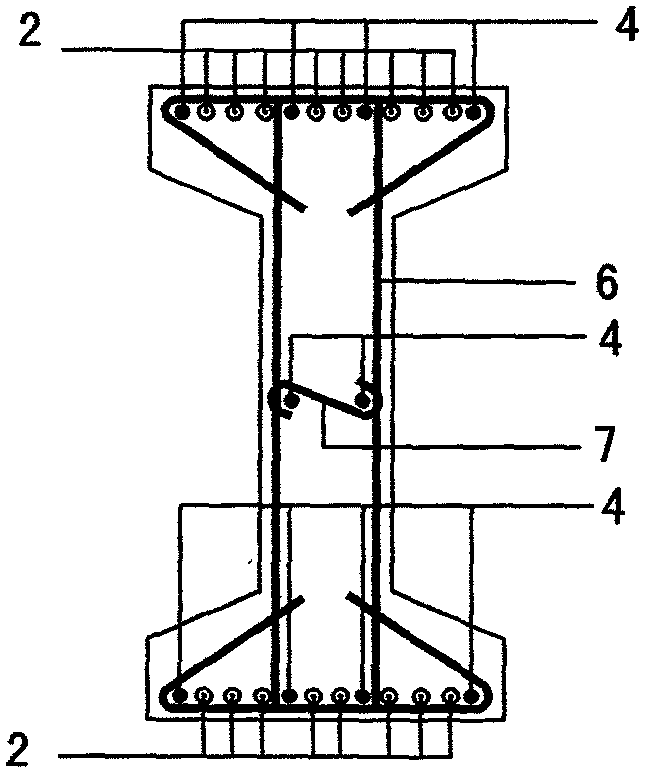

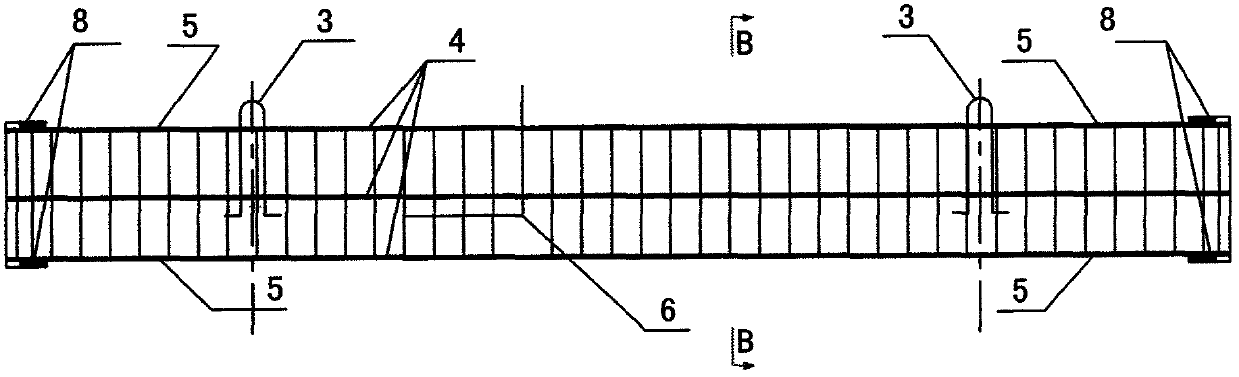

[0031] Figure 1 to Figure 9 Shown an embodiment of the present invention, it comprises a standard pile section 10 with I-shaped section, and this standard pile section comprises a steel bar framework, and the upper and lower planes of the section of this steel bar framework are provided with a plurality of horizontally arranged diameters of 9mm along the The high-strength steel strands arranged symmetrically on the vertical center line are used as the prestressed reinforcement 2. The quantity of the prestressed reinforcement is determined according to the size of the internal force, usually 5, 7 or 9, and the prestressed reinforcement in this embodiment is 9;

[0032] The standard pile segment 10 is 0.207L away from the two ends (L is the length of the standard pile segment 10). There are suspension rings 3 everywhere, and the position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com