I-section prestressed reinforced concrete support pile by centrifugal pouring

A prestressed steel bar, centrifugal pouring technology, applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of poor horizontal and lateral earth pressure mechanical properties, unfavorable saving of building materials resources, surrounding environmental pollution, etc., and achieve construction time. Shorten, improve pile driving efficiency, improve quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

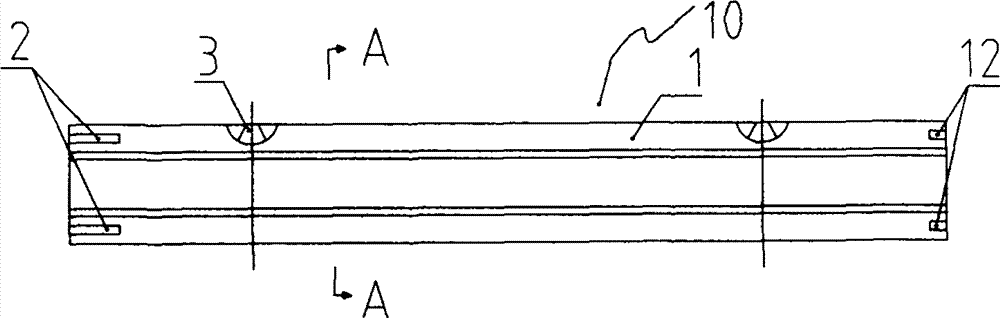

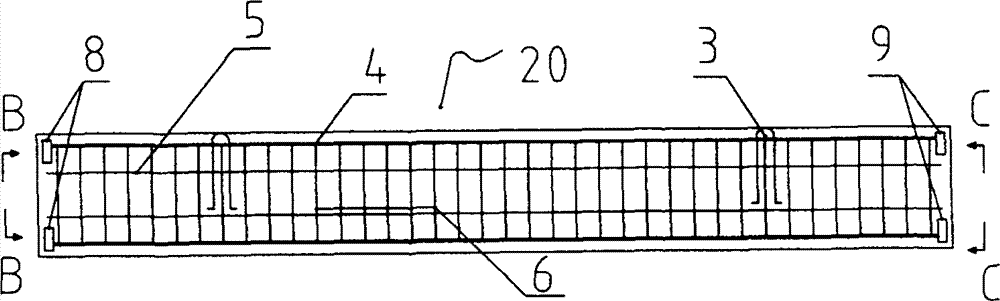

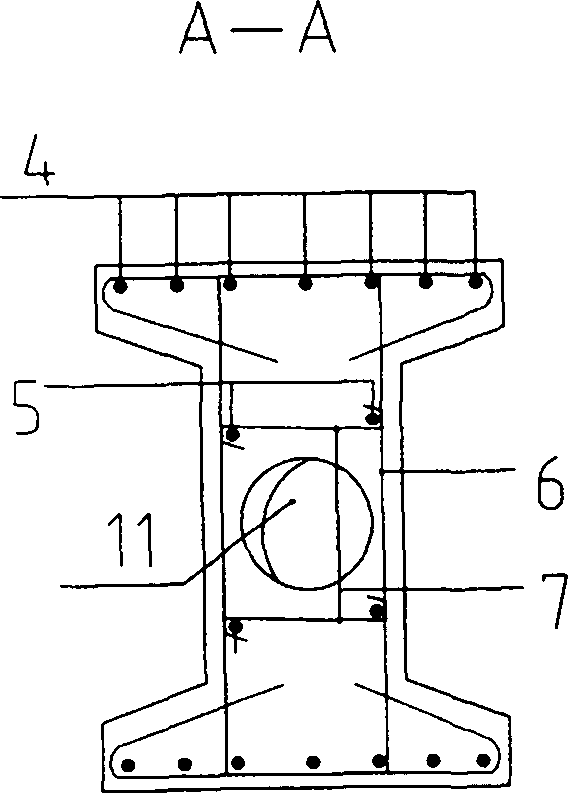

[0028] Figure 1 to Figure 13 An embodiment of the present invention is shown, which includes a standard pile segment 10 with an I-shaped section, and the left and right sides of the I-shaped section are trapezoidal, such as figure 2 Shown; Its trapezoidal slope is 1: 3; This trapezoidal slope is to facilitate demoulding from its two sides after the concrete pouring of said I-shape support pile;

[0029] The circular hole 11 in the center of the I-shaped section is because Figure 13 After the steel form is filled with concrete, the space left by the concrete is completely compacted by high-pressure centrifugal action. The round hole formed by the centrifugal force is the hole left by the centrifugal pouring process, such as figure 2 As shown; the centrifugal force of pouring concrete is zero at the center of the round hole, and gradually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com