Epoxy plaster repaired bridge crane constructing structure and constructing method

A technology of epoxy mastic and track, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of low investment cost, construction period, unreasonable design of pressure plate and expansion joint, track bending, etc., and achieves convenient processing, production, installation and layout , Solve the effect of rail expansion joint top dead, reduce noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

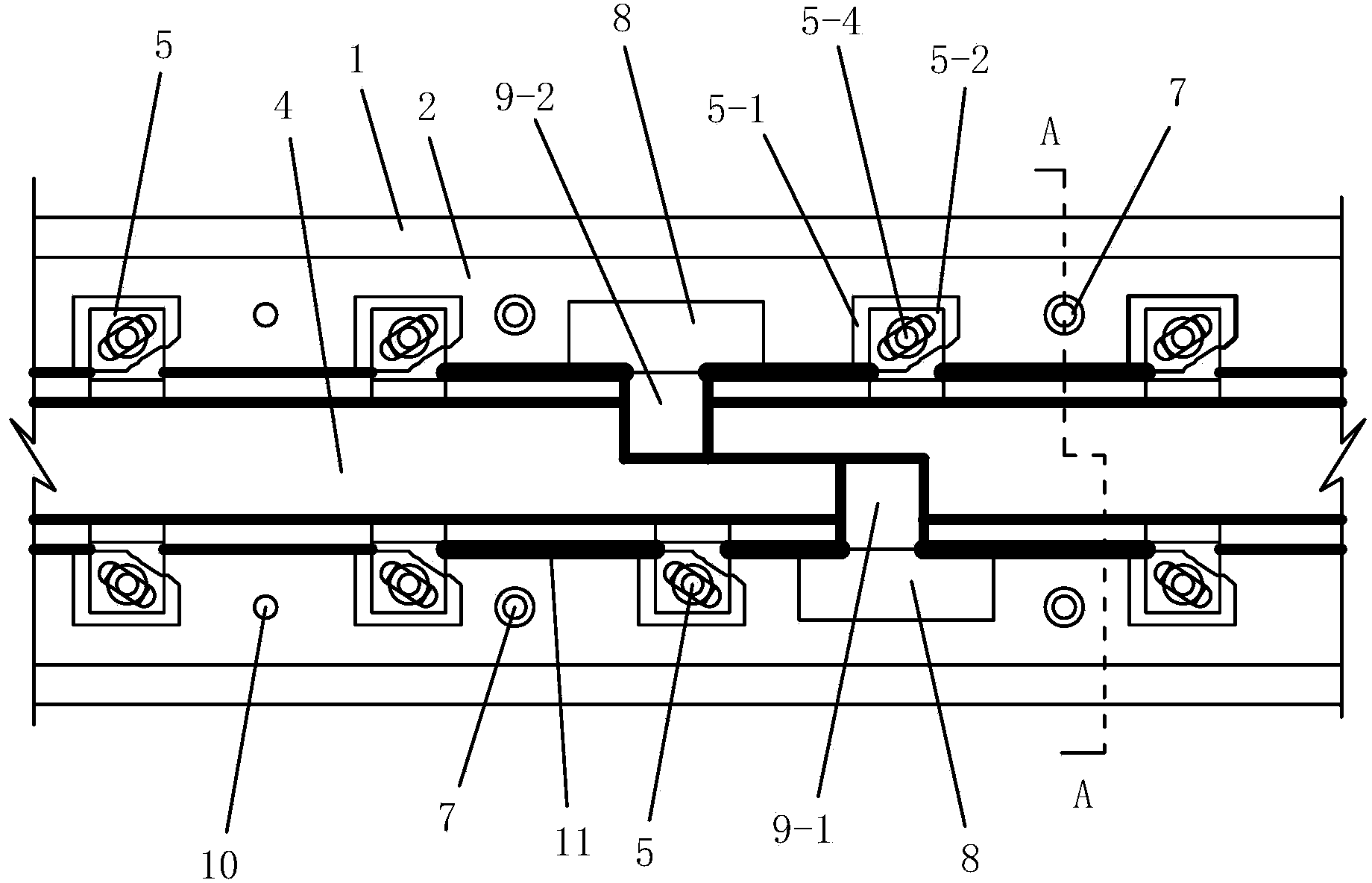

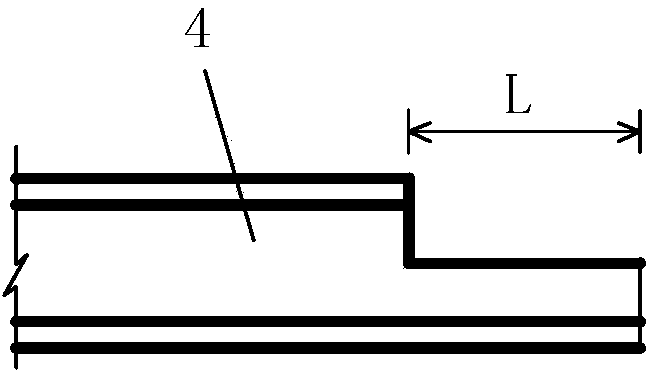

[0045] Such as figure 1 , figure 2 The construction structure of bridge crane track repaired by epoxy glue comprises a leveling steel backing plate 2 tiled on the crane beam 1 along the longitudinal extension direction of the repaired bridge crane rail, and a leveling steel backing plate tiled on the leveling steel backing plate 2 The rail 4 and a plurality of pressing devices arranged from front to back along the length direction of the rail 4 and fixing the rail 4 , an elastic backing plate 6 is placed between the rail 4 and the leveling steel backing plate 2 . The leveling steel backing plate 2 and the crane beam 1 are fastened and connected by a plurality of fasteners. The distance between the bottom surface of the leveling steel backing plate 2 and the upper surface of the crane beam 1 is not less than 5mm, and the cavity between the leveling steel backing plate 2 and the crane beam 1 is filled with epoxy cement and leveled accordingly. An epoxy cement cushion layer 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com