Gas purification treatment device and process with phenolic water treatment for two-sectional type gas producer

A gas generator and purification technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, petroleum industry, etc., can solve the problems of waste of thermal energy resources, living environment pollution, harm, etc., to reduce heat The effect of reducing the loss of high temperature environment and preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

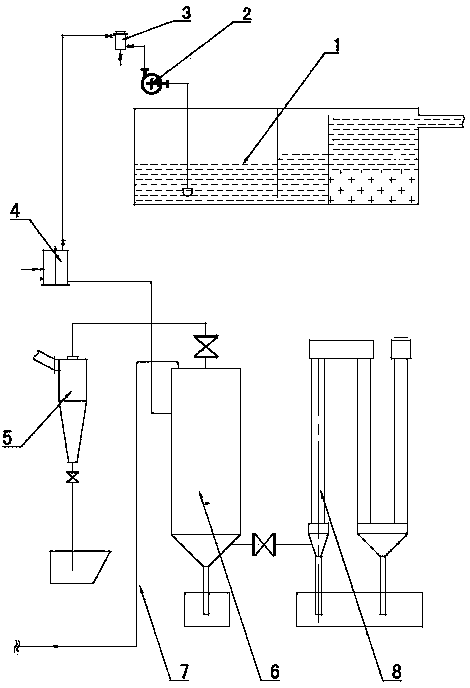

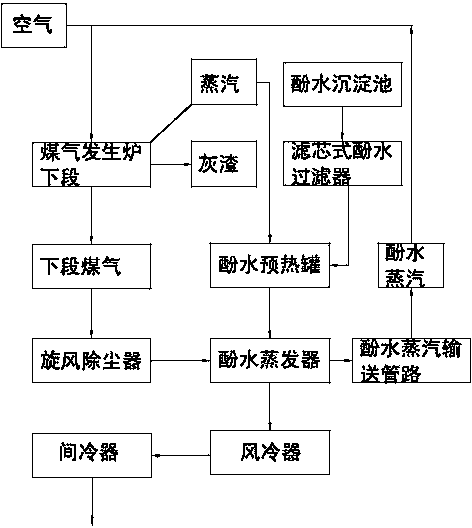

[0022] Figure 1-2 is the best embodiment of the present invention, the following is combined with the appendix Figure 1-2 The present invention will be further described.

[0023] Refer to the attached figure 1 : Two-stage gas generator gas purification treatment device with phenol water treatment, including phenol water sedimentation tank 1, phenol water pump 2, filter element type phenol water filter 3, phenol water preheating tank 4, cyclone dust collector 5 and phenol water The evaporator 6, wherein, the cyclone dust collector 5 is provided with an inner insulation layer cast with refractory materials, and the phenol water evaporator 6 adopts a single-pass tubular heat exchanger.

[0024] The purpose of setting up the phenol water sedimentation tank 1 is to store and precipitate the phenol water discharged from the gas station, to carry out centralized storage management and physical purification of the phenol water, and to avoid the environmental pollution caused by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com