Flat shovel height adjusting mechanism of paddy field laser land leveler

A laser leveling and adjusting mechanism technology, applied in agricultural machinery and tools, agricultural machinery, applications, etc., can solve the problem that the laser controller is difficult to exert control performance, the self-weight leveling shovel rises and falls asymmetrically, and the distance between the leveling shovel and the traction tractor is lengthened and other problems, to achieve the effect of less parts, simple structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

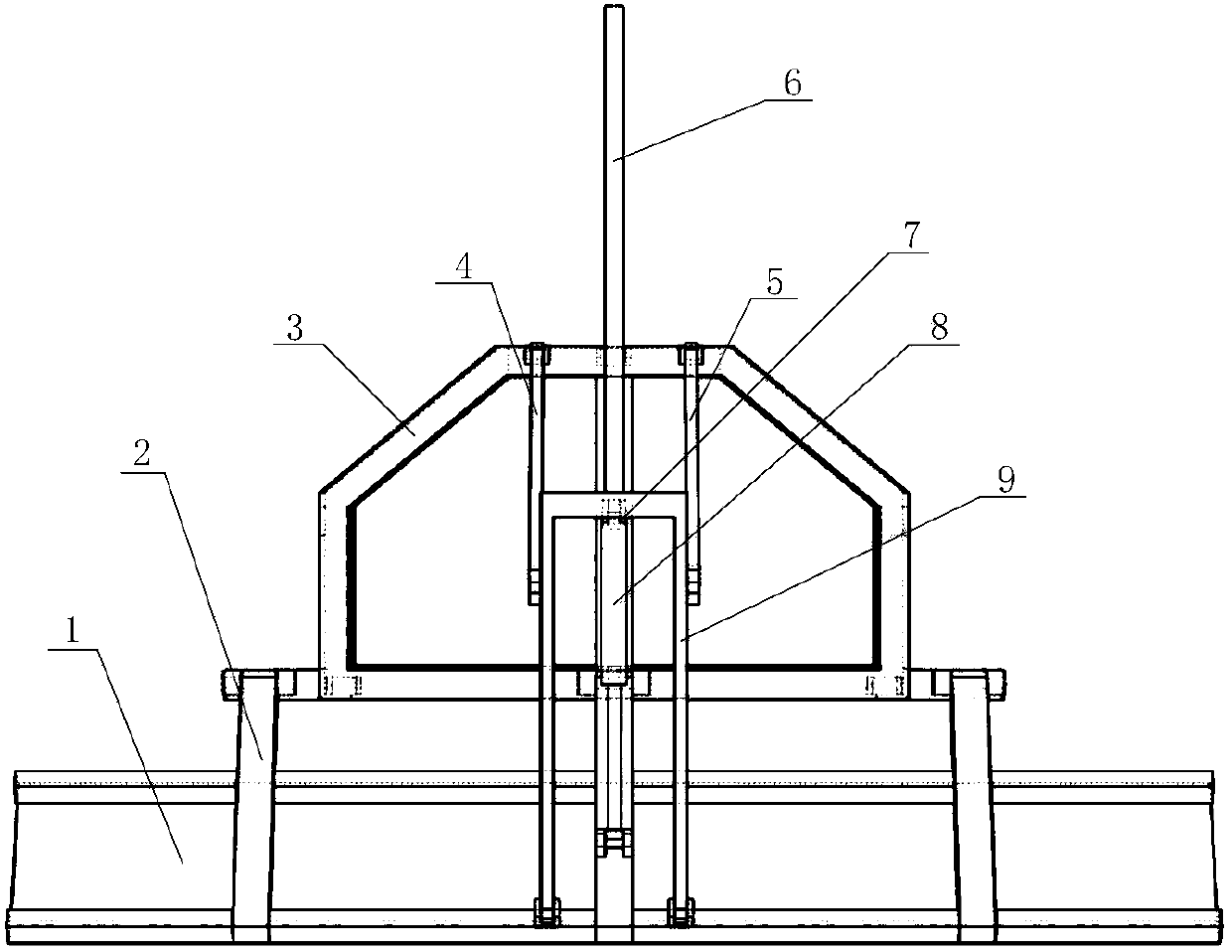

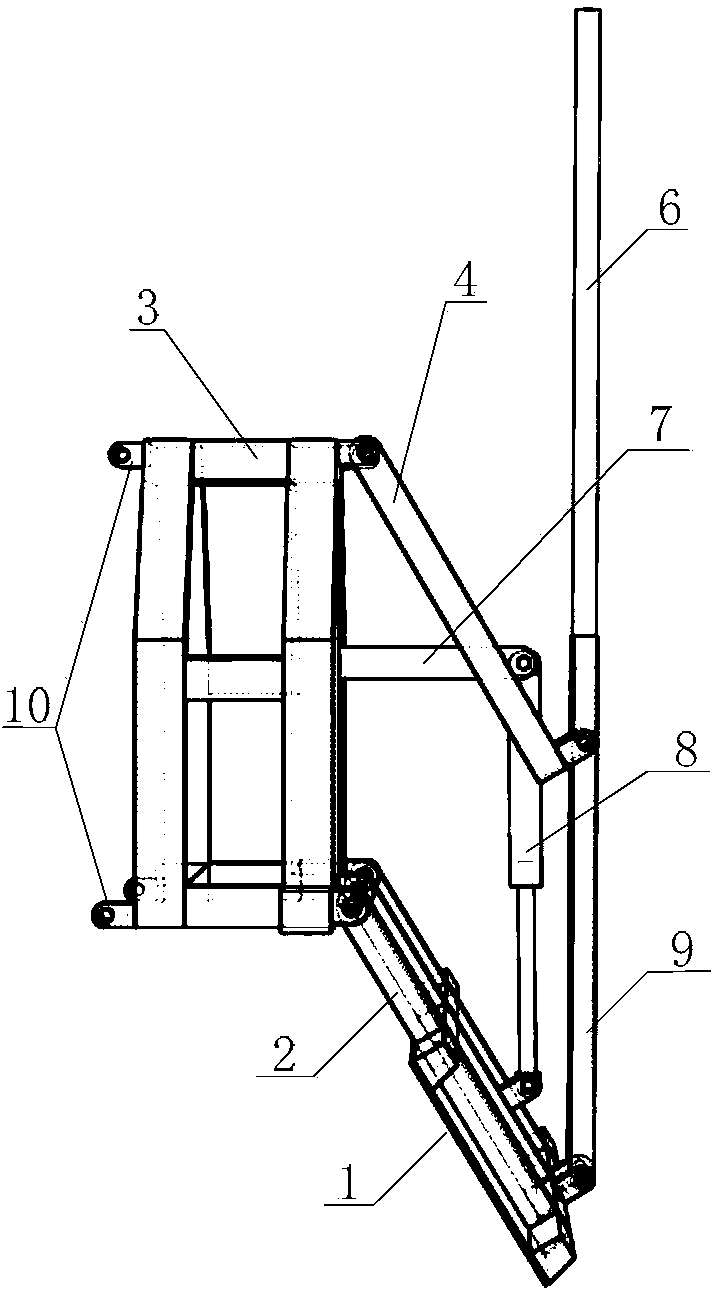

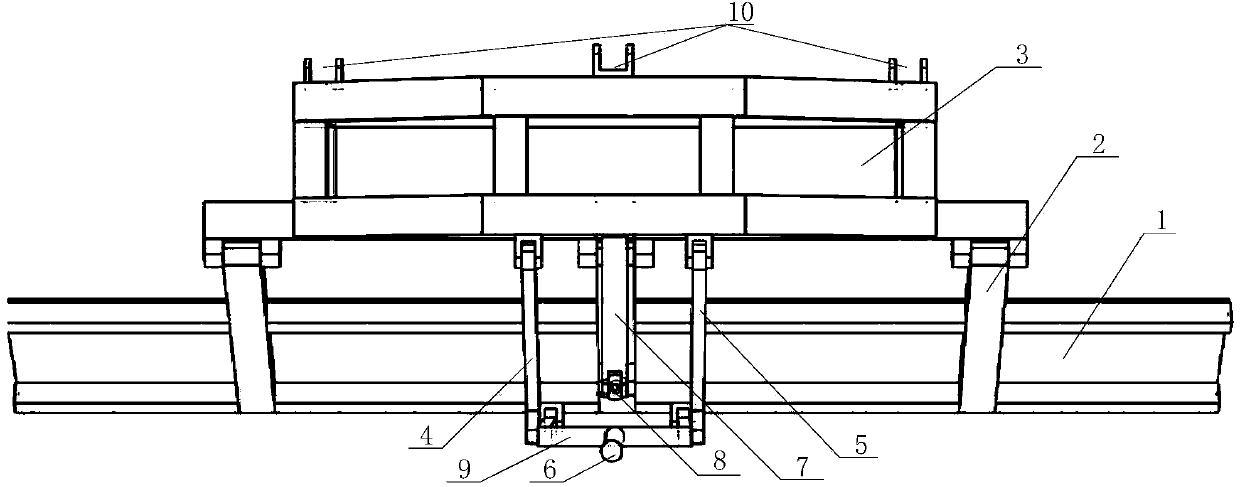

[0024] A leveling blade height adjustment mechanism of a paddy field laser grader, comprising: a leveling blade, a leveling blade turret, a suspension installation frame, a synchronous parallel bar, a synchronous movement frame, an elevation oil cylinder bracket, an elevation oil cylinder, and a receiver installation rod. The suspension installation frame, the shovel turret, the synchronous movement frame and the synchronous parallel bar constitute a parallelogram mechanism.

[0025] The front and rear end surfaces of the suspension mounting frame are arranged along the vertical direction. There is a three-point suspension interface on the front end, through which the leveling blade elevation adjustment mechanism of the paddy field laser grader is hooked to the tractor. On the rear end face, the upper end is hinged with the synchronous par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com