Wide-range speed control permanent magnet synchronous motor used for electric vehicle

A permanent magnet synchronous motor and electric vehicle technology, applied in electric vehicles, motors, electrical components, etc., can solve the problems of low working efficiency, large volume and weight, and difficult installation of the motor, so as to solve the problem of low working efficiency and improve matching sex, space-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

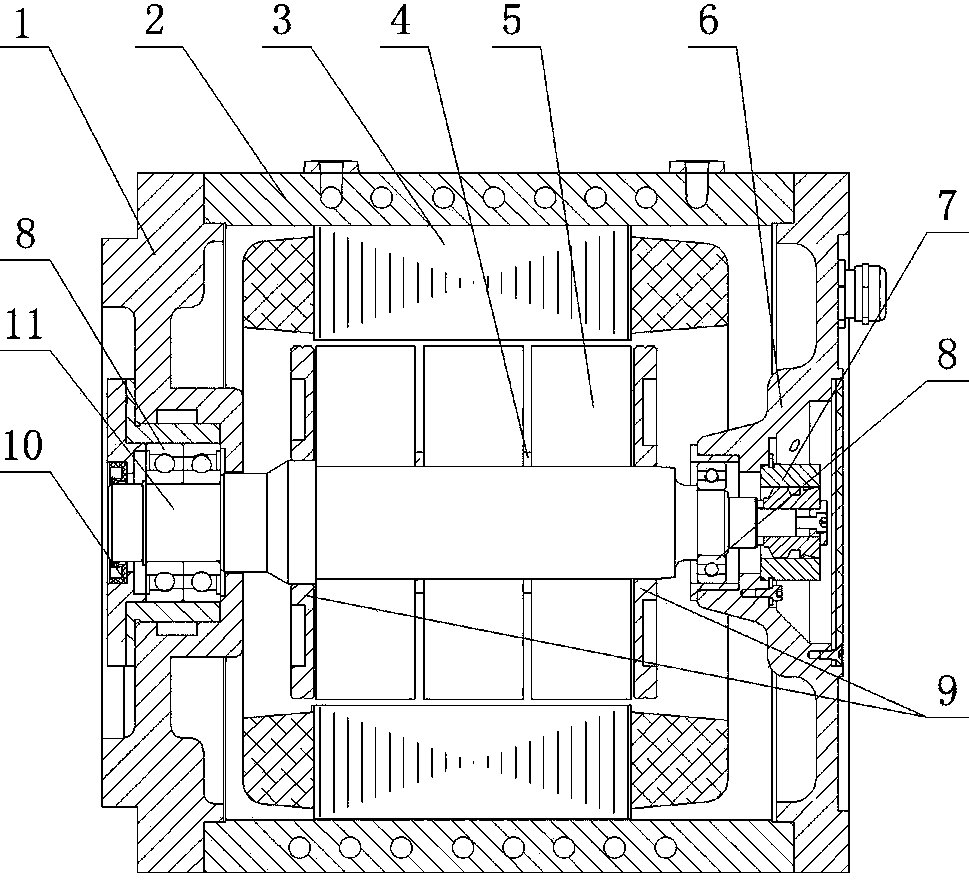

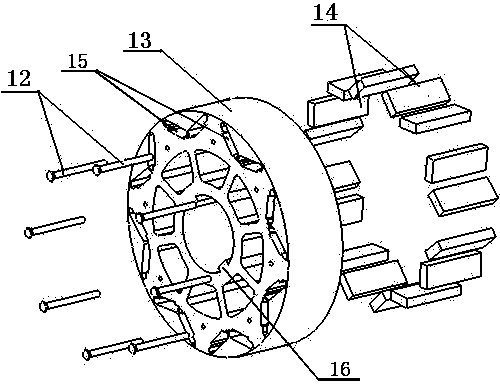

[0022] Such as Figures 1 to 2 As shown, the wide-speed adjustable permanent magnet synchronous motor used for electric vehicles in the present invention includes a housing 2, which can be air-cooled or water-cooled, and front ends are respectively installed at both ends of the housing 2. Cover 1, and rear end cover 6, stator 3 is installed inside housing 2, and the length of stator 3 decides according to actual motor length, can change, to meet practical application, on front end cover 1 and rear end cover 6 Bearings 8 are installed, and a rotor shaft 11 is installed between the two bearings 8. Three rotor modules 5 are set on the rotor shaft 11, and a spacer ring 4 is installed between the rotor modules 5. Between the rotor module 5 and the front end cover 1, And a balance ring 9 is installed between the rotor module 5 and the rear end cover 6, a sealing ring 10 is installed between the rotor shaft 11 and the bearing 8 of the front end cover 1, and the rotor shaft 11 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com