Sorting and grouping method for lithium ion batteries

A lithium-ion battery, matching technology, applied in secondary batteries, secondary battery testing, secondary battery repair/maintenance, etc., can solve problems such as high cost and complex battery sorting process, achieve long service life, reduce The occurrence of adverse phenomena and the effect of simple matching method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

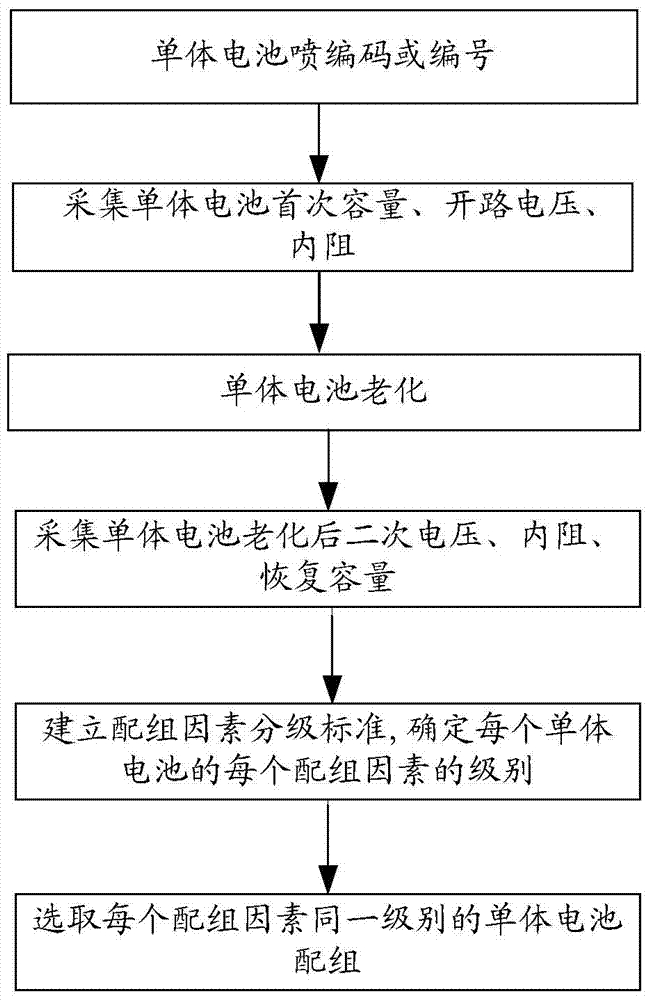

[0030] Such as figure 1 As shown, the sorting and grouping method of lithium-ion batteries of the present invention mainly includes the following steps:

[0031] 1) Coding or numbering each single battery of the same batch;

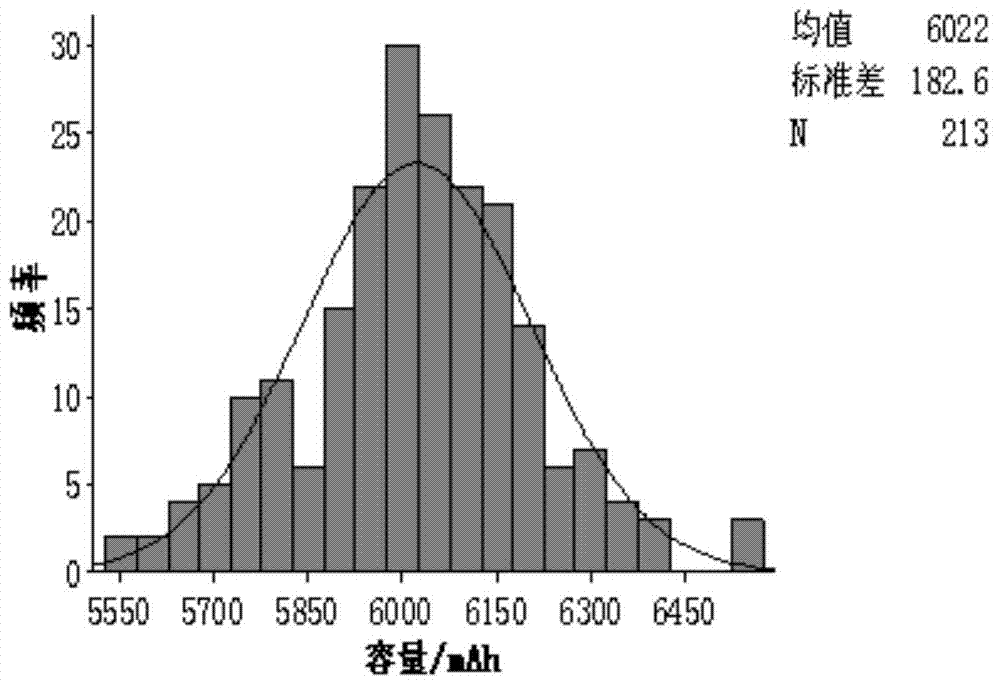

[0032] 2) Distinguish the capacity of the single battery after printing or numbering, select the single battery with a charge of 0% to 80%, measure and record the first voltage V of the above single battery 1 , internal resistance R 1 and capacity C 1 ;

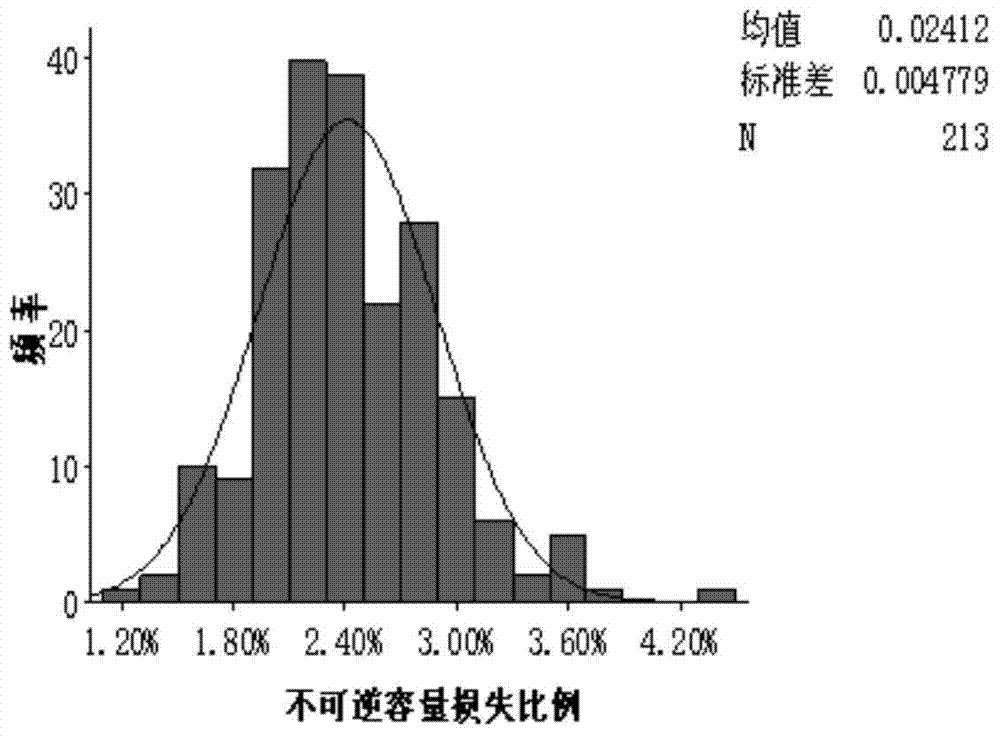

[0033] 3) Put the above single battery into the aging device, and age it for 4 hours to 30 days at a temperature of 25°C to 80°C. After the aging is completed, collect the secondary voltage V of the aged single battery 2 , internal resistance R 2 and recovery capacity C 2 , at the same time according to the recovery capacity C 2 Establish a grading standard for the recovery capacity, and at the same time grade the recovery capacity of each single battery;

[0034] 3) Statistics of voltage change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com