Device used for picking and placing IGBT lining plate

A liner and left clamping arm technology, which is applied in the manufacture of electrical components, electric solid devices, semiconductor/solid state devices, etc., can solve problems such as easy contact with chips or solder, hidden dangers of taking and placing the liner, and easy damage to the liner, etc. Achieve the effect of simple and compact structure, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

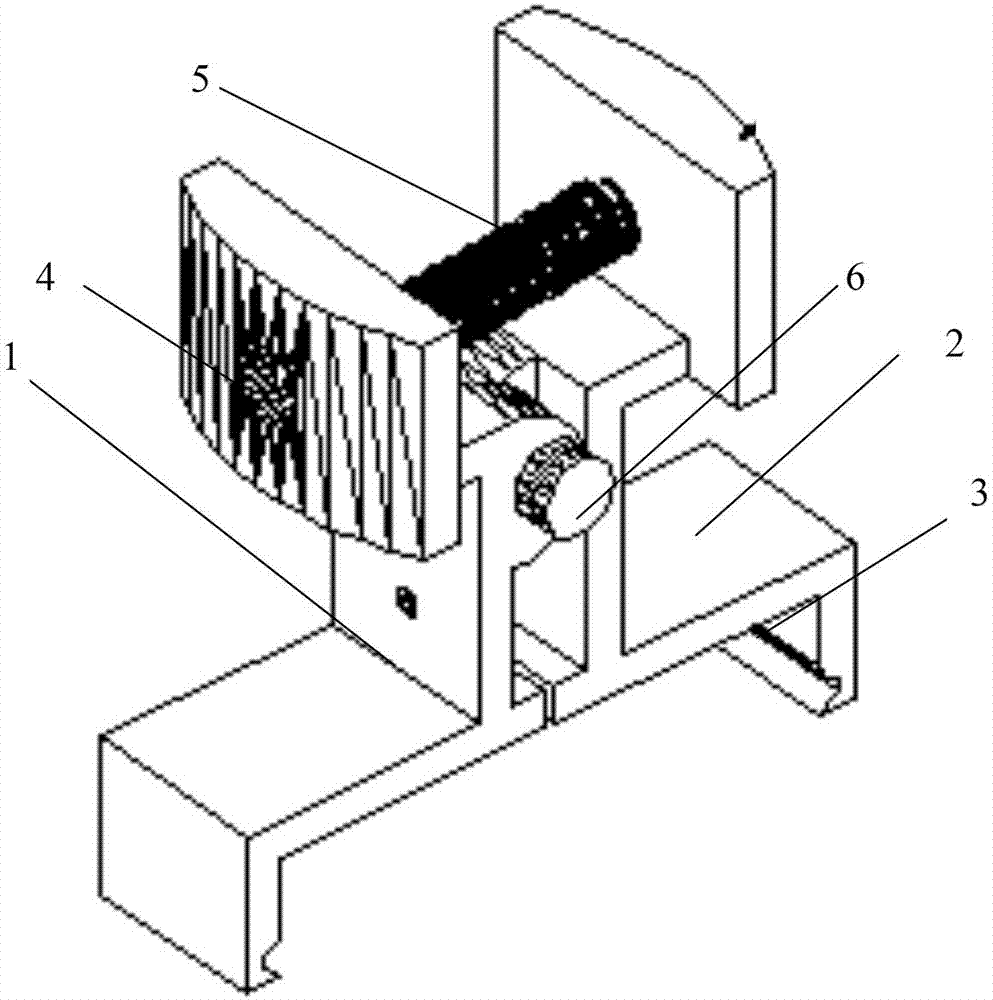

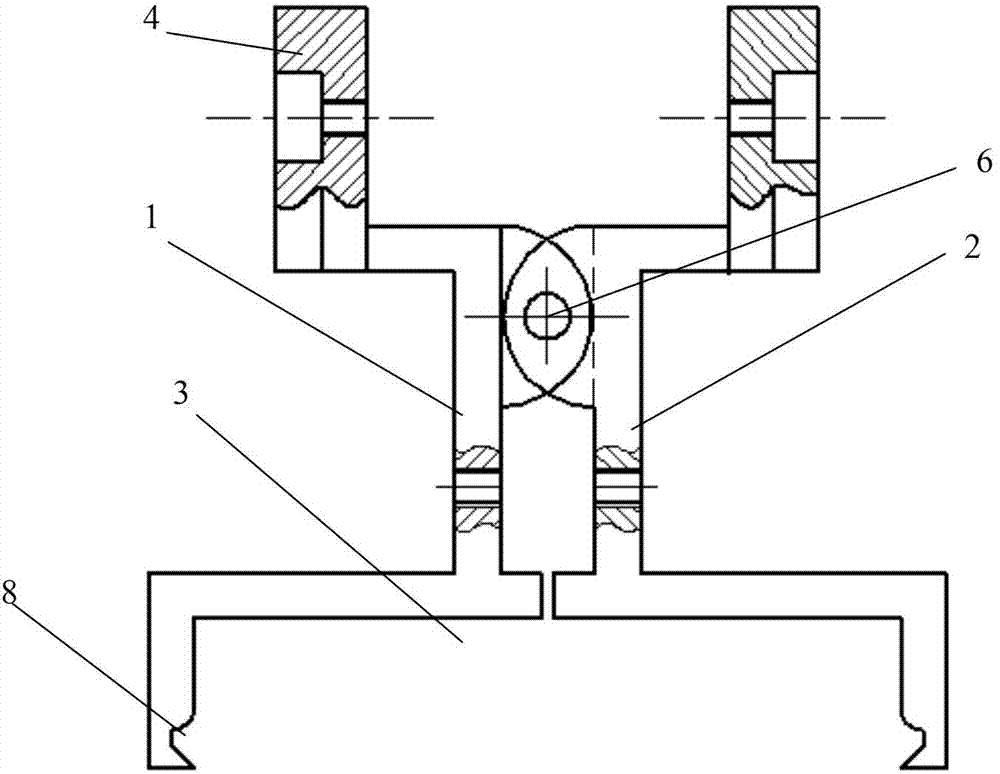

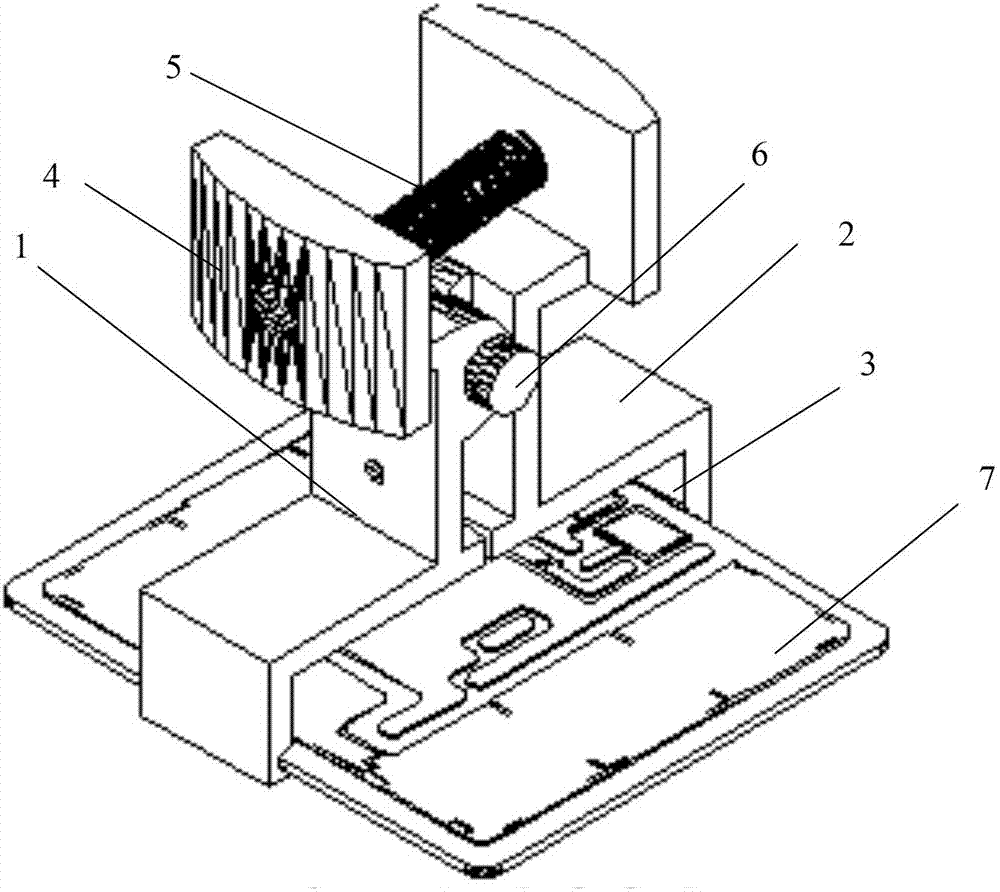

[0022] like figure 1 , figure 2 and image 3 As shown, the device for picking and placing the IGBT liner in the present invention includes a left clamping arm 1 and a right clamping arm 2, the middle parts of the left clamping arm 1 and the right clamping arm 2 are hinged together, and the left clamping arm 1 and the right clamping arm 2 are hinged together. The bottom of the right clamping arm 2 is opposite and forms a liner clamping portion 3 , and the liner clamping portion 3 cooperates with the edge of the IGBT liner 7 .

[0023] In this embodiment, a handle 4 is provided on the top of the left clamping arm 1 and the right clamping arm 2, and a return spring 5 is provided between the two handles 4, and the return spring 5 is compressed when it is not clamped. state.

[0024] In this embodiment, the middle parts of the left cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com