Active material used for capacitor electrode and preparation method of active material

A capacitor electrode and active material technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problem of high cost, achieve the effects of preventing agglomeration, simplifying the preparation process, and improving ion transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In one embodiment of the present invention, the preparation method of active material for capacitor electrode of the present invention, it comprises the following steps:

[0031] (1) Using nickel nitrate hexahydrate and / or cobalt nitrate hexahydrate as raw materials to prepare a mixed solution of 1-methyl-2-pyrrolidone and water;

[0032] (2) The mixed solution is subjected to reflux stirring and solvothermal reaction to obtain a hydroxide precursor;

[0033] (3) heat-treating the precursor to obtain nickel oxide, cobalt oxide or nickel-cobalt oxide active material;

[0034] Wherein, the prepared active material is a porous multi-level nanomaterial assembled from nanosheets.

[0035] In one embodiment, in the above step (1), nickel nitrate hexahydrate and cobalt nitrate hexahydrate are dissolved in a mixed solution containing 1-methyl-2-pyrrolidone and water. The mass fraction of the nickel salt in the mixed salt can be adjusted from 0 to 100%, and the active material...

Embodiment 1

[0050] Take 0.67g of nickel nitrate hexahydrate and 1.33g of cobalt nitrate hexahydrate and dissolve in a mixed solution containing 60mL of 1-methyl-2-pyrrolidone and 5mL of water. The above mixed solution was heated to 180°C, stirred at reflux for 2h, and cooled to room temperature. Subsequently, the obtained raw materials were transferred to a polytetrafluoroethylene reactor, solvothermally heated at 180° C. for 6 h, and then cooled to room temperature. After filtering, washing with water, and washing with ethanol in sequence, repeat three times, and finally dry to obtain the precursor. The precursor obtained in the process was heat-treated at 250° C. for 6 h to obtain a hierarchically porous binary nickel-cobalt oxide nanomaterial.

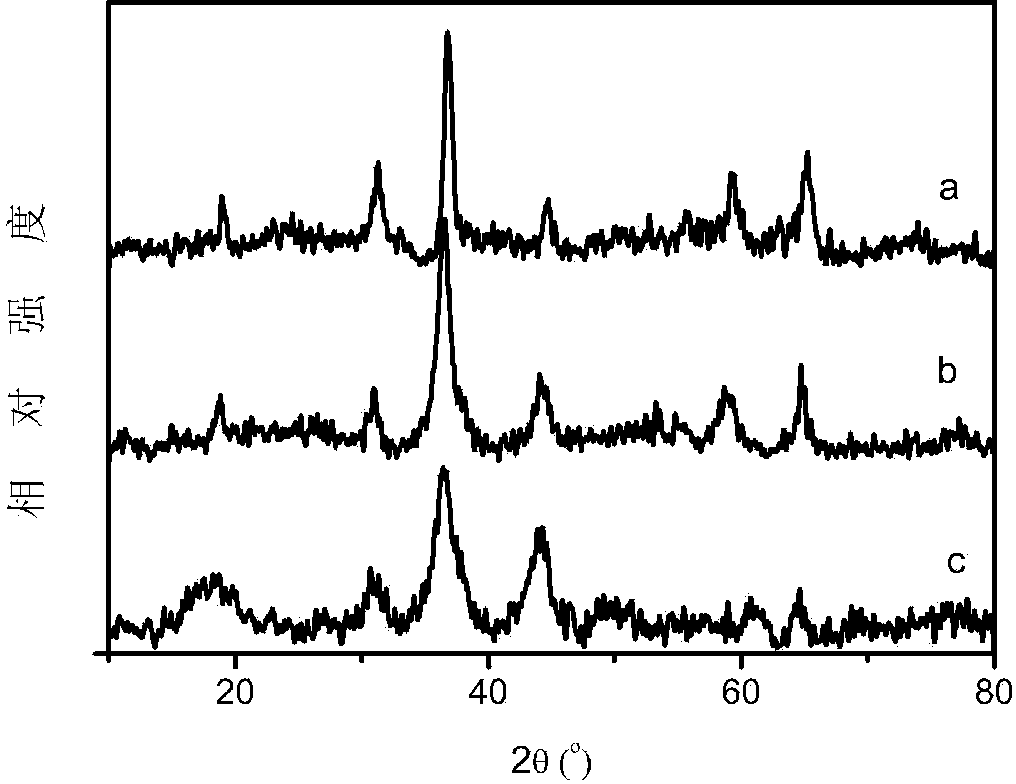

[0051] figure 1 Curve a in the middle is the XRD spectrum of the nickel-cobalt oxide prepared in this embodiment, and the peaks in the spectrum completely match the standard spectrum of nickel cobaltate. Elemental analysis also confirmed tha...

Embodiment 2

[0057] Dissolve 1 g of nickel nitrate hexahydrate and 1 g of cobalt nitrate hexahydrate in a mixed solution containing 60 mL of 1-methyl-2-pyrrolidone and 5 mL of water. The above mixed solution was heated to 180°C, stirred at reflux for 2h, and cooled to room temperature. Subsequently, the obtained raw materials were transferred to a polytetrafluoroethylene reactor, solvothermally heated at 180° C. for 6 h, and then cooled to room temperature. After filtering, washing with water, and washing with ethanol in sequence, repeat three times, and finally dry to obtain the precursor. The precursor obtained in the process was heat-treated at 250° C. for 6 h to obtain a hierarchically porous binary nickel-cobalt oxide nanomaterial.

[0058] figure 1 The middle curve b is the XRD spectrum of the nickel-cobalt oxide prepared in this embodiment, and it can be seen that the product contains both nickel cobaltate and nickel oxide. Elemental analysis confirmed that the molar ratio of nic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com