A fixture for making a current transformer and a method for making the current transformer

A technology of a current transformer and a manufacturing method, which is applied to inductors, circuits, transformers, etc., can solve the problems of affecting the coplanarity, the displacement of the ring, and the lack of effective guarantee of the coplanarity of the transformer, and achieve the guarantee Coplanarity, the effect of ensuring coplanarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

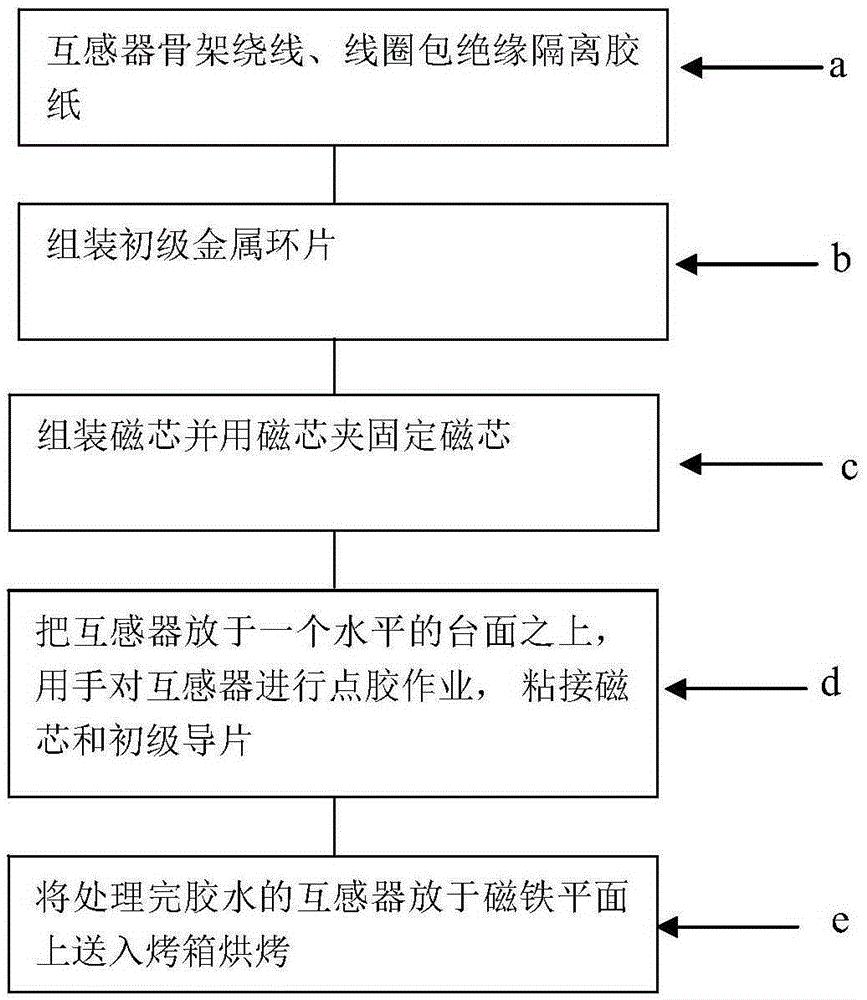

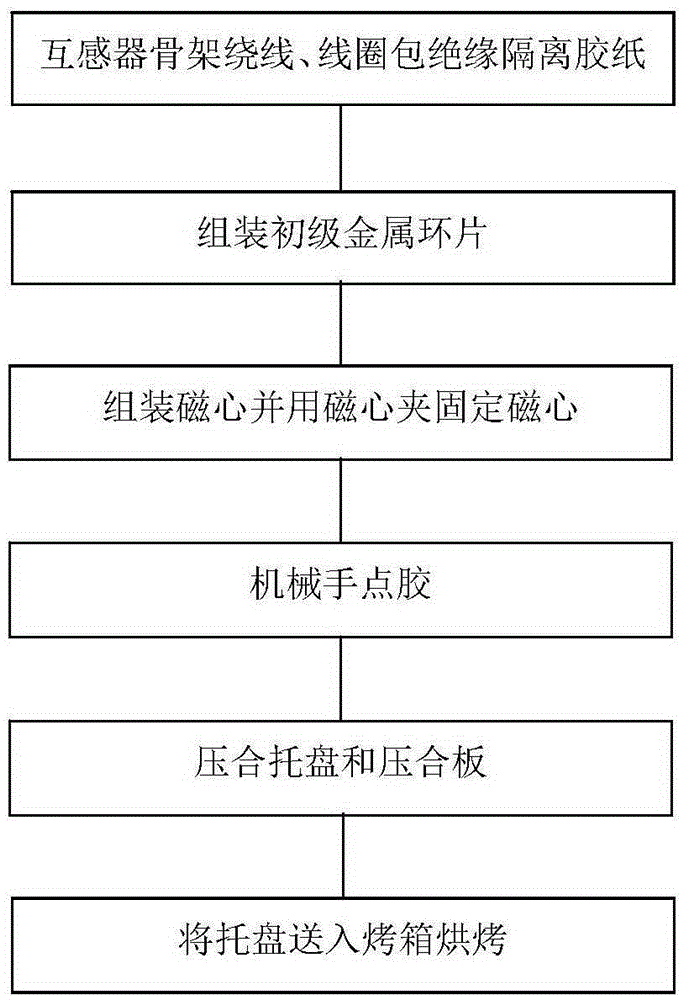

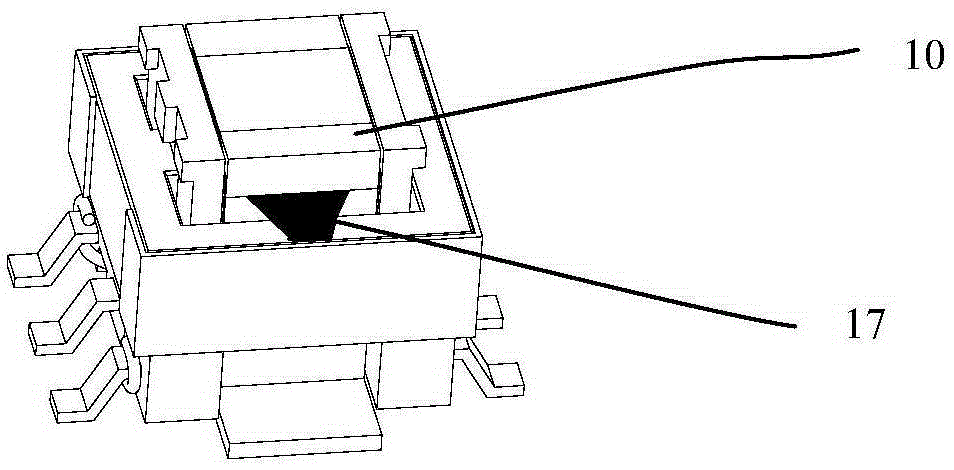

[0056] The model of the current transformer 10 in the preferred embodiment of the present invention is EE5.0. Such as figure 2 Shown, is the method that a kind of current transformer of the present invention is made, comprises the following steps:

[0057] (1). Secondary winding of the transformer skeleton, insulation and isolation tape wrapped in the coil: wind the wire 12 on the skeleton 11, hang the wire up and down on the skeleton terminal, and then wrap a circle of high temperature along the direction of the wire wrap Adhesive paper16.

[0058] (2). Assemble the metal ring piece 14 of the primary coil: Assemble the ring piece 14 on the wire package wrapped with tape.

[0059] (3). Assemble the magnetic core and fix the magnetic core with the magnetic core clamp: put the magnetic core 13 into the wire bag, and fix the magnetic core with the magnetic core clamp 15, and the direction of the magnetic core clamp needs to be uniform.

[0060] (4). Manipulator dispensing: Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com