Method for producing a striplight and striplight

A light strip and carrier technology applied to flexible LED strips. ,In the field of manufacturing light strips, it can solve the problems of high cost manufacturing of lighting devices, and achieve the effect of simple method and simple electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

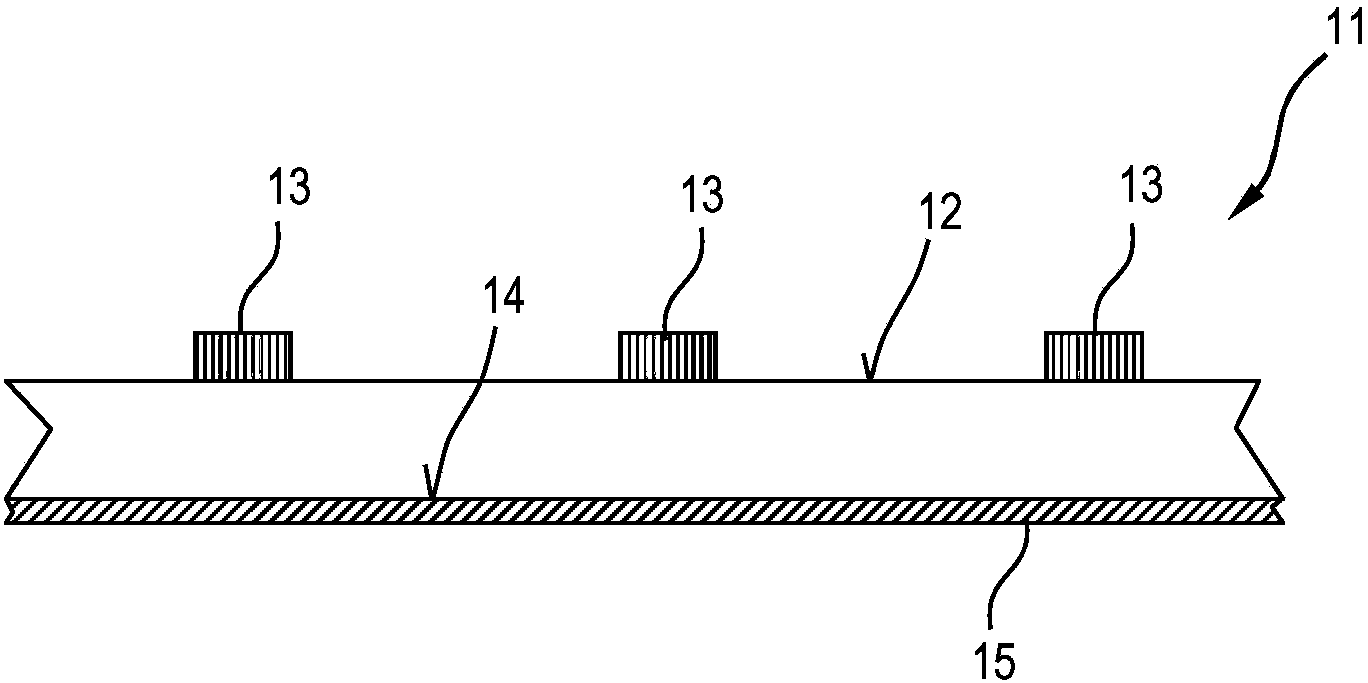

[0037] figure 1 A partial view of a strip-shaped carrier 11 is shown in side view, which is equipped with semiconductor light sources in the form of light-emitting diodes 13 on its front side 12 . The carrier 11 can, for example, be flexible and consist of polyimide. The front side 12 can also have a strip conductor structure (not shown). also like figure 2 As shown, two parallel electrical conductors 15 in the form of copper wires with a circular cross-section lie loosely on the back side 14 of the carrier 11 and are also in contact with the back side 14 .

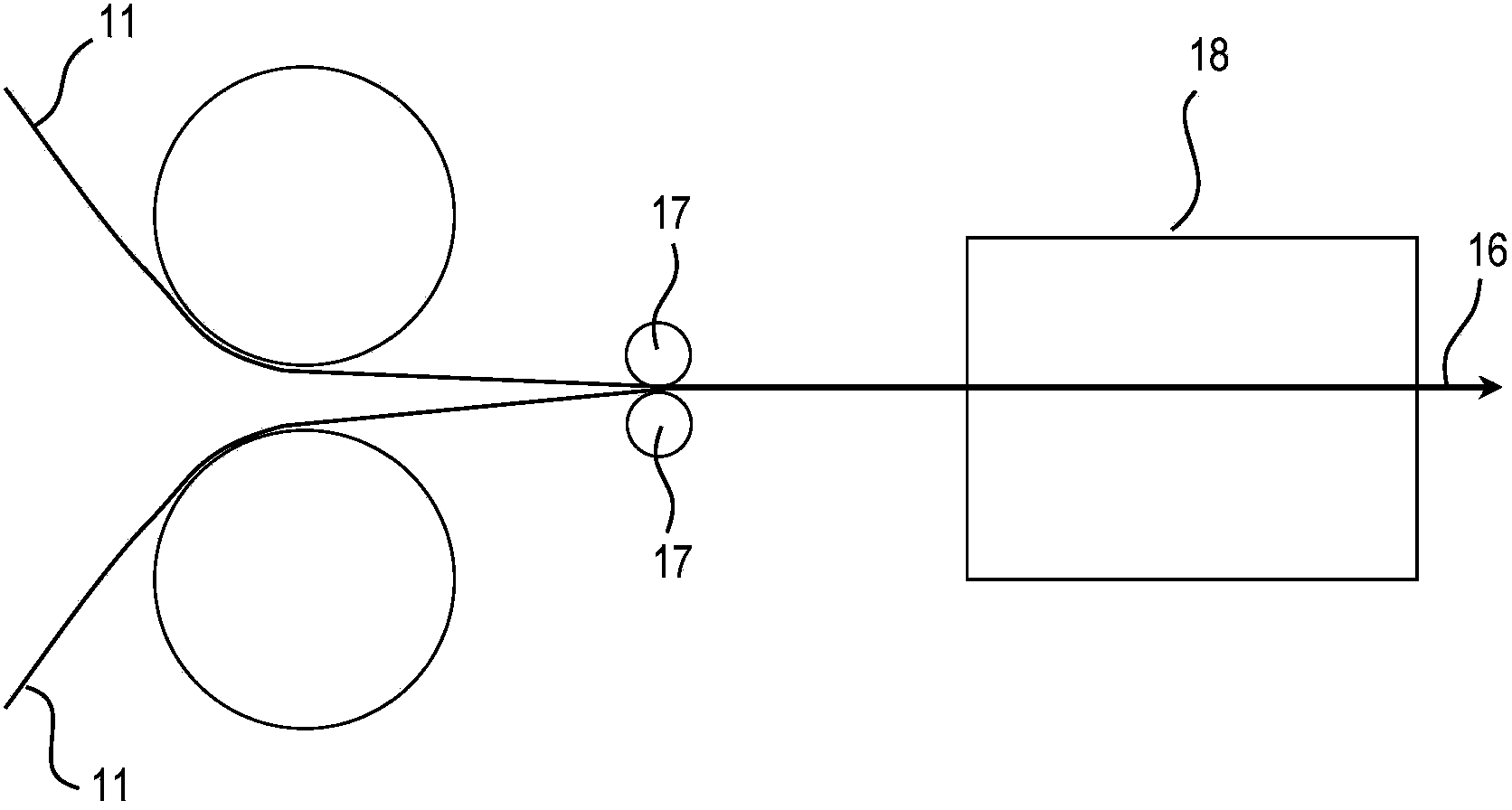

[0038] image 3 The structure used to manufacture the light bar 16 is shown. In this construction, initially an assembled strip-shaped carrier 11 and two electrical lines 15 are provided. For example, electrical wire 15 is loosely mounted on the back side 14 of carrier 11 by wire roller 17, as figure 1 or figure 2 as shown.

[0039] The elements 11 to 15 are also conveyed further into an embedding machine 18, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com