Micro differential pressure control based valve quick positioning system

A positioning system and micro-differential pressure technology, applied in the field of positioning systems, can solve the problems of low positioning accuracy, susceptibility to interference, and failure to achieve micro-differential pressure control, etc., to improve safety performance, improve control accuracy, and shorten positioning time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the invention, and detailed implementation methods and specific processes are given. The structure, location, and connection of each component can be changed. In the technical solution of the present invention Basically, all improvements and equivalent transformations of individual components based on the principles of the present invention should not be excluded from the protection scope of the present invention.

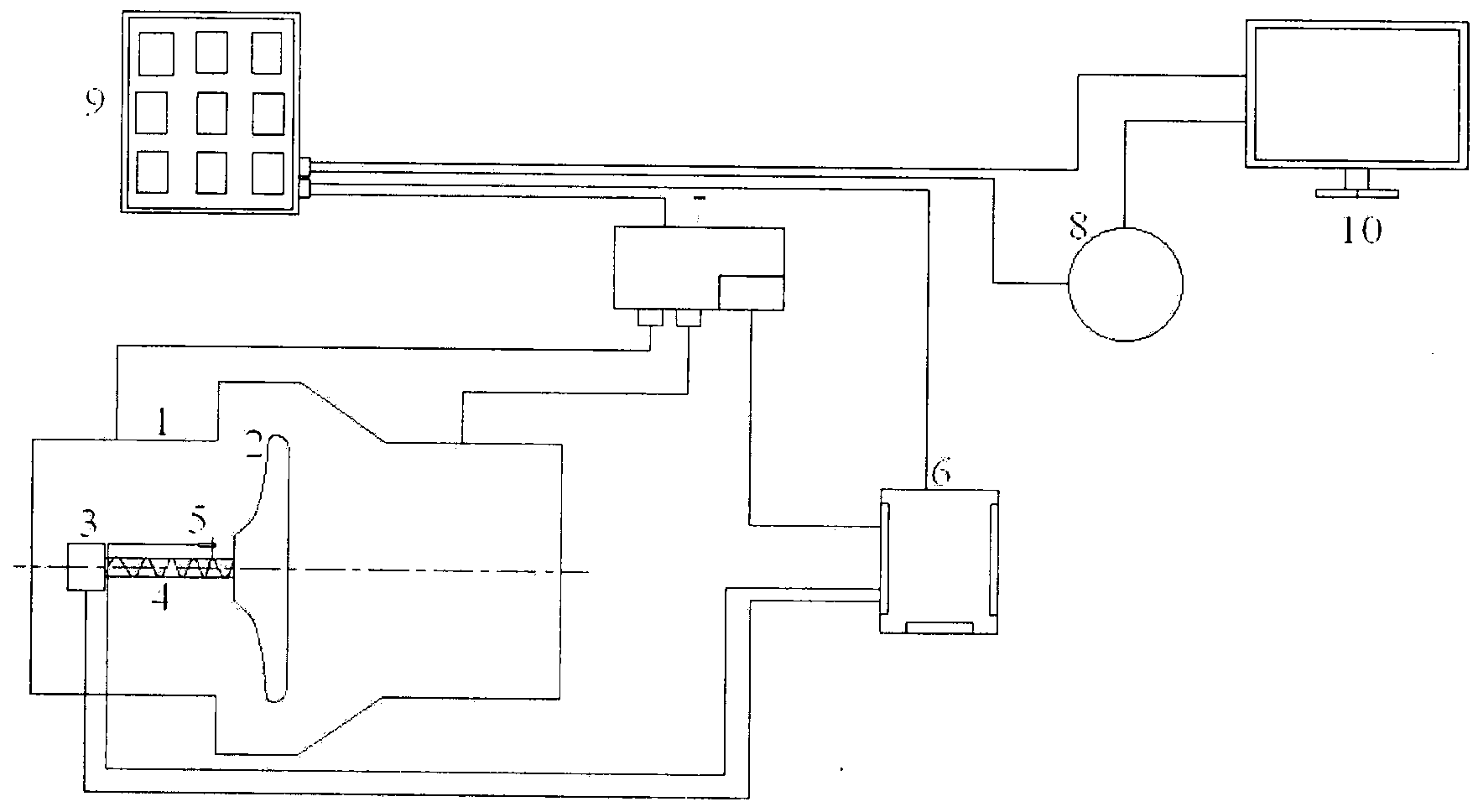

[0017] The structure of the micro differential pressure valve rapid positioning system of the present invention is as follows: figure 1 As shown, it includes: valve chamber 1, valve disc 2, stepper motor 3, sliding table screw mechanism 4, proximity switch 5, motion control and data acquisition card 6, differential pressure sensor 7, software control system 8, measurement and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com