Reinforcement construction method of the suspended ceiling system

A construction method and ceiling technology, which are applied in building maintenance, construction, building structure, etc., can solve the problems of inability to satisfy architectural aesthetics, inability to guarantee accuracy, and high-altitude work volume, etc., and achieve great promotion value, simple construction, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

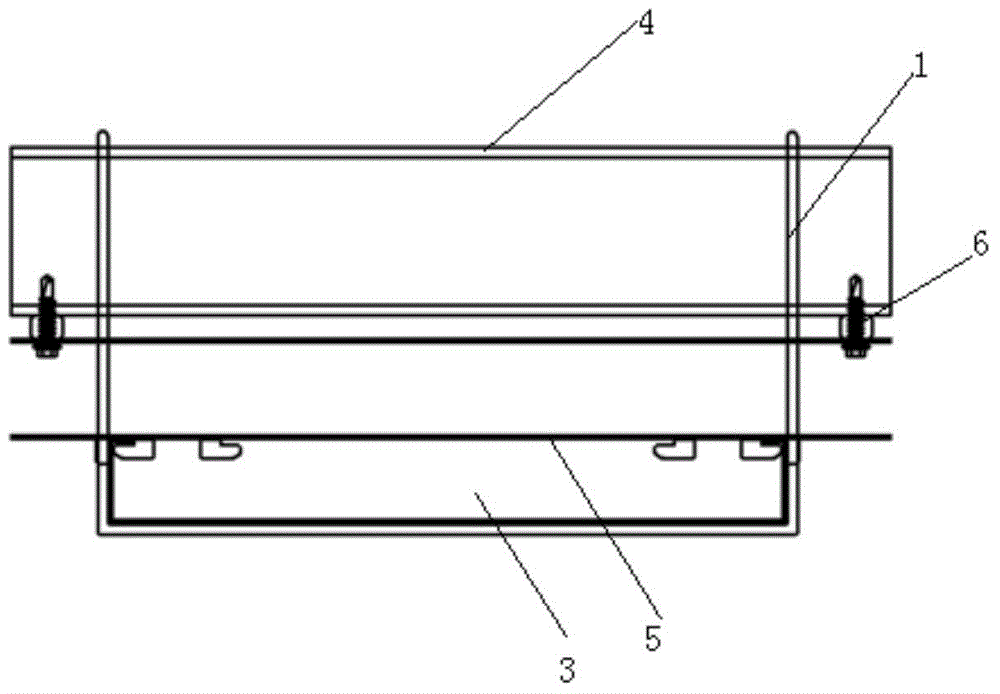

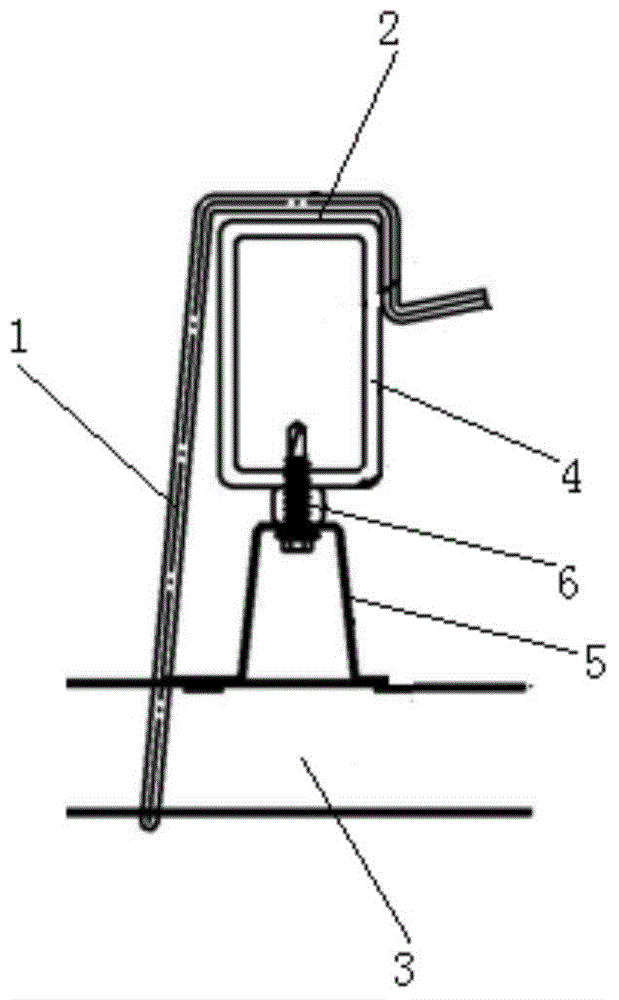

[0021] Referring to the accompanying drawings, the construction method for the reinforcement of the separated ceiling system includes the following construction steps:

[0022] 1) Steel wire clamp 1 is made of spring special steel with a diameter of φ3.0mm and steel type 72A. The steel wire clamp 1 has a bayonet 2 matching the main keel, and electrostatic powder spraying is carried out on the steel wire clamp 1. The spraying thickness is 40um;

[0023] 2) Put the steel wire clamp 1 around the 1mm thick ceiling board 3 from the lower part of the ceiling, push the upper end of the steel wire clamp 1 into the 50mm×30mm×3mm main joist 4, so that the steel wire clamp 1 and the main joist 4 are locked, and the ceiling board 3 The upper part is fixed with a snap-tooth keel 5 with a thickness of 1 mm, and the snap-tooth keel and the main keel are fixedly connected by screws 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com