Automatic material loading and unloading device and automatic navigation car match with same

An automatic navigation vehicle, automatic loading and unloading technology, applied in storage devices, transportation and packaging, etc., can solve problems such as high labor intensity, difficulty in logistics management on the production site, hidden safety hazards, etc., to reduce labor intensity, realize unmanned transportation, The effect of saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

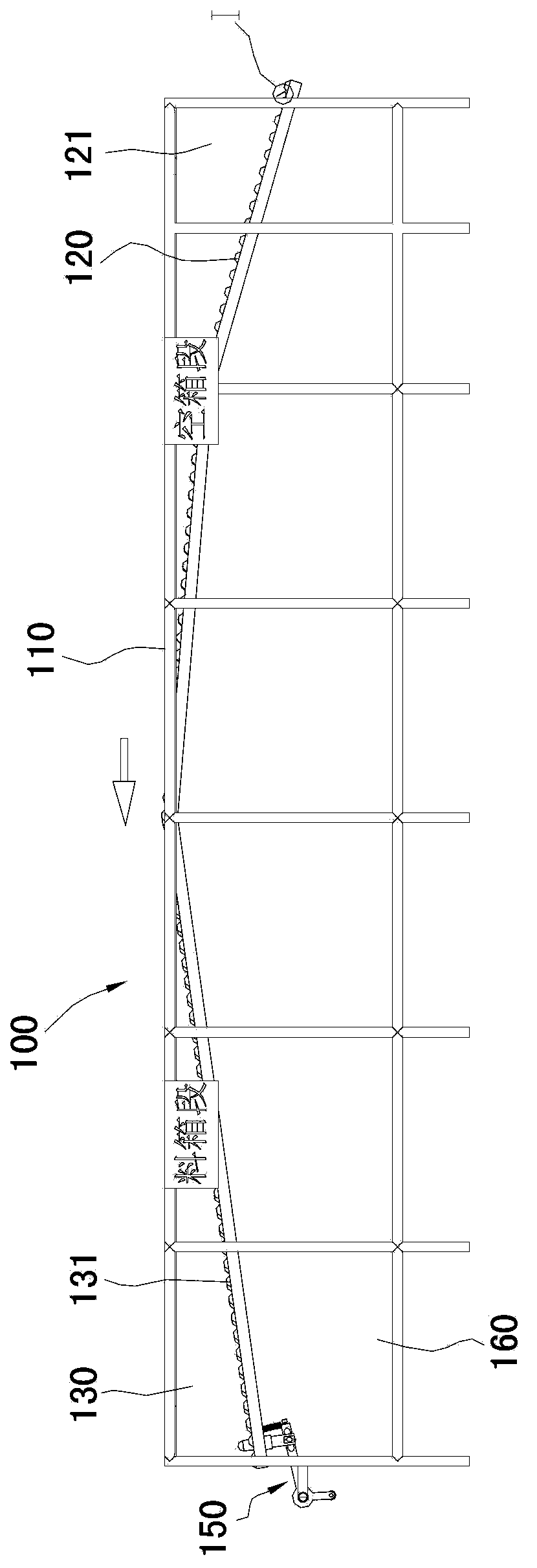

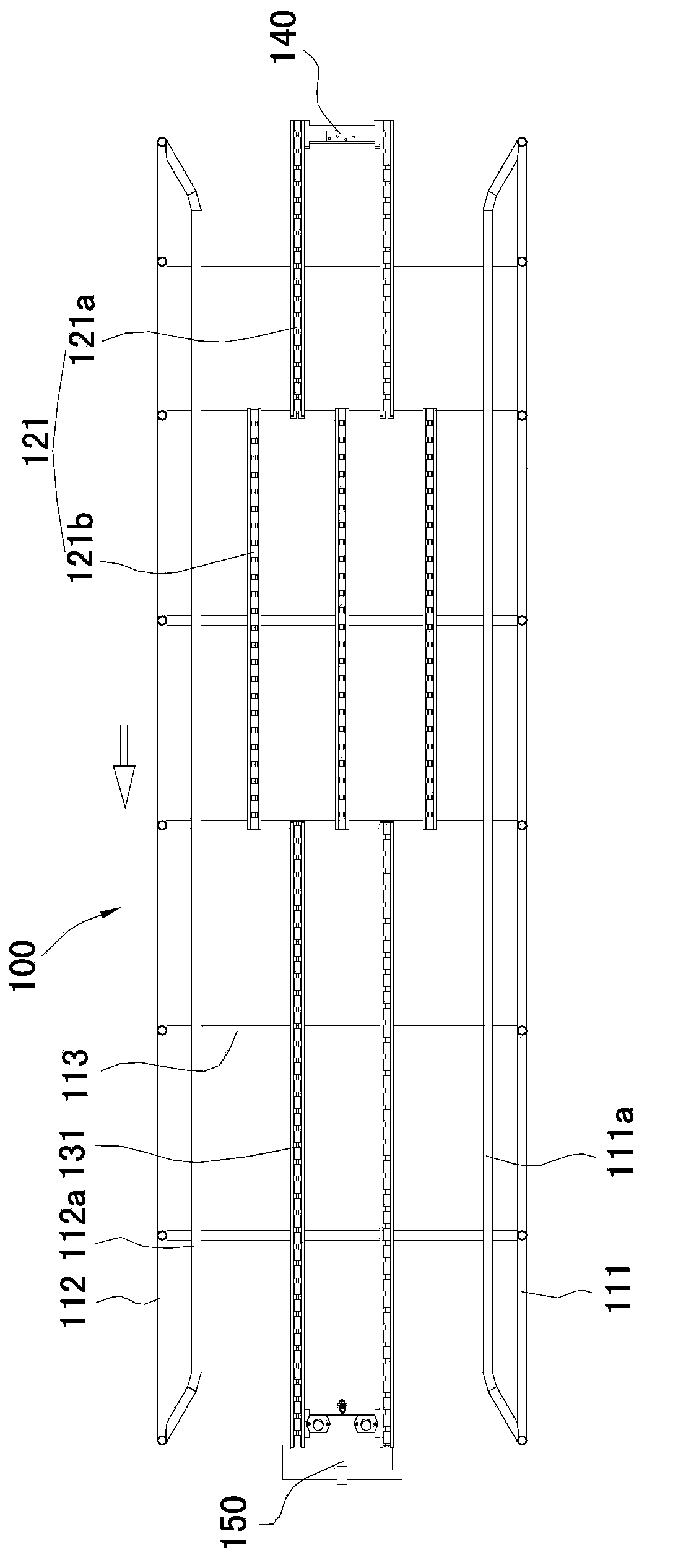

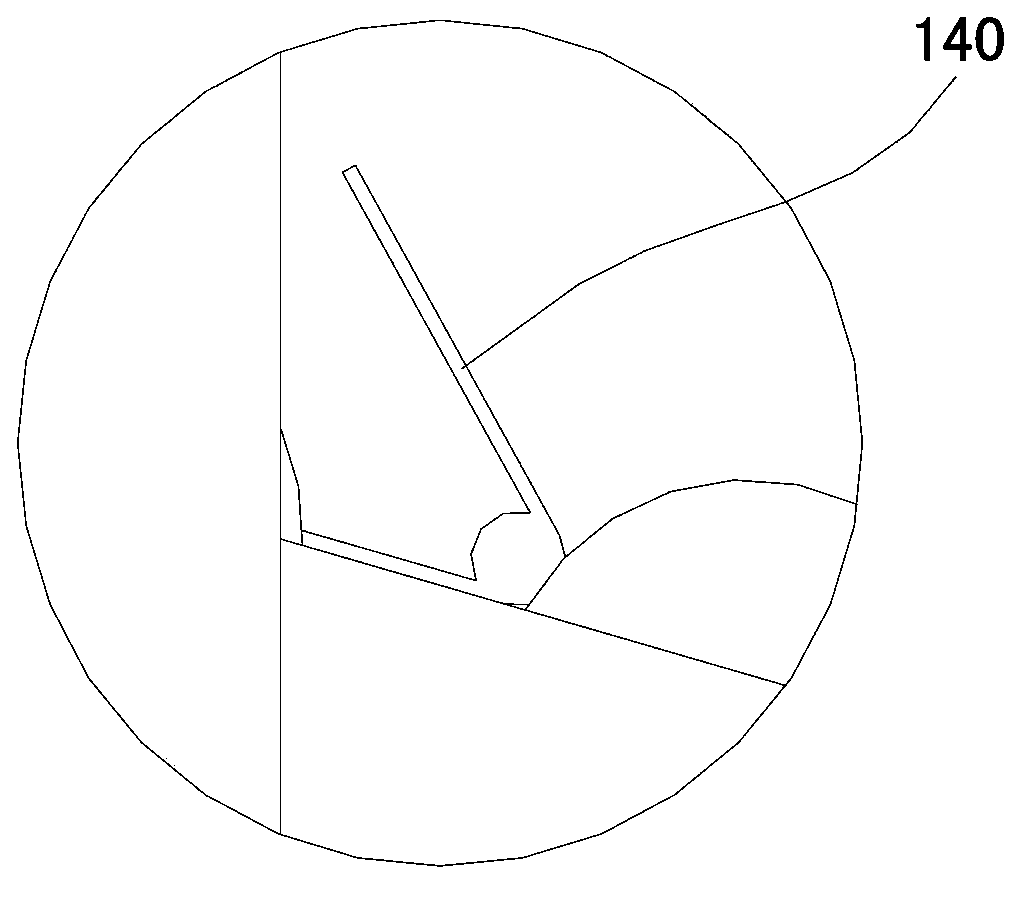

[0027] In one embodiment of the present invention, an automatic material loading and unloading device 100 is provided, such as figure 1 , 2 As shown, the material automatic loading and unloading device 100 is used for conveying box materials, and it includes a frame 110. The frame 110 consists of a first side rail 111, a second side rail 112, and a side rail 112 arranged side by side. A plurality of crossbars 113 arranged along the advancing direction of the automatic guided vehicle 200 (the direction of the arrow in the figure) between the second side rail 112 are formed, and the lower part is formed by the first side rail 111, the second side rail 112 and the cross bar 113. The navigation vehicle channel 160 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com